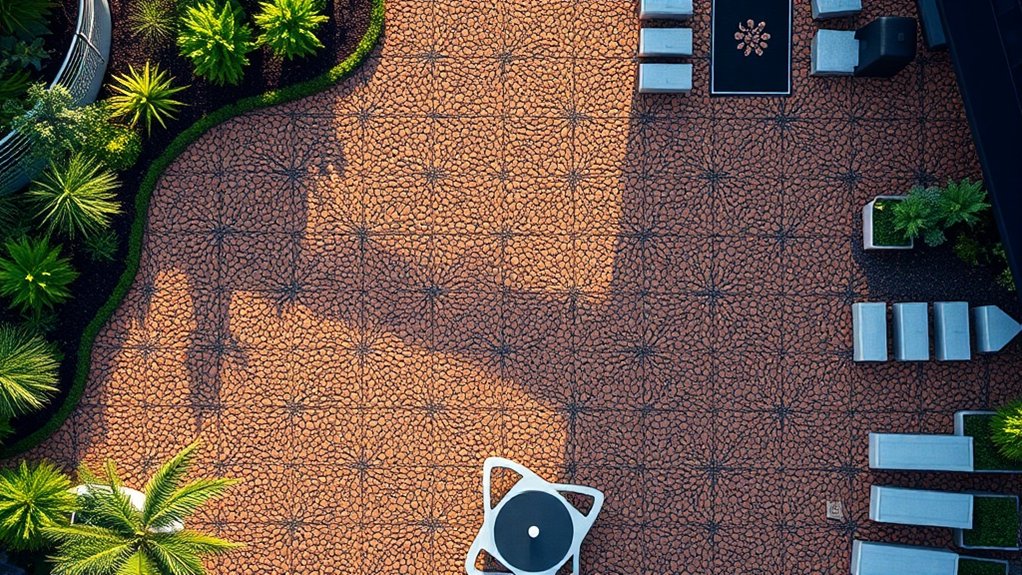

Commercial developers favour resin-bound gravel surfaces for several reasons. They are incredibly durable, lasting up to 25 years with minimal upkeep. These surfaces are highly permeable, which significantly reduces surface runoff and helps meet drainage regulations essential for obtaining planning permission. Their natural slip resistance ensures safety in all weather conditions, and the wide range of aesthetic options allows for branding flexibility. Choosing resin-bound gravel not only leads to long-term cost savings but also supports sustainability efforts. It’s a smart choice with numerous benefits to consider.

Key Takeaways

- Resin-bound gravel surfaces are highly durable, lasting between 15 to 30 years with proper maintenance, which helps developers save on long-term replacement costs.

- Their permeability greatly reduces surface water runoff, allowing for compliance with Sustainable Drainage Systems (SuDS) regulations and easing the planning permission process for commercial projects.

- With low maintenance needs, including straightforward cleaning and natural resistance to weeds, they are perfect for busy commercial areas.

- The textured finish offers excellent slip resistance, ensuring pedestrian safety in various weather conditions.

- Their aesthetic appeal, with a range of customisable designs and colours, enables developers to create unique spaces that reflect their brand identity.

Durability and Longevity of Resin-Bound Gravel

When considering the longevity of resin-bound gravel surfaces, they typically last between 15 to 25 years with proper installation and maintenance. The key to achieving this impressive lifespan is the quality of materials and installation. High-quality components can extend their service life to around 30 years. In comparison, resin-bonded alternatives last only 10 to 15 years, making resin-bound surfaces the better option. Factors such as climate, usage intensity, and regular maintenance play important roles as well. It’s crucial to focus on proper base preparation and mix ratios to boost durability. With minimal upkeep, including periodic resealing and prompt weed removal, you can keep your resin-bound gravel functional and visually appealing for many years. Additionally, the average lifespan of resin-bound driveways significantly surpasses that of many traditional paving options, further solidifying their preference among commercial developers. Regular maintenance practices, such as routine checks, will help identify issues before they become major problems.

Permeability and Drainage Compliance Benefits

Resin-bound gravel surfaces deliver outstanding durability and excel in permeability and drainage compliance.

These surfaces are specifically designed to improve stormwater management.

