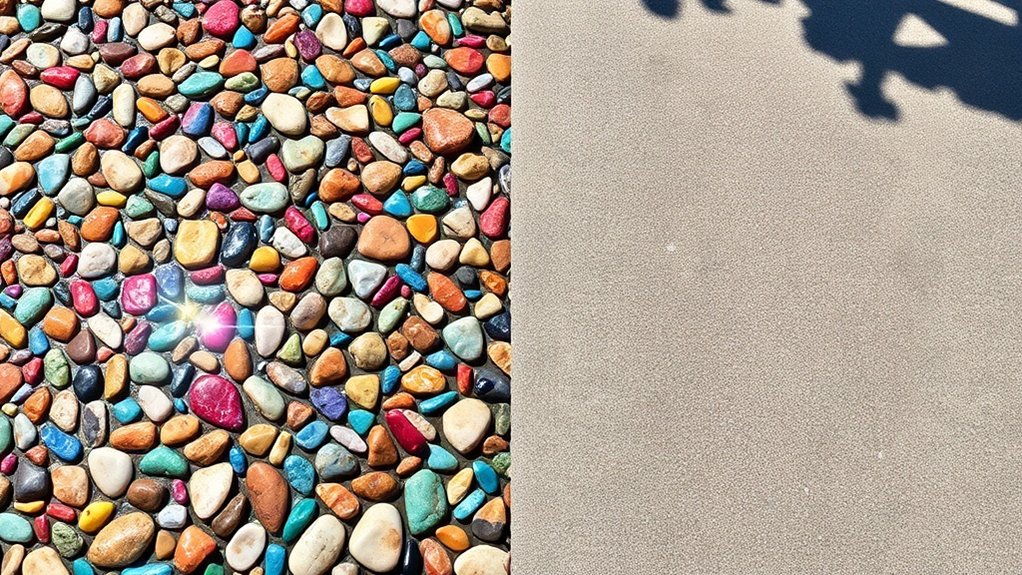

Resin-bound surfaces provide far more design flexibility compared to resin-bonded options. You’ll find an extensive selection of colours and aggregates, much like choosing paint swatches for your home. Mix different stones – from local gravels to striking granite chips – to create bespoke patterns. Resin-bonded surfaces typically come in standard colours with a uniform, coarser finish, rather like sandpaper. For creative freedom and unique designs, resin-bound is the clear winner.

Key Takeaways

Resin-bound surfaces trump resin-bonded when it comes to customisation options. Whilst resin-bonded surfaces typically come in single colours (think basic greys and browns), resin-bound offers a vast palette of colours and aggregate choices.

With resin-bound, you can create bespoke designs by mixing different stones – imagine combining warm golden pebbles with russet-coloured aggregates for your garden path. The smooth, consistent finish means patterns and borders look sharp and professional.

Resin-bonded surfaces, however, tend to be rather one-dimensional. Their scattered stone appearance often results in uneven patches, rather like a poorly laid gravel drive. The limited colour range and rough texture make it difficult to achieve anything beyond basic finishes.

The colour stability of resin-bound surfaces is particularly noteworthy for British weather – they won’t fade or discolour even after years of rain and sun exposure, making them a sound long-term investment for UK properties.

Understanding Resin-Bound and Resin-Bonded Systems

The key difference between resin-bound and resin-bonded systems lies in how they’re installed and perform.

Resin-bound surfaces mix the stones thoroughly with resin before laying, much like mixing ingredients for a cake. This creates a smooth, even surface that lets water drain through – ideal for British weather. The installer trowels the mixture carefully, ensuring it’s properly set. Resin bound surfaces are self-draining, which significantly reduces the risk of flooding in heavy rains. Additionally, *proper installation* is crucial for ensuring the best performance and longevity of the surface.

Resin-bonded surfaces work differently: resin goes down first, then loose stones are scattered on top, rather like throwing grit on an icy path. While this method is quicker and often cheaper, some stones may come loose over time, especially in high-traffic areas. The surface is also non-permeable, meaning rainwater won’t drain through.

Choose resin-bound for a premium, long-lasting finish that’s puddle-free, particularly suitable for driveways and patios.

Opt for resin-bonded if you need a quick, cost-effective solution and don’t mind occasional maintenance to replace loose stones.

