Leading UK resin-bound gravel manufacturers include DALTEX, who back their products with a 15-year guarantee. GeoBondX and Resin Bound Solutions specialise in environmentally conscious mixes, whilst offering bespoke blends. These suppliers deliver both durability and style, with various colours and finishes to match British gardens and driveways. The robust UK delivery networks ensure smooth, timely installations nationwide.

Key Takeaways

Leading UK Manufacturers Shaping Resin-Bound Gravel Solutions

DALTEX commands the British market with comprehensive resin-bound gravel options and backs their products with a solid 15-year guarantee.

GCL Products’ speciality lies in kiln-dried aggregates – crucial components that ensure your resin sets properly and lasts longer.

For unique projects, Resin Bound Solutions crafts custom aggregate blends, perfect for anything from garden paths to commercial driveways.

GeoBondX champions environmentally sound permeable surfaces, ideal for both home gardens and business parks whilst meeting UK drainage requirements.

Our domestic manufacturers emphasise sustainability, sourcing local stone and delivering varied colours and textures to suit British architecture and landscaping needs.

Overview of Resin-Bound Gravel Technology

Resin-bound gravel offers a practical surfacing solution that merges natural stone with modern technology. By mixing aggregates with clear resin, you get a sturdy, permeable surface that meets UK drainage regulations. This type of gravel is also eco-friendly, compliant with SUDS regulations, which further enhances its appeal for sustainable landscaping. Additionally, the mixture is designed to withstand a range of conditions due to its chemical bonding, ensuring long-lasting performance.

The installation requires a solid base of concrete or asphalt, followed by thorough mixing in a forced-action mixer – much like preparing a large batch of particularly tough cake mix. Once mixed, workers spread and trowel the material to create a smooth finish.

The surface needs little upkeep, keeps weeds at bay, and helps prevent flooding by allowing rainwater to drain naturally through the surface. It’s particularly useful for British driveways, garden paths and patios, where our wet weather demands effective drainage solutions.

Leading Manufacturers in Resin-Bound Solutions

The UK’s resin-bound surfacing market is driven by several key manufacturers. DALTEX leads the pack, offering Britain’s most extensive range of resin-bound gravel, complete with a 15-year guarantee. Additionally, DALTEX is the only manufacturer of DALTEX aggregates and gravels in the country, ensuring their unique offerings stand out in the market. Resin-bound surfaces are becoming increasingly popular due to their exceptional durability and longevity, making them a preferred choice for many homeowners.

GCL Products specialises in kiln-dried aggregates that ensure proper resin curing, whilst Resin Bound Solutions crafts bespoke aggregate mixes for specific project needs. GeoBondX has carved its niche with eco-friendly permeable pavements, popular for both domestic driveways and commercial developments.

These manufacturers maintain strong supplier partnerships across the UK, ensuring reliable stock and distribution. Most offer next-day delivery and bulk purchase options, serving everything from major construction projects to individual homeowners. Their combined presence has helped establish resin-bound surfaces as a trusted choice for British landscaping and construction needs.

Innovative Product Offerings in the Market

The resin-bound gravel sector is seeing rapid growth in advanced products that boost both function and looks.

British manufacturers now offer specialised resin systems like GeoBondX and PermaBound, built for long-term wear and striking appearance. Many firms prioritize green practices by using local stones and aggregates, cutting transport emissions, and contributing to the circular economy.

You can choose from plenty of textures and colours to suit your project, whether it’s a smart driveway or garden path. Modern solutions like CANA Pave™ work with reinforcement grids, giving better support and meeting UK building standards.

Quick-setting formulas and custom mixes mean installers can work more efficiently, whilst delivering top-quality surfaces that last. Innovations like GeoBondX’s highly durable products are raising the bar for resin-bound surfacing across Britain.

Environmental Benefits of Permeable Resin-Bound Surfaces

Permeable resin-bound gravel tackles common British drainage issues whilst delivering key environmental benefits.

Unlike traditional paving, these surfaces allow rainwater to filter through naturally, reducing puddles and flood risks – particularly helpful during our wet winters.

The system works brilliantly for UK properties, helping replenish groundwater levels and meeting local SUDS requirements.

