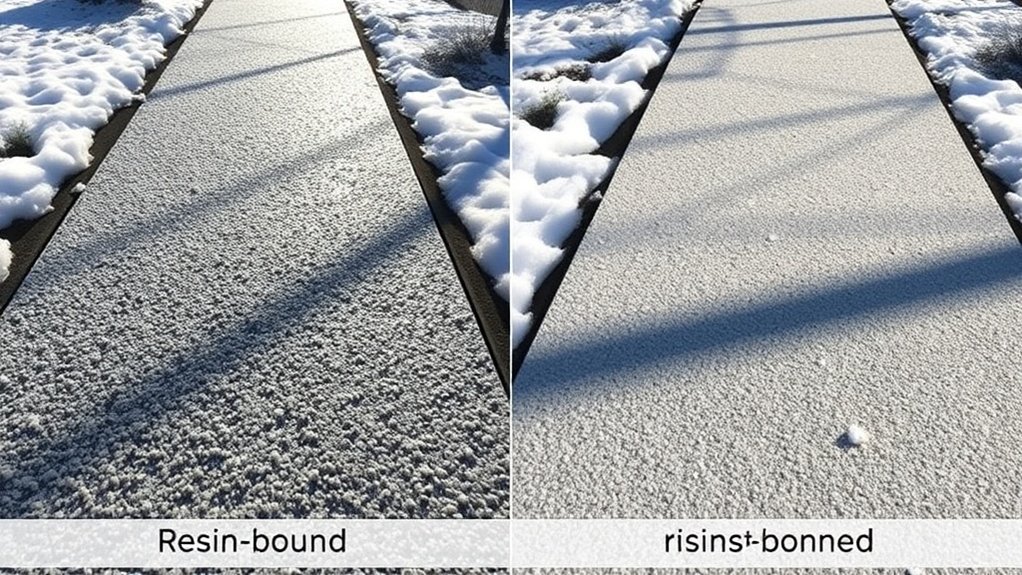

When it comes to cold weather performance, resin-bound surfaces are superior to resin-bonded options. Their high permeability allows for efficient water drainage, which helps prevent ice from forming. Moreover, resin-bound systems are less likely to crack during freeze-thaw cycles, thanks to their fully encapsulated aggregates, providing enhanced durability. In contrast, resin-bonded surfaces can be more susceptible to flaking and losing aggregates. It’s crucial to choose the right surface for longevity and safety in colder climates, so take the time to understand these differences for a well-informed decision.

Key Takeaways

- Resin-bound surfaces are highly permeable, allowing effective drainage and preventing ice build-up, unlike non-permeable resin-bonded surfaces.

- The textured finish of resin-bound surfaces offers better traction in cold weather, enhancing safety on icy paths.

- Resin-bound systems are resistant to cracking during freeze-thaw cycles, whereas resin-bonded surfaces are more likely to flake and suffer from water damage.

- With a lifespan of 20-30 years, resin-bound surfaces are more durable in colder climates compared to resin-bonded surfaces, which typically last only 5-10 years.

- Proper installation and substrate preparation are essential for resin-bound surfaces, particularly in cold weather, to ensure they perform optimally.

Understanding Resin Bound and Resin Bonded Surfaces

When choosing outdoor surfaces, it’s important to know the differences between resin-bound and resin-bonded systems, particularly in colder weather.

Resin-bound surfaces combine aggregates and resin, forming a durable, frost-resistant layer that can endure freeze-thaw cycles. This type of surface can last up to 30 years, making it a great choice for long-term use. Additionally, resin-bound surfaces are highly permeable, allowing water to pass through and support sustainable drainage, which is beneficial during winter thaw periods. The porous design of resin-bound surfaces helps prevent ice patches from forming.

On the other hand, resin-bonded systems consist of a resin base covered with loose aggregates, typically lasting 5-10 years. They’re more susceptible to temperature changes.

Both systems can handle temperatures from -20°C to +60°C, but resin-bound surfaces are generally tougher and require careful installation to ensure proper curing and performance in colder conditions.

Permeability and Ice Management

Both resin-bound and resin-bonded surfaces have their specific uses, but their permeability plays a crucial role in managing ice during colder months.

Resin-bound surfaces are highly permeable, allowing water to drain away effectively. This prevents puddles from forming and freezing, which can create dangerous conditions. Their porous structure helps reduce ice accumulation, offering better traction when the temperatures drop. Additionally, their durability ensures they can withstand extreme cold temperatures without cracking, and they also support Sustainable Urban Drainage Systems that enhance their effectiveness during winter.

In contrast, resin-bonded surfaces are non-permeable and require additional drainage solutions for runoff. Although they provide slip resistance, they aren’t designed for vehicles and may not be as safe.