Aesthetics and Color Options

Resin surfaces come in a range of colours and finishes to suit different design needs.

Resin-bound systems offer the widest choice, from popular greys and creams to striking reds – rather like choosing paint for your home. You can mix colours to create unique patterns, much like a pebble garden but with more control over the final look. This versatility allows for bespoke designs with limitless design possibilities. Additionally, the smooth, even finish of resin-bound surfaces enhances aesthetic appeal, making them a favored choice for homeowners looking to improve their property’s appearance.

Resin-bonded surfaces are more straightforward, usually coming in single colours with a rougher finish that’s less suited to intricate designs. Think of it as choosing between a detailed mosaic (resin-bound) or a simpler, uniform surface (resin-bonded).

While resin-bound surfaces tend to keep their colour well over time, resin-bonded options may need more upkeep to stay looking fresh, similar to how a painted fence needs occasional touching up.

Thickness and Aggregate Customization

The thickness and aggregate choices significantly impact resin surface performance and looks.

Resin-bound systems come in 15-25mm depths, offering better durability and proper stone distribution. You can tailor the thickness to suit your needs, whilst ensuring stones stay firmly embedded for a level finish. Additionally, the resin bound installation technique ensures that the surface can manage water effectively, preventing common issues associated with non-permeable surfaces.

Resin-bonded surfaces are thinner at roughly 5mm, with exposed stones that often create patchy textures and wear more quickly. This non-permeability of resin bonded surfaces can lead to issues with water drainage over time.

The advantage of resin-bound systems lies in mixing different stone types and sizes before laying. This gives you more control over the final look and practical benefits of your surface.

Think of it like making a proper Victoria sponge – the right depth of mixture and even distribution of ingredients make all the difference to the end result.

Application Suitability for Different Projects

Application Suitability Guide

Resin Bound

Perfect for UK driveways, garden paths and pool surrounds. Its smooth, permeable finish meets SuDS regulations, making it brilliant for our rainy climate.

The surface drains naturally, preventing puddles and flooding whilst looking smart.

Resin Bonded

Delivers excellent grip and mimics the look of loose gravel – ideal for public footpaths and driveways where safety comes first.

Popular across British housing estates and heritage properties wanting a traditional aggregate appearance.

Environmental Impact

Resin bound systems handle British weather brilliantly, allowing rainwater to drain through naturally.

Resin bonded surfaces need proper drainage planning to avoid water build-up, particularly important given our wet winters.

Cost Considerations and Installation Time

Cost and Installation Comparisons

Resin-bonded surfaces typically cost less and take less time to install than resin-bound alternatives. A typical 40m² driveway using resin-bonded surfacing might take one day to complete, whilst the same area with resin-bound could require two days or more.

Material costs vary significantly. Resin-bonded systems cost roughly £30-45 per m², whilst resin-bound surfaces range from £45-75 per m². Labour charges add approximately £20-30 per m² for either option.

The installation speed difference stems from the application method. Resin-bonded surfaces involve scattering aggregate onto pre-laid resin, much like spreading gravel.

Resin-bound requires thorough mixing of materials and careful trowelling, similar to laying concrete, hence the longer timeframe.

A practical tip: factor in an extra 10% to your budget for unexpected costs, such as sub-base repairs or additional materials.

Installation Time Differences

Installation Time Differences

Resin-bound and resin-bonded surfaces differ markedly in their installation times, affecting both costs and project planning:

- Resin-bound: Requires one to two days for completion. The careful mixing and trowelling process means you’ll wait 8 hours before walking on it and 48 hours before parking your car.

- Resin-bonded: Takes just one day, much like laying a standard driveway. You’ll be back to normal use more quickly than with resin-bound.

- Weather Impact: A rainy day will halt resin-bound work completely. Resin-bonded is more forgiving but still needs dry conditions – think typical British weather considerations.

Your choice between the two should match your timeframe and practical needs.

A busy shop entrance might benefit from resin-bonded’s quicker installation, whilst a premium home driveway might warrant the longer resin-bound process.

Cost Comparison Factors

Cost differences between resin-bound and resin-bonded surfaces are significant.