Here are three key benefits:

- Reduced Runoff: They can cut surface water runoff by over 50% compared to traditional surfaces, which helps to lower flood risks.

- Natural Drainage: Water seeps through the surface, preventing puddles and aiding groundwater recharge, which is crucial during dry spells. This ensures that thousands of litres of water can pass through every square metre per hour, thereby contributing to the replenishment of groundwater in urban areas.

- Sustainable Compliance: They comply with UK Sustainable Urban Drainage Systems (SuDS) regulations, simplifying planning permissions for commercial projects.

Low Maintenance Requirements for Commercial Use

Maintaining resin-bound gravel surfaces is simple and efficient, making them perfect for commercial use. With low maintenance requirements, you can keep your surfaces looking clean and vibrant. Regular cleaning, such as sweeping and light pressure washing, effectively removes debris without harming the surface. Using mild, pH-neutral detergents helps maintain the resin’s integrity during cleaning. Plus, the natural weed resistance of these surfaces means less time spent on weed management. Regularly applying eco-friendly weedkiller can assist in effective weed control. Seasonal checks of drainage systems can help catch any potential issues early, ensuring the longevity of your investment. Additionally, regular upkeep improves aesthetics and prevents costly issues over time.

Enhanced Safety and Slip Resistance Features

When it comes to safety in your spaces, resin-bound gravel surfaces provide excellent slip resistance, keeping users safe in various conditions.

You can tailor the surface texture to improve grip, ensuring it suits the specific demands of your environment. This means creating a safer area for everyone, whether they’re walking or driving.

Natural Slip Resistance

To ensure safety on surfaces, resin-bound gravel surfaces offer excellent natural slip resistance. Here are some key benefits:

- Natural Texture: The embedded aggregates provide a textured finish that enhances grip, helping to prevent slips even when wet.

- Consistent Performance: Resin-bound surfaces retain their slip-resistant qualities in both dry and rainy weather, making them suitable for the UK’s varied climate.

- Proven Testing Compliance: All blends conform to BS 8204-6:2008+A1:2010 standards for slip resistance, making them appropriate for pedestrian and light vehicular traffic.

Opting for resin-bound gravel not only improves the look of your space but also significantly enhances safety.

With its effective slip prevention and durable performance, you can rely on these surfaces.

Customizable Surface Texture

Customisable surface textures in resin-bound gravel enhance both the aesthetic appeal and safety of your surfaces.

With a wide selection of aggregate colours and textures, you can easily tailor the look to suit your project’s needs. Dark stones create a wet-look effect, improving visual traction, while angular aggregates ensure a consistent mix for optimal performance.

Incorporating crushed glass into the surface boosts slip resistance, making it perfect for damp areas. This blend of style and safety ensures your surfaces aren’t only attractive but also practical, meeting the demands of various commercial settings while prioritising user safety.

Safe for All Users

Resin-bound gravel surfaces are an excellent choice for safety, offering impressive slip resistance and permeability.

Here are three key benefits:

- Enhanced Slip Resistance: Most blends have a low slip potential, with SRV values ranging from 39 to 47, ensuring safety even in wet conditions.

- Permeability: These surfaces allow water to drain effectively, reducing standing water and minimising slip hazards, particularly during rain or frost.

- Accessibility Features: Anti-slip additives can be added in high foot traffic areas, ensuring safety without sacrificing appearance.

Aesthetic Appeal and Customization Options

Resin-bound gravel surfaces not only improve the visual appeal of commercial properties but also provide excellent options for customisation to meet various design needs. With a wide range of natural stone aggregates and colours, you can create a look that aligns with your branding and effectively utilises colour psychology.

| Feature | Benefit |

|---|---|

| Colour Variety | Extensive range from earthy tones to vibrant shades |

| Custom Blends | Tailor to match specific branding or themes |

| Seamless Finish | Creates a smooth and polished appearance |

| Design Flexibility | Offers unique shapes and textures |

| Long-lasting Vibrancy | UV-resistant pigments ensure colour stays bright over time |

Environmental Considerations in Installation

When considering a resin-bound gravel surface for your property, it’s important to note the environmental benefits it offers. This choice not only utilises sustainable materials but also reduces ecological impact.

