Resin-bound gravel creates a smooth, hardwearing surface with plenty of colour choices, perfect for modern British gardens and driveways. It drains naturally and lasts over 30 years with little fuss. Resin-bonded gravel, on the other hand, has a rougher finish and needs more looking after, typically lasting 10-15 years. Being waterproof, it requires proper drainage planning – much like a standard concrete driveway. Choose between the two based on your budget, preferred look and practical needs.

Key Takeaways

Resin-bound gravel gives you a smoother finish and lasts over 30 years, whilst resin-bonded gravel typically needs replacing after 10-15 years.

The depth difference is significant – resin-bound needs 15-24mm, but resin-bonded only requires 4mm (about the thickness of a pound coin).

A major advantage of resin-bound gravel is its excellent drainage. Rain water seeps straight through, preventing puddles and flooding – much like a sponge. Resin-bonded, however, is waterproof and needs proper drainage channels.

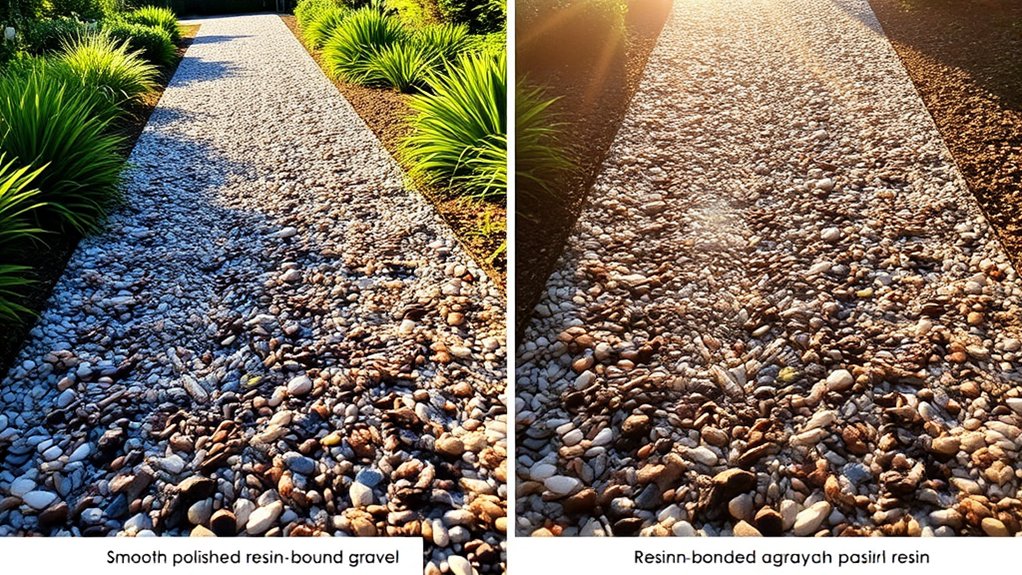

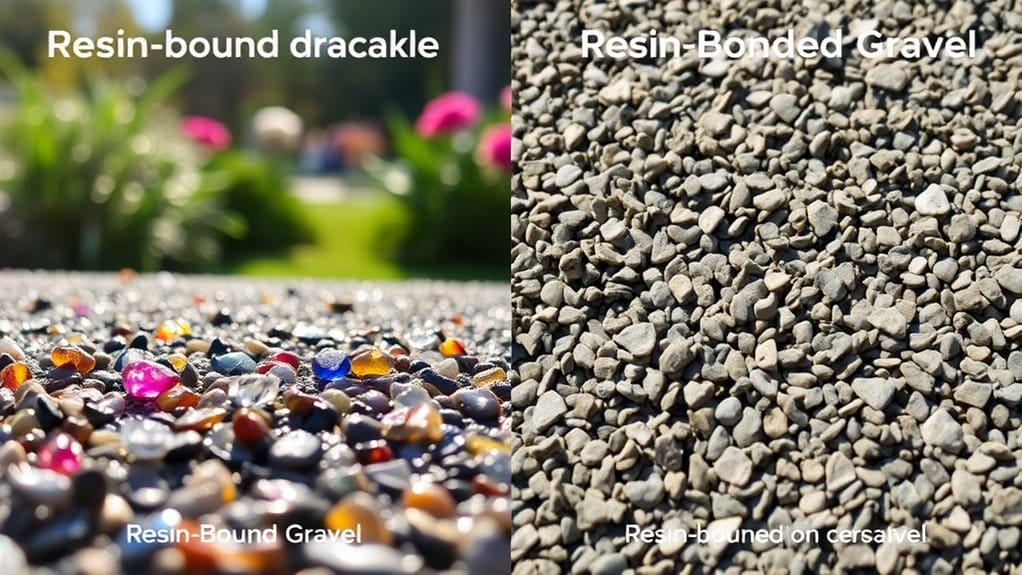

Style-wise, resin-bound offers modern, sleek finishes perfect for contemporary homes and gardens. Think polished pebbles rather than loose gravel. Resin-bonded provides a more traditional, textured look, similar to a regular gravel driveway.

Whilst resin-bound costs more upfront, it's more cost-effective long-term. You'll spend less time and money on maintenance compared to resin-bonded surfaces, which often need regular attention to stay looking sharp.

Installation Methods

Proper installation of resin-bound and resin-bonded gravel requires different approaches.

Both systems need thorough surface preparation – clean the area and fix any potholes or cracks to ensure a level base.

For resin-bound installations, you'll need trowels and rollers to achieve a smooth finish. Ensure existing surface is clean and debris-free is essential for a successful installation. The resin-bonded method is generally quicker due to its simpler layering process and proper mixing ratios to achieve the ideal material consistency.

With resin-bonded gravel, simply spread the resin onto your prepared surface before scattering the stones.

The weather matters – work when it's above 10°C for best results.

Resin-bound systems need a 15-24mm depth, whilst resin-bonded only needs about 4mm.

Getting the right mix ratio between resin and aggregate is crucial – think of it like following a recipe where the wrong measurements could spoil the end result.

Durability and Maintenance