Therefore, for effective ice management and safety in cold weather, resin-bound surfaces are the superior choice.

Durability in Freeze-Thaw Cycles

Understanding the durability of resin-bound and resin-bonded surfaces in freeze-thaw cycles is crucial when choosing materials for your project.

Resin-bound surfaces are more resilient because their aggregates are fully encapsulated, which helps maintain surface integrity during temperature changes. This design significantly reduces the risk of cracking and crumbling, with a lifespan of 20 to 30 years. Additionally, installation should occur in dry periods to ensure optimal curing and bonding, further enhancing durability. Furthermore, resin-bound surfaces typically come with a 10-year guarantee, ensuring long-term performance that justifies the initial investment.

On the other hand, resin-bonded surfaces have a thinner resin layer, making them more susceptible to flaking and cracking, often resulting in a lifespan of only 5 to 10 years. The weaker bond in resin-bonded systems allows water to seep in, which accelerates damage.

For projects in areas prone to freeze-thaw conditions, resin-bound materials are the better option, offering greater durability and less maintenance over time.

Installation Conditions and Curing in Cold Weather

When installing resin-bound and resin-bonded systems in cold weather, it’s crucial to know the right temperature range.

Ideally, resin-bound systems should be installed when temperatures are between 5°C and 25°C.

In colder conditions, curing times can be significantly extended. For example, if you’re working on a driveway in winter, be prepared for longer waiting times before the surface is fully set.

Understanding these factors helps you tackle installation challenges effectively and ensures proper curing.

Optimal Temperature Range

To ensure proper installation and curing of resin systems in cold weather, it’s essential to keep temperatures within 5°C to 25°C. Adhering to installation guidelines is key to achieving optimal resin temperature during application. Here’s a quick reference on how temperature affects the resin:

| Temperature Range | Effect on Resin | Installation Considerations |

|---|---|---|

| Below 5°C | Curing is delayed | Higher risk of moisture |

| 5°C – 25°C | Ideal curing | Best for bonding |

| Above 25°C | Curing speeds up | Shortened pot-life |

| Extreme Conditions | Increased risk of problems | Professional help advised |

It’s crucial to monitor ground and tarmac temperatures, as they can be higher than air temperatures. Using temperature probes can help ensure accuracy and reduce risks from extreme heat or cold during installation.

Curing Time Variations

As temperatures drop, curing time for resin-bound and resin-bonded systems becomes crucial for successful installation.

In colder weather, resin-bound systems often need over 48 hours to fully cure, while resin-bonded systems cure more quickly due to their thinner resin layer.

Low temperatures, especially below 5°C, significantly slow the chemical reactions required for curing. This can lead to longer curing times, increasing the risk of moisture damage and surface flaws.

Using catalysts can speed up curing in cold conditions, but you’ll need more as temperatures decrease.

Therefore, careful planning and monitoring of installation conditions are essential to ensure the best performance and durability of both systems during the winter months.

Surface Texture and Traction During Cold Weather

How do surface texture and traction impact safety in cold weather? The surface finish of resin-bound systems is crucial for grip, particularly in icy conditions. Their textured, slightly rough surfaces enhance traction, effectively reducing the risk of slips.

In contrast, resin-bonded surfaces may start off rough but can suffer from aggregate migration over time, which diminishes their grip.

Moreover, resin-bound surfaces are porous, allowing melted snow to drain away and reducing ice formation. On the other hand, resin-bonded surfaces retain moisture, increasing the likelihood of slipperiness.

The honeycomb structure of resin-bound systems can accommodate ice expansion without cracking, which helps maintain traction during freeze-thaw cycles.

Maintenance and Longevity Under Cold Conditions

When considering resin-bound and resin-bonded surfaces, their maintenance and durability in cold conditions vary significantly.

- Resin-bound surfaces need minimal winter upkeep, mainly just snow clearance.

- Ice can be treated with non-corrosive de-icers without causing harm.

- In terms of longevity, resin-bound systems can last up to 30 years, whereas resin-bonded surfaces may only endure 5 to 10 years in colder climates.

- It’s crucial to carry out regular inspections on resin-bonded surfaces, particularly after freeze-thaw cycles.

Structural and Base Considerations for Cold Weather Performance

To ensure optimal performance of resin-bound and resin-bonded surfaces in cold weather, it’s crucial to understand substrate compatibility and proper preparation.

Resin-bound systems need a solid, stable base—such as concrete or asphalt—to withstand harsh conditions. On the other hand, resin-bonded surfaces can be applied to various substrates, but they must be dry and clean to prevent adhesion problems, particularly in freezing temperatures.

Frost protection measures are vital; insulating the base helps prevent frost heave, which can cause surface deformation.