Here are three key advantages:

- Water Management: The fully permeable surface effectively manages rainwater, helping to minimise flooding and prevent soil erosion.

- Groundwater Recharge: Rainwater seeps through the surface, replenishing local groundwater supplies and supporting plant growth, which is essential for a healthy ecosystem.

- Regulatory Compliance: These installations adhere to current building regulations, which can save you from costly drainage systems and promote sustainable urban drainage practices.

Cost-Effectiveness Over Time

Investing in resin-bound gravel surfaces may appear daunting due to the higher initial costs, but the long-term savings can significantly outweigh these expenses.

When you analyse the investment, you’ll discover that lower maintenance and repair costs enhance overall cost efficiency over time. For instance, resin-bound surfaces require minimal upkeep—there are no loose stones to replace and less weed growth—resulting in fewer ongoing costs.

Their durability also extends their lifespan, reducing the need for replacements and spreading the initial investment across many years.

A lifecycle assessment shows that while traditional paving might seem cheaper at first, the hidden costs of repairs and maintenance can add up quickly.

In the end, resin-bound gravel surfaces are a smart investment for your commercial projects.

Compliance With Sustainable Urban Drainage Systems

Choosing resin-bound gravel surfaces not only enhances the look of your property but also ensures compliance with Sustainable Urban Drainage Systems (SuDS) standards.

This is crucial for managing water effectively and reducing flood risks in urban areas that often experience heavy rain.

By selecting these permeable surfaces, you’re making a positive contribution to environmental sustainability.

Plus, they simplify the installation process and help you navigate regulatory requirements with ease.

Effective Water Management

Urban development can complicate effective water management, but resin-bound gravel surfaces present a sustainable solution that meets Sustainable Urban Drainage Systems (SUDS) standards.

These surfaces are beneficial for water retention and pollution reduction due to their porous nature. Here’s how they perform:

- Natural Infiltration: Rainwater seeps through the surface, allowing it to soak into the ground and reducing runoff.

- Pollutant Filtration: As water filters through, contaminants are removed, enhancing groundwater quality and decreasing surface water pollution.

- Regulatory Compliance: Local authorities often favour these surfaces, making it easier to obtain planning permissions and reducing the need for extensive drainage infrastructure.

Opting for resin-bound gravel not only adheres to regulations but also promotes sustainable water management in urban areas, benefiting both developers and the environment.

Flood Risk Reduction

As urban areas in the UK face growing flood risks from climate change and rapid development, using resin-bound gravel surfaces can significantly improve flood risk management.

These surfaces can reduce stormwater runoff by more than 90%, easing the burden on urban drainage systems. With permeability rates of 850-1000 litres per square metre per hour, resin-bound gravel can handle heavy rainfall, delaying peak flood times.

This not only decreases the chance of localised flooding but also strengthens the resilience of urban infrastructure. By adhering to Sustainable Urban Drainage Systems (SuDS) guidelines, these surfaces fulfil regulatory requirements and contribute to effective flood management strategies.

Therefore, opting for resin-bound gravel is a wise decision for developers aiming to reduce flood risks and enhance site safety.

Environmental Compliance Benefits

With the growing emphasis on sustainable development, choosing resin-bound gravel surfaces not only boosts visual appeal but also ensures compliance with Sustainable Urban Drainage Systems (SuDS) standards.

This option provides several environmental advantages:

- Groundwater Recharge: The porous structure of resin-bound gravel allows rainwater to soak through, helping to replenish local groundwater and support wildlife.

- Pollution Reduction: As rainwater filters through, it naturally removes harmful pollutants, resulting in cleaner water sources and healthier ecosystems.

- Planning Benefits: Meeting SuDS requirements can simplify the approval process, easing regulatory challenges and speeding up project timelines.

Performance Under Extreme Weather Conditions

Understanding the performance of resin-bound gravel surfaces in extreme weather is crucial for outdoor installations. These surfaces are known for their impressive adaptability. Their flexible composition allows them to handle freeze-thaw cycles without cracking, and their permeability prevents water build-up that can cause subsurface damage.

A well-constructed base layer ensures effective drainage, which helps to minimise the risk of frost heave.