Resin-bound gravel proves highly durable, typically lasting over 30 years with basic maintenance. Its porous nature naturally prevents weed growth and handles British weather well, letting rainwater drain efficiently. Additionally, the high-quality resins used in resin-bound gravel contribute significantly to its longevity. Resin-bound surfaces excel in preventing weed growth, reducing the need for herbicides and manual weeding. Whilst resin-bonded gravel offers an attractive finish, it needs more frequent upkeep to stay in top condition, much like a block-paved driveway would require regular sweeping and cleaning.

Long-lasting Performance

Resin-bound and resin-bonded gravel systems offer attractive surfacing choices, but their durability differs significantly.

Resin-bound gravel lasts over 25 years, whilst resin-bonded typically manages just 10 to 15 years. Think of resin-bound as a robust jumper with tightly woven fibres – the stones are fully wrapped in resin, making them highly stable and resistant to movement. Additionally, resin acts as a bonding agent for the aggregate in resin-bound gravel, which contributes to its long-lasting performance. Proper installation and preparation are crucial factors that ensure this durability.

You'll find resin-bound surfaces cope brilliantly with heavy foot traffic, much like shopping centre floors, and they handle British weather extremes without cracking. The surface allows rainwater to drain through naturally, preventing puddles from forming.

Resin-bonded gravel, however, tends to come loose over time, rather like scattered gravel on a driveway, making it less dependable for long-term use.

Maintenance Requirements

Regular maintenance of resin-bound gravel is straightforward and cost-effective.

For daily cleaning, standard household cleaner works perfectly well. Give the surface a thorough pressure wash once or twice a year using a fan nozzle to protect the material. A quick sweep now and then keeps debris at bay and reduces the need for deep cleaning.

Stubborn marks might need specialist cleaners, which can be pricier.

In winter, avoid using rock salt for ice and snow removal, as it can damage the surface. Instead, opt for gentler methods like brushing or approved de-icing products.

Proper care significantly extends the life of resin-bound surfaces, making them a solid investment for British homeowners.

The minimal upkeep requirements and durability make it particularly suited to our variable climate.

Weed Resistance Benefits

Resin-bound gravel delivers outstanding weed resistance compared to its resin-bonded counterpart.

When stone and clear resin mix, they create a solid barrier that stops weeds from growing up through the surface. Think of it as laying a protective blanket over your garden path or driveway.

The surface lets rainwater drain through whilst preventing weeds from getting the moisture they need to thrive. This means less time spent pulling up unwanted plants and more time enjoying your outdoor space.

Resin-bonded gravel, however, tends to collect seeds in its gaps, making it more prone to weed growth.