Additionally, keep an eye on ground temperatures, as conditions below 10°C can slow down curing and weaken the bond. Proper drainage is also important for resin-bound surfaces to avoid water accumulation, which can worsen freeze-thaw damage.

Comparing Lifespan and Performance in Cold Climates

When evaluating lifespan and performance in cold climates, resin-bound surfaces clearly outperform resin-bonded options.

Here are the main reasons for their superior longevity:

- Resin-bound surfaces can last up to 30 years, whereas resin-bonded typically last between 5 and 10 years.

- They’re resistant to cracking during freeze-thaw cycles, which makes them more durable in harsh winter conditions.

- Their porous design facilitates effective drainage, reducing ice build-up and potential hazards.

- Resin-bound surfaces require minimal maintenance, which helps lessen environmental impact over time.

On the other hand, resin-bonded surfaces are prone to flaking and aggregate loss, significantly shortening their lifespan.

For lasting performance and reduced environmental strain, resin-bound systems are the more dependable choice in cold climates.

Recommendations for Choosing the Right Option

When deciding between resin-bound and resin-bonded surfaces, think about your local climate and maintenance needs.

Resin-bound systems are generally better for colder conditions as they allow water to drain away and are more flexible.

On the other hand, resin-bonded surfaces may require more upkeep over time.

Assessing these aspects will help you choose the option that best suits your safety and durability requirements.

Consider Climate Conditions

Choosing the right surfacing option for cold weather is crucial to ensure safety and longevity. Here are the key factors to consider:

- Permeability: Resin-bound surfaces help prevent ice build-up by allowing water to drain away, reducing slipping hazards.

- Durability: These systems are more resilient against freeze-thaw cycles, which is important for longevity in harsh conditions.

- Installation Conditions: Both systems need temperatures above 5°C for proper curing; resin-bound surfaces may take longer to set.

- Slip Resistance: Resin-bound surfaces offer better safety by reducing dangerous ice patches, whereas resin-bonded surfaces can become slippery when ice forms.

Evaluate Maintenance Requirements

Understanding the maintenance needs of resin-bound and resin-bonded surfaces is crucial for your winter requirements.

Resin-bound driveways are low maintenance, needing just the occasional sweep and wash. On the other hand, resin-bonded surfaces require more frequent cleaning due to the risk of stone migration, which can compromise the surface’s integrity.

Both types benefit from regular debris removal to prevent staining.

Resin-bound surfaces resist moss and algae growth, while resin-bonded surfaces may develop bald patches over time, requiring occasional reapplication.

Annual inspections for surface integrity are important for both options.

If you prefer lower cleaning frequency and better durability, go for resin-bound. However, if you opt for resin-bonded, be prepared for more upkeep and potential repairs down the line.

Frequently Asked Questions

Can Resin Bound or Bonded Surfaces Be Repaired if Damaged?

Yes, resin-bound or bonded surfaces can be repaired if damaged. Start by assessing the damage to determine how extensive it is. Depending on the situation, you can opt for localized patching or, if necessary, full resurfacing. For instance, if there’s a small crack, a patch might suffice, but larger areas may require a complete redo.

How Do Temperature Fluctuations Affect Resin Surfaces?

Temperature fluctuations can significantly affect resin surfaces. For example, a poorly installed resin-bonded driveway may crack under stress, undermining its durability. In contrast, resin-bound systems are more resilient to temperature changes, maintaining their structural integrity even through freeze-thaw cycles. This makes them a better choice for areas with varying weather conditions.

Is There a Significant Cost Difference Between the Two Options?

Yes, there is a notable cost difference. Resin-bound surfaces typically come with higher initial costs but offer greater long-term durability. On the other hand, resin-bonded surfaces are more budget-friendly upfront but may lead to higher maintenance costs over time.

What Colors and Finishes Are Available for Each Surface Type?

You’ll find a variety of colour options and finishes for both resin-bound and resin-bonded surfaces. Resin-bound surfaces typically provide a broader range of colours, making them ideal for personalised designs. In contrast, resin-bonded surfaces focus on textured finishes, which enhance grip and offer a visually appealing aesthetic.

Are There Specific Brands Known for Better Cold Weather Performance?

You might assume all brands perform the same in cold weather, but RonaDeck and Ace Resin Surfacing are known for their superior cold-weather performance. Their advanced materials provide exceptional durability, making them highly recommended for winter resilience.

Conclusion

In summary, resin-bound surfaces generally perform better in cold weather compared to resin-bonded ones, thanks to their higher permeability and better resistance to freeze-thaw cycles. While the initial investment may be a concern, the long-term advantages, such as lower maintenance costs and a longer lifespan, make resin-bound systems a wise choice. Opting for the right surface can enhance safety and performance during harsh winter months, ensuring a dependable solution for your needs. Consider these factors carefully to achieve lasting results.