UV exposure, resin quality and aggregate type determine how quickly resin-bound gravel colours fade. Bold shades like red and blue tend to fade more noticeably than neutral tones. Premium resins with UV stabilisers maintain their colour longer, whilst cheaper alternatives often develop uneven patches. The mineral content matters too – quartz-based aggregates hold their colour better than limestone ones. These factors are worth considering when choosing materials for your garden path or driveway.

Key Takeaways

Bold colours like reds and blues fade quicker than neutral shades – much like how a bright red garden cushion loses its punch after a summer in the sun. This happens because of their pigment structure.

When UV rays hit the surface, they trigger chemical changes in both the resin and colour pigments – rather like how newspaper yellows when left on a windowsill.

The thinner the resin coating, the deeper UV light can penetrate, causing more damage. Think of it as wearing a thin t-shirt versus a thick jumper in the sun.

Quality matters enormously. Premium resins contain UV stabilisers that protect colours, similar to how sunscreen shields your skin. Cheaper options often skip these protective additives.

The stone type beneath also plays a crucial role. Quartz-based gravels hold their colour better than limestone or sandstone when exposed to sunlight, making them a smarter long-term choice for British weather conditions.

Understanding UV Light and Its Impact on Resin Colors

UV light significantly affects resin-bound gravel colours, and it’s crucial to understand why. Without proper UV stabilisers, resin surfaces can yellow and fade, particularly in British summers where sunshine exposure can be intense.

Bold colours like reds and blues tend to fade fastest, much like how an old garden cushion loses its vibrancy when left outside.

The thinner the resin layer or the poorer the cure, the more UV light penetrates and damages the surface. Think of it like sunscreen – a thin layer offers less protection than a properly applied coat. Excessive UV exposure can lead to significant discoloration, especially in low-quality resins.

The sun’s rays trigger chemical reactions that break down both the resin and its pigments, gradually dulling your driveway or patio’s appearance.

To maintain your resin surface’s colour long-term, opt for UV-resistant formulations. These work similarly to UV-protective coatings on outdoor furniture, helping preserve the original colour and clarity of your installation.

The Role of Resin Quality in Color Retention

Quality resin is crucial for keeping colours vibrant in resin-bound surfaces – much like using premium paint on your house exterior. Top-grade resins, especially aliphatic polyurethanes, protect against UV damage and stop colours from fading in British sunlight. Think of it as sunscreen for your resin surface.

Adding special ingredients like antioxidants and UV absorbers helps the resin resist breakdown from weather exposure. It’s similar to how a good car wax protects your vehicle’s paintwork. Tough and long-lasting pathways made with high-quality resin ensure that colour retention is maximized, enhancing the overall aesthetic appeal. Furthermore, using UV-resistant resin can significantly improve the durability and longevity of the surface.

Cheaper resins often can’t maintain their colour, leading to patchy, faded surfaces within months – particularly noticeable in garden pathways or driveways.

For any outdoor resin project where appearance matters, investing in premium resin isn’t just about durability; it’s about maintaining that fresh, well-kept look for years to come. Skimping on resin quality typically means redoing the job sooner rather than later, costing more in the long run.