For a smart, practical solution that keeps weeds at bay, resin-bound gravel is the clear winner.

Permeability and Drainage

Resin-bound surfaces excel at water drainage, with rainwater easily passing through to the ground below.

This porous system ticks all the boxes for sustainable urban drainage (SuDS) and helps prevent flooding by reducing surface water build-up – think of it like a giant sponge for your driveway.

Resin-bonded surfaces, however, are solid and waterproof, meaning you'll need extra drainage channels or gullies to handle rainfall properly.

Water Drainage Efficiency

Water drainage differs markedly between resin-bound and resin-bonded gravel surfaces, affecting their practical use across various settings.

| Feature | Resin-Bound Gravel | Resin-Bonded Gravel |

|---|---|---|

| Permeability | High (self-draining) | Low (non-permeable) |

| Water Management | Reduces puddling, flooding | Requires engineered drainage |

| Maintenance | Lower due to natural drainage | Higher due to water accumulation |

Think of resin-bound gravel as a sponge – water seeps through small gaps, making it brilliant for British weather. Resin-bonded gravel, however, acts more like a sealed surface, meaning you'll need proper drainage systems to prevent water pooling.

For a typical UK driveway, resin-bound surfaces handle heavy rainfall naturally, whilst resin-bonded requires additional drainage channels or gullies. This difference directly impacts both maintenance costs and how well the surface copes during wet weather.

SUDS Compliance Benefits

SUDS Compliance Benefits

The key distinction between resin-bound and resin-bonded gravel surfaces lies in their water drainage properties. Resin-bound surfaces are fully permeable, much like a natural lawn, making them SUDS compliant.

This brings practical benefits for UK property owners:

- Self-draining: No need for extra drainage channels or soakaways

- Cost-effective: Saves money by avoiding additional drainage installations

- Planning permission: Most UK councils don't require approval for resin-bound surfaces

- Eco-friendly: Naturally filters rainwater and reduces local flood risks

Think of resin-bound surfaces as a sponge that lets water pass through naturally, unlike traditional paving that creates puddles and runoff.

This makes them ideal for British weather conditions whilst meeting legal requirements for sustainable drainage.

Flood Risk Reduction

Resin-bound surfaces offer excellent flood protection in both homes and public spaces across the UK. These surfaces work by letting rainwater drain naturally through tiny gaps between stone and resin, much like a giant sponge.

Unlike traditional paving, which often leads to puddles and water build-up during heavy rainfall, resin-bound surfaces help prevent localised flooding. Think of it as nature's drainage system – when rain falls, instead of rushing down streets and overwhelming drains, the water steadily filters through the surface into the ground below.

This makes them particularly useful in areas prone to flooding or where council drainage systems struggle during storms. The surfaces also trap dirt and pollutants as water passes through, helping keep our groundwater cleaner.

They're tough enough for car parks and driveways, need little upkeep, and work well in both residential gardens and commercial spaces. For British weather conditions, they're a practical solution that helps manage our increasing flood risks.

Cost Considerations

Cost Considerations

The price of resin bonded gravel depends on several key factors that affect your overall budget. Understanding these costs upfront helps prevent unexpected expenses:

- Material Costs: £3.50 to £5.25 per square metre

- Labour Costs: Installation typically ranges from £650 to £1,000, varying by region and job complexity

- Project Size: Larger areas often work out cheaper per square metre

- Extra Costs: Factor in planning permission fees, delivery and site clearance

A standard driveway project (50 square metres) might cost between £2,500 and £3,500 total, including materials and labour.

Consider getting quotes from multiple contractors to ensure competitive pricing.

Careful budget planning across all these elements ensures your project stays on track financially.

Aesthetic and Customization

Resin bound gravel creates a smooth, modern finish, whilst resin bonded offers a more traditional, textured appearance.

Resin bound systems let you mix and match colours – perfect for matching your home's exterior or garden design.

Think of resin bound as having the smoothness of polished stone, whilst resin bonded gives you that classic gravelled driveway look.

Both options bring their own character to your outdoor space, whether you're after contemporary or traditional styling.

Visual Appeal Comparison

Visual Appeal: Resin-Bound vs Resin-Bonded Gravel

The choice between resin-bound and resin-bonded gravel makes a marked difference to your property's kerb appeal.

Resin-bound creates a smooth, contemporary finish – think of a pristine hotel driveway.