Think of it as a giant filter: water seeps through the surface, trapping pollutants before they reach our streams and rivers. This helps protect local wildlife and keeps our waterways cleaner.

These surfaces also help cool urban areas during summer heatwaves, unlike tarmac or concrete which trap heat.

For homeowners and developers, permeable resin-bound gravel offers a practical, environmentally sound choice that looks smart whilst helping tackle common UK drainage challenges.

Aggregate Variety and Customization Options

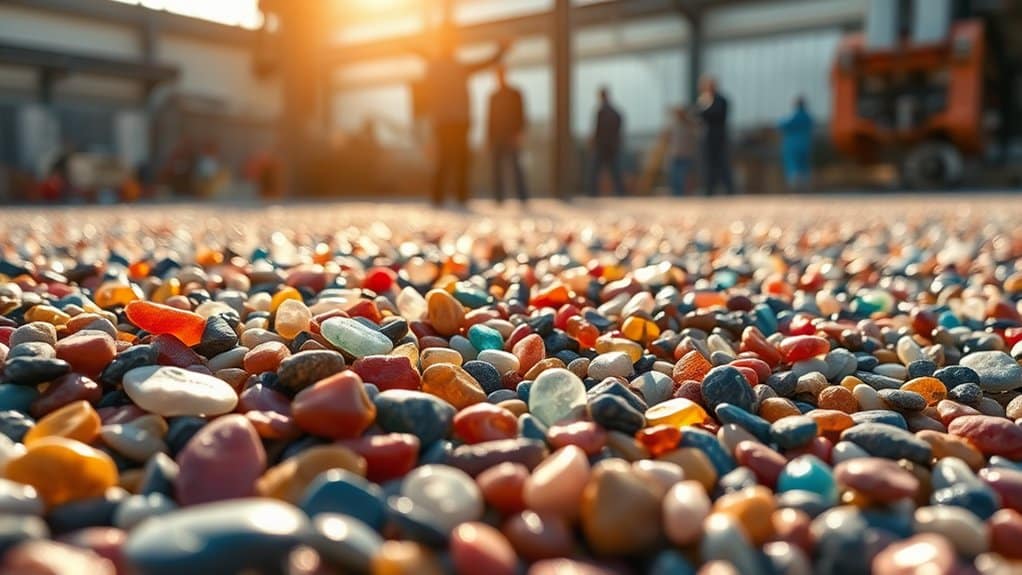

The breadth of aggregates and customisation choices for resin-bound gravel makes each project unique.

Natural aggregates like quartz and granite offer proven durability, whilst decorative additions such as glass chips create eye-catching finishes.

The wide range of colours and textures means you’ll find the right match for your space, whether it’s a classic driveway or modern garden path.

Aggregate Types Overview

Understanding aggregate types is vital for construction and landscaping works across the UK. Natural aggregates, such as sand and gravel, come straight from the ground, whilst manufactured aggregates are produced from industrial by-products.

Recycled options, like crushed concrete from demolition sites, offer a sustainable choice that’s gaining popularity amongst British builders.

Primary aggregates are quarried directly from sites across Britain, and secondary aggregates come from reclaimed materials. Each type brings different properties – from the fine grains of building sand to chunky crushed stone for motorway foundations.

These characteristics directly affect how they perform in common applications, such as garden drainage, concrete mixing, or road surfacing.

For best results on any project, whether it’s a garden patio in Cornwall or a commercial build in Glasgow, choosing the right aggregate makes all the difference.

The growing focus on sustainability means recycled options are particularly worth considering for many UK construction projects.

Custom Blends Benefits

Custom Blends Benefits

Custom blends of resin-bound gravel offer exceptional adaptability for both visual appeal and practical use across UK properties. The right blend creates surfaces perfectly suited to Britain’s varied climate and architectural styles.

Key benefits:

- Precise Control: Adjust stone mixtures to match local building materials or achieve specific grip levels – particularly useful for steep driveways in rainy conditions.

- Unique Patterns: Design distinctive layouts, from classic Yorkshire stone effects to modern geometric patterns.

- Surface Performance: Select larger aggregates for high-traffic areas like car parks, or finer blends for garden pathways.