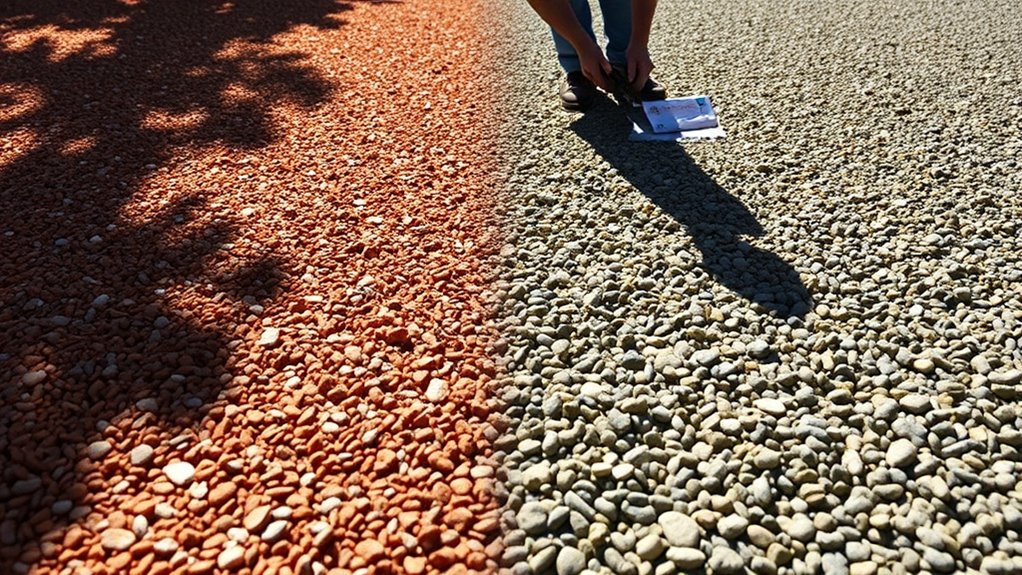

Aggregate Color and Composition: Why It Matters

Aggregate colour and composition play a vital role in how resin-bound surfaces look and last. The mineral makeup of your chosen aggregate directly affects its colour stability when exposed to UV light. Quartz-based aggregates hold their colour exceptionally well thanks to their hard structure, whilst softer materials like limestone and sandstone tend to fade more quickly. The size of aggregate particles matters too – larger pieces actually resist fading better because less of their surface is exposed to sunlight. Additionally, using UV-stable resins can enhance the longevity of the surface and prevent premature fading. This is essential in maintaining aesthetically appealing outdoor spaces over time.

| Aggregate Type | Colour Stability |

|---|---|

| Quartz-based | High |

| Limestone/Sandstone | Moderate to Low |

| Iron-rich | Susceptible to discolouration |

Environmental Factors That Contribute to Fading

Environmental factors seriously affect how resin-bound surfaces fade, impacting both looks and strength. UV rays are the main culprit, breaking down the resin’s chemical structure and causing colours to fade – particularly noticeable in lighter shades commonly used in British driveways and patios.

Our typical UK weather doesn’t help either. The constant shift between freezing winters and warm summers puts stress on the surface, whilst our frequent rainfall can weaken the resin bonds.

Those living near busy roads or industrial areas might notice faster deterioration from air pollution, and regular foot or vehicle traffic adds to the wear. Additionally, the choice of UV-stable resins can significantly influence the longevity and color retention of resin-bound gravel surfaces.

To protect your investment, regular maintenance is crucial. A bit of routine care helps fight these environmental effects and keeps your resin-bound surface looking fresh longer.

Think of it like caring for your car’s paintwork – the better you look after it, the longer it lasts.

The Importance of Installation Quality

The quality of installation makes or breaks a resin-bound surface, regardless of its looks. Proper fitting ensures your surface stays durable and keeps its colour for years to come. Getting the basics right – from choosing the correct base material to mixing the perfect resin-to-aggregate ratio – is crucial for long-term success.

Key installation requirements:

| Installation Aspect | Importance |

|---|---|

| Base Material Selection | Supports structural integrity |

| Resin Mixing Ratio | Guarantees durability and longevity |

| Adhesion Preparation | Prevents premature surface breakdown |

| Drainage Management | Prevents water retention issues |

Think of it like laying the foundations of a house – cut corners at the start, and you’ll face problems down the line. Using BBA-certified systems and regular quality checks ensures your installation meets British standards. A properly installed resin surface can last 15-20 years, whilst poor workmanship might need repairs within months.

Maintenance Practices to Preserve Color Vibrancy

Regular upkeep keeps resin-bound gravel looking vibrant.

Simply sweep weekly and give it a good rinse now and then to shift dirt and stop stains setting in.

Pop on a UV-stable sealant every 5-8 years – think of it as sunscreen for your driveway – to prevent the colour from fading in our British weather.

These basic steps will keep your surface looking fresh whilst making it last longer.

Regular Cleaning Routine

Keeping resin-bound gravel looking vibrant requires regular cleaning. A good sweep each week removes debris, whilst occasional low-pressure washing tackles stubborn dirt.

Stick to pH-neutral cleaners – they’re gentler on the surface and won’t harm the resin or colour. Skip harsh chemicals and rough scrubbing, as these can fade the colour faster.

Keep an eye out for autumn leaves and spills – sort them quickly to avoid stains. Check the surface now and then for signs of wear, especially after winter. A quick repair job keeps the colour looking even across the whole area.

With proper care, your resin-bound gravel should stay bright and fresh-looking for years to come. Think of it like caring for a carpet – the more you look after it, the longer it maintains its appearance.

Protective Coatings Application

Protective coating application is vital to maintain resin-bound gravel colour vibrancy and shield against UK weather conditions. Essential practices include:

- UV-Protective Sealants: Block harmful rays to prevent colour fade, much like sunscreen for your driveway. Most effective in exposed areas like garden paths and driveways.