Resin-bonded delivers a more traditional, gravelly look, similar to country estate entrances.

Both systems offer varied colours, but resin-bound proves more versatile for designs. You can create everything from simple borders to complex patterns, much like indoor tiling.

Worth noting: Resin-bound keeps its smart appearance longer, whilst resin-bonded might develop patchy areas where stones come loose, particularly noticeable on driveways.

Customization Options Available

Resin-bound gravel offers plenty of ways to customise your outdoor space.

Create eye-catching patterns, from simple geometric shapes to natural designs, or add your company logo for a professional finish.

The colour options are extensive – choose warm, natural browns and greys, bold statement colours, or blend different stones to create your own unique mix.

Whether you fancy a smooth, modern look or a more textured finish, you can adapt the surface to match your taste and complement your property's style.

All these choices mean you can design an outdoor space that's distinctly yours, practical and visually striking.

Surface Texture Differences

Surface Texture Differences

Resin-bound and resin-bonded gravel systems offer distinct textures that affect their practical use. Consider these key differences:

- Resin Bound: Creates a smooth, level finish – ideal for patios and driveways where a polished look matters.

- Resin Bonded: Gives a coarser texture, much like a gravelled path, offering better grip in wet conditions.

- Design Options: Resin bound allows mixing of different-sized stones, perfect for creating bespoke patterns.

- Overall Look: Resin bound provides a neat, contemporary finish, whilst resin bonded looks more like traditional gravel.

The texture you choose will impact both the look and practicality of your space.

Consider foot traffic and intended use when deciding.

Suitable Applications

Suitable applications for resin-bound and resin-bonded gravel vary based on their unique properties.

Resin-bound works brilliantly for home driveways, garden paths and pool surrounds, creating a smooth, long-lasting surface that needs minimal upkeep. Its water-permeable nature makes it particularly useful for British weather conditions.

Resin-bonded gravel proves ideal for sloped driveways and areas needing extra grip, especially during wet weather.

In commercial settings, resin-bound surfaces are common in car parks and shopping centres, whilst resin-bonded gravel adds character to public spaces and parks.

Both options deliver durability and easy maintenance, serving as practical choices for a range of UK settings.

Key Components Comparison

The Essential Differences: Resin-Bound vs Resin-Bonded Gravel

Two distinct methods separate these popular driveway surfaces.

Resin-bound combines stones thoroughly mixed with resin, creating a smooth, water-permeable finish – much like a sponge letting rainwater through.

Resin-bonded, however, simply scatters stones onto resin, similar to spreading seeds on glue, forming a non-permeable layer.

Key distinctions:

- Resin-bound surfaces last longer and need minimal upkeep

- Resin-bonded costs less but tends to loosen over time

- Resin-bound stones are fully wrapped in resin, like chocolate-covered nuts

- Resin-bonded stones sit partially exposed, like pebbles stuck in cement

These fundamental differences matter when choosing your driveway surface, particularly given the UK's wet climate.

Finish Type Differences

Surface Finish Types

Resin-bound and resin-bonded gravel offer distinctly different finishes.

Resin-bound creates a smooth, even surface – imagine a perfectly levelled pavement – as the resin thoroughly coats each stone before laying. The result is a smart, modern finish that's particularly popular for driveways and patios across the UK.

Resin-bonded, meanwhile, delivers a more traditional gravelled look whilst keeping stones firmly in place.

Think of your local park's gravel paths, but with added stability. This rougher texture provides better grip in wet weather, making it ideal for public spaces and steep driveways.

Choose resin-bound for a contemporary, seamless finish, or opt for resin-bonded when you want the classic appearance of loose gravel with added practicality.

Environmental Impact

Environmental Impact

Resin-bound and resin-bonded gravel systems offer different environmental benefits, with resin-bound emerging as the more sustainable choice.

Resin-bound surfaces excel in sustainability through their permeable nature, which prevents flooding and naturally filters water back into the ground.

Key environmental advantages:

- Natural Drainage: Functions like natural ground, reducing water pollution and puddles

- Resource Efficiency: Uses natural aggregates and recycled materials, minimising waste

- Low Maintenance: Needs minimal cleaning and rarely requires chemical treatments

- SUDS Compliance: Meets UK sustainable drainage regulations, making it ideal for planning requirements

Resin-bonded gravel, being non-porous, offers fewer environmental benefits and typically requires more complex drainage solutions.