- Environmental Adaptation: Choose mixes that handle British weather effectively – from frost-resistant blends for Scottish winters to permeable solutions for flood-prone regions.

Color and Texture Options

Resin-bound gravel comes in over 40 colours, offering plenty of choices to suit any outdoor space. From warm yellows to modern silvers, each shade creates a different feel and mood. The texture can be fine or coarse, depending on your preference for underfoot comfort and visual appeal.

| Colour Options | Texture Types | Popular Blends |

|---|---|---|

| Warm Tones | Smooth | Oyster Pearl |

| Cool Tones | Coarse | Porto Fino |

| Monochrome Blends | Mixed Textures | Purity |

Mix and match colours and textures to create a practical, attractive surface that works for your property. Common choices include Oyster Pearl for driveways and Porto Fino for garden paths, whilst Purity offers a clean, contemporary look for modern homes.

Market Trends and Supplier Logistics

Modern supply chain logistics are transforming the UK resin-bound gravel industry. Faster shipping networks and comprehensive product packages allow builders and contractors to better manage their projects.

Smart logistics solutions, such as next-day delivery and real-time tracking, help meet tight construction schedules. These improvements mean less warehouse space needed and reduced project delays.

For example, suppliers now offer pre-mixed colour batches and coordinated delivery slots, particularly useful for large housing developments or council projects.

Staying current with these advances gives firms a clear market advantage, especially during peak building seasons.

Supply Chain Innovations

Supply Chain Innovations

The construction industry’s shift towards sustainability has sparked major changes in supply chain and logistics. Suppliers now focus on making their operations more resilient and efficient:

- EcoBatcher System: An on-site resin mixing solution that cuts plastic waste and ensures exact measurements.

- SUDS Integration: Building Sustainable Urban Drainage Systems into products to tackle flooding risks whilst improving performance.

- National Distribution Networks: British firms like Resin Rock are building country-wide networks to ensure reliable delivery of resin-bound materials.

- Product Range: Multiple aggregate sizes and colours now available to suit any project, from garden paths to car parks.

These improvements make sustainable building materials both more environmentally friendly and easier to source across the UK, whilst keeping costs manageable for contractors and developers.

Delivery Service Enhancements

Suppliers across the UK are upgrading their delivery systems to keep pace with tight construction schedules.

Smart route planning helps avoid holdups and ensures resin-bound gravel arrives when needed. You can track your deliveries in real time, letting you spot any issues before they affect your timeline.

Better coordination between manufacturers and building teams means more precise delivery slots that fit your schedule.

Purpose-built vehicles and handling equipment protect your materials during transport. Many firms now use eco-friendly delivery methods, cutting both costs and carbon footprint.

These changes mean faster project completion and a more reliable service from your supplier.

Whether you’re working on a small driveway in Manchester or a large commercial project in London, you’ll notice the difference in delivery efficiency.

Integrated Product Solutions

The resin-bound gravel sector is shifting towards complete product packages that blend visual appeal with practicality.

More suppliers now offer comprehensive solutions that work together seamlessly:

- Custom blends incorporate local stone and aggregate, helping driveways and paths match the surrounding area.

- Ready-to-use kits pack everything needed – aggregates, resin and tools – making DIY installation straightforward.

- Anti-slip additives like GRIPDUST ensure surfaces meet British safety standards, particularly vital for public spaces.

- Sustainable options feature recycled materials and polypropylene honeycomb bases, reducing environmental impact.

These integrated solutions are particularly valuable for British weather conditions, where durability and drainage matter as much as looks.

Versatile Applications of Resin-Bound Gravel

Resin-bound gravel stands as a top choice for numerous applications across the UK, combining lasting strength with smart looks.

It works brilliantly for home driveways, garden paths and patios, whilst requiring minimal upkeep. For business properties, it proves particularly effective in car parks and walkways, delivering a robust surface that ticks environmental boxes.

The permeable nature helps manage rainfall, especially useful in Britain’s wet climate. Installation is straightforward, often possible directly over existing surfaces.

Being slip-resistant and UV stable, it maintains both safety and appearance year-round. From domestic gardens to commercial spaces, resin-bound gravel delivers practical, attractive results for virtually any project.