When installing, it’s vital to consider temperature sensitivity; optimal conditions lead to stronger bonds. Resin surfaces also resist high heat and UV exposure, maintaining their structural integrity and colour even in harsh climates.

Versatility in Design and Application

Choosing resin-bound gravel surfaces opens up a variety of design options and practical uses.

Available in an array of colours, textures, and shapes, you can tailor the look to suit your environment.

Whether for a busy retail area or a peaceful garden pathway, these surfaces are versatile enough to fulfil both functional and aesthetic requirements.

Customizable Aesthetic Options

Resin-bound gravel surfaces provide over 46 colour options, enabling you to create a unique look that complements your space perfectly.

With a variety of shades available, you can keep up with current trends while adding your personal touch. Here are some options to consider:

- Natural stone colours – Create an organic appearance with earthy tones.

- Blended aggregates – Mix light and dark pebbles for a textured finish.

- Custom designs – Incorporate logos or patterns for a distinctive touch.

This design flexibility not only boosts visual appeal but also suits various architectural styles.

Diverse Surface Applications

As you explore various surface applications, you’ll find that resin-bound gravel surfaces offer remarkable versatility for both aesthetic and practical purposes.

These surfaces are ideal for a range of commercial settings, from parks to office complexes. Their adaptability allows for the creation of pathways, plazas, and cycle lanes that endure heavy foot traffic and changing weather while ensuring safety.

One of the key benefits of resin-bound surfaces is their fully permeable design, which aids in water management and supports sustainable urban drainage systems.

With options for custom aggregate sizes and colours, you can easily tailor the surface to enhance your surroundings without compromising on durability.

Positive Impact on Property Value and Image

Investing in resin-bound gravel surfaces can significantly enhance both the value and image of your property. Here are the key benefits:

- Increased Value: Installing a resin-bound driveway can raise your property value by 5-10%, with some cases seeing increases of up to 20%.

- Faster Sales: Properties featuring well-maintained resin surfaces tend to sell up to 15% quicker than those with traditional materials.

- Curb Appeal: The sleek and polished finish of resin surfaces greatly boosts aesthetics, making your home more attractive to potential buyers.

Frequently Asked Questions

How Long Does Installation of Resin-Bound Gravel Typically Take?

The installation time for resin-bound gravel varies depending on the size and complexity of the project. For smaller areas, such as a garden path or patio, it typically takes a day. Larger or more intricate projects may require several days. Proper planning can significantly improve your project timeline.

Can Resin-Bound Gravel Surfaces Be Repaired if Damaged?

Yes, resin-bound gravel surfaces can be repaired. Use effective techniques and follow maintenance tips to ensure they last. Regular checks and quick fixes for minor damage can save you from expensive repairs, helping to keep both the appearance and durability intact. For instance, if you notice small cracks or loose stones, addressing them early can prevent bigger issues down the line.

What Is the Ideal Base Material for Resin-Bound Gravel?

When it comes to resin-bound gravel, a robust base material such as MOT Type 3 aggregate is essential. Using the right installation techniques ensures durability, effective drainage, and stability, helping to avoid any future surface problems.

Is Resin-Bound Gravel Suitable for Residential Applications?

Yes, resin-bound gravel is a great choice for residential use. It requires minimal maintenance and looks appealing. Although installation costs can differ, its long-lasting durability and adherence to drainage regulations make it a wise investment for homeowners wanting quality surfaces. For example, it’s perfect for driveways or garden paths, providing a stylish finish that can withstand the UK weather.

How Does Temperature Affect the Curing Process of Resin-Bound Gravel?

Curing temperatures significantly affect the strength of resin-bound gravel. Installing in extreme cold or heat can cause thermal expansion, leading to defects that compromise durability. For the best results and longevity of your surface, stick to the recommended temperature range.

Conclusion

When choosing resin-bound gravel surfaces, you’re selecting durability and style, making a smart investment in your property. Imagine a robust landscape that endures both rain and shine, enhancing safety and value with minimal maintenance. This option combines practicality with visual appeal, creating a seamless finish that improves your commercial space. By opting for such surfaces, your property can stand out as a model of quality in a bustling urban setting.