Long-Term Value Analysis

Long-Term Value Comparison

Resin-bound gravel offers better value over time compared to resin-bonded surfaces, despite higher upfront costs. The initial investment typically balances out through reduced maintenance and superior durability.

| Aspect | Resin-Bound Gravel | Resin-Bonded Gravel |

|---|---|---|

| Installation Cost | £40-£70 per m² | £26-£40 per m² |

| Lifespan | Up to 25 years | Shorter lifespan |

| Maintenance Frequency | Less frequent | More frequent repairs |

| Aesthetic Appeal | Highly customizable | Textured, rustic look |

| Compliance with SUDS | Yes | No |

The resin-bound option proves cost-effective for British homeowners, particularly in areas with heavy rainfall, as it meets Sustainable Urban Drainage System (SUDS) requirements. Think of it like choosing a quality winter coat – paying more initially for something that lasts longer and performs better often saves money in the long run.

Traffic Tolerance and Accessibility

Traffic Tolerance and Accessibility

When choosing materials for driveways and paths, you'll need to consider both durability and ease of access. Resin-bound gravel offers excellent performance in both areas.

For driveways, an 18mm depth provides proper vehicle support whilst maintaining structural integrity. The surface stays remarkably smooth – ideal for pushchairs, wheelchairs and those with limited mobility. Its anti-slip properties work brilliantly in typical British weather, and you won't spend endless weekends maintaining it.

Resin-bonded gravel, whilst slip-resistant, tends to be bumpier and less suitable for mobility aids. The bound version proves more hardwearing and lets you match the look to your property, making it the smarter choice for most UK homes.

Remember: choosing the right surface ensures both lasting durability and proper access for everyone who needs to use it.

Frequently Asked Questions

How Long Does the Installation Process Take for Each Type?

Installation times vary by project. A typical resin bound driveway (50m²) takes 1-2 days to complete, whilst resin bonded surfaces can often be finished in a single day. Larger areas or complex designs may require additional time. Weather conditions and proper surface preparation also impact completion times.

Can I Install Resin Gravel Myself, or Should I Hire a Professional?

DIY resin gravel installation is possible but risky without proper experience. Whilst you'll save money initially, mistakes can prove costly and require professional fixes later. A qualified contractor brings expertise, proper tools and quality materials, ensuring even coverage and lasting results. For driveways and high-traffic areas especially, professional installation is worth the investment.

What Weather Conditions Affect the Installation of Resin Gravel?

Installing resin gravel requires specific weather conditions for best results. The ideal temperature sits between 20°C and 25°C, with relative humidity ranging from 50-70%. Working outside these conditions risks poor adhesion – a particular concern during Britain's changeable weather. Best to check your local forecast and plan installation for a dry, mild day typical of late spring or early autumn.

Is Resin Gravel Safe for Pets and Children?

Resin gravel is safe for pets and children when properly installed, thanks to its smooth, bound surface that reduces tripping risks. Much like a tarmac playground, the sealed finish stops loose stones from being kicked up or swallowed. Just ensure the resin has fully set before allowing access – typically 24-48 hours after installation – and maintain regular supervision of young children and pets whilst they play.

How Do I Choose the Right Color for My Resin Gravel?

Choose resin gravel colours that match your property's style and surroundings. Light colours like cream or beige work brilliantly with modern homes, whilst darker greys and browns suit traditional British properties. Consider your existing garden features – if you've got red brick walls, warm-toned gravels will create a cohesive look. For coastal homes, sandy or pale blue tints echo the seaside setting. Remember that lighter shades show dirt more easily but make spaces appear larger, whilst darker colours add drama but can look gloomy in shaded areas.

Conclusion

When choosing between resin-bound and resin-bonded gravel for your driveway or garden path, it's important to understand their key differences. Resin-bound combines small stones with resin throughout the mixture, creating a smooth, puddle-resistant surface – think of a well-mixed bowl of porridge. Resin-bonded, however, involves scattering gravel onto a resin-coated surface, rather like applying grit to ice, resulting in a more textured finish.

Both systems have their merits. Resin-bound tends to be more expensive but offers better drainage and durability, whilst resin-bonded provides a traditional gravel look at a lower cost. Your choice might depend on practical needs – resin-bound works brilliantly for frequently used areas like driveways, while resin-bonded suits lighter-traffic paths and decorative areas.