Contractor Support and Training Initiatives

Investing in resin-bound gravel projects? Proper contractor support and training make all the difference to your success.

Strong development programmes boost both your technical knowledge and business growth.

Key advantages:

- Training Certifications: Earn recognised UK qualifications to boost your market credibility and meet British standards.

- Practical Skill Development: Master techniques through hands-on practice, from small garden paths to large commercial projects.

- Business Development Support: Get trade discounts, regional market data and proven marketing tools to expand your client base.

- Contractor Networking: Build valuable connections with fellow UK installers during training sessions and industry meetups.

These elements create a solid foundation for any resin-bound contractor looking to establish themselves in the British market.

Future Innovations in Resin-Bound Products

Future developments in resin-bound surfacing are set to transform the UK paving industry. New UV-resistant resins will better withstand our British weather, keeping driveways and paths looking fresh for longer.

Improved anti-slip technology will prove particularly valuable during wet winters, whilst advanced porous systems like Solepave will help manage our frequent rainfall more effectively.

Expect to see more colour options and natural stone choices, perfect for matching traditional British architecture or creating modern designs.

Manufacturers are developing greener formulations with lower emissions, addressing growing environmental concerns. These products will offer better resistance to frost and temperature changes – crucial for our climate.

The latest bonding techniques mean stronger, longer-lasting surfaces, reducing maintenance needs and offering better value for money.

Whether for domestic driveways or commercial spaces, these innovations will deliver both practical benefits and kerb appeal.

Frequently Asked Questions

What Are the Installation Requirements for Resin-Bound Gravel Surfaces?

Proper resin-bound gravel installation demands careful surface prep, specialist tools and precise resin-to-aggregate mixing ratios. Sort any drainage concerns beforehand and ensure correct depth measurements – typically 18mm for paths and 20-25mm for driveways. A solid base of concrete or tarmac is essential for a long-lasting finish that won’t crack or split during British weather changes.

How Long Does Resin-Bound Gravel Last Before Needing Repairs?

Resin-bound gravel, when properly installed and maintained, lasts between 15-25 years in British weather conditions. Much like a garden patio or driveway, it benefits from simple upkeep every 3-5 years to address minor wear and tear. Regular maintenance, such as sweeping and occasional pressure washing, helps maintain its appearance and structural integrity throughout its lifespan.

Can Resin-Bound Gravel Be Removed and Replaced Easily?

Removing resin-bound gravel is quite tricky and typically requires specialist tools and expertise. Whilst localised repairs are possible for damaged patches, it’s rather like trying to patch a carpet – getting a perfect match can be challenging. Professional removal ensures you won’t damage the base layer underneath, which is crucial for any new surfacing you might install.

Are There Specific Climate Considerations for Resin-Bound Installations?

Climate plays a crucial role in resin-bound installations across the UK. The ideal temperature range is 5-25°C – typical British weather is usually spot-on for this. Avoid installing during frosty conditions or intense summer heat, as these extremes affect how the resin cures. Rain forecast? Best to postpone, as moisture can compromise the finish. The ground temperature matters too – if your patio’s been in direct sun all day, wait until it cools down before starting work. Proper planning around our changeable British weather ensures your resin surface sets correctly and lasts longer.

What Maintenance Is Required for Resin-Bound Gravel Surfaces?

Regular sweeping and occasional pressure washing keep resin-bound gravel surfaces in top condition. A stiff brush removes leaves and debris, whilst an annual deep clean with a pressure washer prevents moss build-up. Much like caring for a patio, use gentle, pH-neutral cleaners to protect the resin binding. For stubborn stains, specialist solutions from UK suppliers work best – just avoid harsh chemicals that might damage the surface.

Conclusion

The resin-bound gravel sector is transforming modern British landscaping with practical, attractive solutions. Leading manufacturers now combine cutting-edge technology with eco-friendly methods, delivering surfaces that work brilliantly for both domestic gardens and commercial spaces. Much like choosing the right paint for your home, selecting quality resin-bound materials makes all the difference to the finished result. With solid technical support and plenty of design options, these systems offer landscapers and homeowners a durable, low-maintenance choice for driveways, paths and patios across the UK.