- Weather-Resistant Resins: Choose resins with specialised additives to handle British weather – from summer heat to winter frost. These protect against colour loss and surface damage.

- Proper Application: Apply in thin, even coats during dry weather (ideally 15-20°C). Like painting a fence, consistency is key for lasting protection.

Best results come from thorough surface preparation and following manufacturer guidelines precisely.

Regular maintenance checks help spot areas needing touch-ups before damage occurs.

Options for Surface Protection and Restoration

Surface Protection and Restoration Options

Protective coatings are vital for maintaining resin-bound gravel surfaces across UK properties.

Common restoration methods include UV-stable overlays, which work brilliantly against our varied British weather, and specialist sealants that prevent damage from rain and frost.

Much like treating a wooden deck or patio, these protective measures help your surface stay looking fresh.

For best results, apply coatings during dry weather and ensure thorough cleaning beforehand – a bit like prepping walls before painting.

Regular maintenance keeps driveways and paths looking smart whilst saving money on major repairs down the line.

Protective Coating Benefits

Protective Coatings: Key Benefits

Protective coatings do more than just make resin-bound gravel look good – they’re vital for long-term surface protection.

These practical benefits help you make smart choices about coating types and application:

- Colour Protection: Quality UV-resistant coatings stop your aggregate surface from fading in the British sun, much like a good garden fence treatment.

- Fights Staining: Creates a barrier against common UK nuisances like motor oil, fallen leaves and winter road grit, keeping your surface clean and protected.

- Wear Resistance: Forms a tough layer that handles daily foot traffic and car movements, similar to a hard-wearing kitchen floor coating.

Less wear means less upkeep and longer life.

Restoration Techniques Explained

Restoring resin-bound gravel is straightforward when you know the proper techniques.

Start by cleaning the surface thoroughly with a stiff brush or pressure washer – much like scrubbing a dirty patio. Once bone-dry, remove any damaged bits of resin and loose gravel.

Mix your resin according to the manufacturer’s guidelines, taking care to match the colour precisely (think matching paint for touch-ups). For deeper cracks, build up layers gradually, letting each one set properly.

If your surface has lost its colour, opt for UV-resistant resins and colour-matching products – they’re worth the extra cost to prevent future fading.

Finish with a quality sealant to guard against wear and tear. Pop on a fresh UV-protective coat yearly, just as you’d protect garden furniture, to keep the surface looking fresh.

Frequently Asked Questions

How Do Different Climates Affect Resin Color Fading Rates?

Different climates significantly influence how quickly resin colours fade. High temperatures in places like Brighton’s sunny seafront can speed up deterioration, whilst damp conditions common to Manchester or Glasgow may cause unwanted discolouration. Poor UV protection or improper installation makes these effects worse, particularly during British summer heatwaves or in coastal areas with high moisture levels.

Can Certain Cleaning Products Accelerate Fading in Resin Surfaces?

Strong cleaning products can damage resin surfaces much like harsh chemicals would spoil a watercolour painting. Stick to gentle detergents to protect your resin finishes and keep their colours looking fresh for longer.

What Specific Pigments Are Most Prone to Fading?

Natural and organic pigments fade rapidly when exposed to UV light. Common examples include plant-based dyes like madder root and woad. Synthetic pigments, particularly azo dyes found in coloured resin driveways, also suffer from UV damage and lose their vibrancy over time. Both types need proper UV protection to maintain their colour.

Do Darker Colors Require Different Maintenance Than Lighter Ones?

Darker colours typically need less upkeep, maintaining their shade about 30% better than lighter ones. Whilst light colours often need regular cleaning, darker shades require more focus on checking for general wear and tear to spot any signs of fading or discolouration early on.

How Often Should Protective Coatings Be Reapplied for Optimal Results?

For optimal results, protective coatings should be reapplied every 2-3 years. Set up a regular maintenance programme based on foot traffic, British weather conditions and surface wear. Heavy-use areas, such as driveways or commercial spaces, may need more frequent attention, whilst sheltered pathways could stretch to longer intervals.

Conclusion

The longevity of resin-bound gravel colours depends on several key factors worth noting. UV rays can fade colours by up to 30% within the first year alone – a significant change noticeable in most driveways and paths. Using premium resins, selecting suitable aggregates and keeping up with basic maintenance will help preserve the colour depth. Think of it like a garden fence: proper treatment and care make all the difference in keeping it looking fresh. Whilst the initial cost might be higher for quality materials, they’re a sound investment for lasting colour retention.