Resin-bound driveways cost £50-£100 per square metre, whilst resin-bonded surfaces run £15-£30 per square metre.

The higher price of resin-bound comes down to its more complex installation process – think laying a cake mixture rather than just scattering sprinkles.

However, it’s worth noting that resin-bound surfaces often prove more cost-effective over time, much like buying a quality pair of boots that last years versus cheap ones needing yearly replacement.

Resin-bonded surfaces are cheaper upfront but typically need more maintenance, including topping up loose stones and sorting drainage issues.

A bit like maintaining a gravel drive, you’ll need to factor in these ongoing costs.

When weighing up your options, consider how you’ll use the surface.

A busy family driveway might benefit from resin-bound’s durability, whilst a less-used garden path could make resin-bonded the smarter choice for your wallet.

Long-Term Value and Maintenance Requirements

Long-Term Value and Upkeep

Resin-bound and resin-bonded surfaces differ markedly in their lasting value and maintenance needs:

1. Durability: Resin-bound driveways and paths maintain their quality for 25+ years with minimal wear, much like a well-laid patio.

Resin-bonded surfaces tend to shed stones over time, rather like loose gravel driveways.

2. Regular Care: A quick sweep and occasional pressure wash keep resin-bound surfaces pristine.

Resin-bonded requires more attention – similar to maintaining a gravelled area – with regular checks for loose stones and water puddles.

3. Weather Resistance: Resin-bound’s permeable nature handles British weather brilliantly, cutting long-term costs.

Resin-bonded can struggle with drainage, particularly during heavy rainfall, leading to more frequent repairs.

These differences often make resin-bound the smarter long-term investment for UK homeowners, despite higher initial costs.

Frequently Asked Questions

Which System Is More Environmentally Friendly: Resin-Bound or Resin-Bonded?

Resin-bound surfaces stand out as the greener choice compared to resin-bonded systems. The key advantage lies in their permeable nature – rainwater simply filters through rather than running off into drains. This natural drainage helps prevent localised flooding, much like a garden would handle rainfall. The system also uses sustainable materials and creates small spaces between stones where plants can grow, supporting local wildlife. In contrast, resin-bonded surfaces are sealed, causing water to pool or run off, which can worsen flooding and offers little ecological value.

How Do Climate Conditions Affect Resin-Bound and Resin-Bonded Installations?

Climate plays a vital role in how resin driveways perform. Resin-bonded surfaces can crack when temperatures shift dramatically, particularly during British winters. In contrast, resin-bound systems offer more flexibility, handling our weather changes better – from summer heat to winter frost. Think of it like comparing a rigid plastic container to a rubber one; the more flexible option tends to last longer and needs less upkeep.

Can Both Systems Be Repaired if Damaged?

Both systems are repairable through specific methods. To prevent damage, ensure regular maintenance, proper surface prep and routine checks. Catching issues early – like small cracks or loose stones – means simpler fixes and helps both resin-bound and resin-bonded surfaces last longer. Think of it like maintaining your car: regular servicing prevents major problems down the line.

What Is the Lifespan Difference Between Resin-Bound and Resin-Bonded Surfaces?

Resin-bound surfaces typically last 15-25 years, whilst resin-bonded surfaces manage just 5-15 years. Think of it like comparing a properly sealed driveway to a loose gravel one – the bound system, with its thoroughly mixed materials, simply holds up better over time. This makes bound surfaces ideal for busy areas like shopping centre car parks or residential driveways where you’d rather not faff about with frequent repairs.

Are There Any Specific Cleaning Products Recommended for Each System?

Resin-bound surfaces need pH-neutral cleaners or mild detergents like washing-up liquid diluted in warm water. For resin-bonded surfaces, a gentle brush with soft bristles and standard household cleaner works well. Just avoid harsh chemicals on either surface – they’ll do more harm than good. Most UK DIY shops stock suitable cleaners, with brands like Jeyes or Dettol offering appropriate options.

Conclusion

In summary, resin-bound surfaces offer significantly more customisation options than their bonded counterparts. You’ll find a broader selection of colours, depths and aggregate sizes to choose from, making it easier to achieve your desired look. When planning your project, whether for a driveway or garden path, the versatility of resin-bound systems makes them the more adaptable choice for most UK properties.