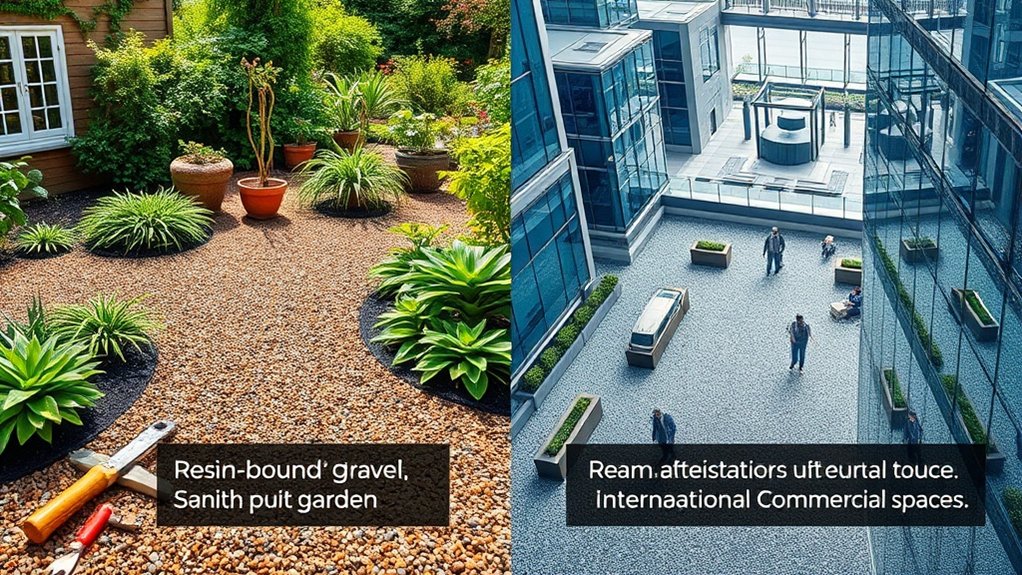

When comparing UK and international suppliers for resin-bound gravel, consider key factors such as cost, quality, and regulatory compliance. UK suppliers typically provide faster delivery, transparent pricing, and local support, which can be invaluable. In contrast, international suppliers may offer innovative materials that could enhance your project.

Pay attention to the choice of aggregates, as this affects both durability and appearance. Additionally, factor in ongoing maintenance costs, which can vary significantly. By understanding these aspects, you can make a more informed decision. For instance, if you prioritise quick installation and local support, a UK supplier might be the best choice. Explore further to maximise your investment.

Key Takeaways

- Domestic suppliers provide quicker delivery and support, which helps ensure your project finishes on time and reduces the risk of material damage.

- While international suppliers might offer a broader range of options, they often encounter shipping delays and extra costs.

- In the UK, prices for resin-bound gravel from domestic suppliers typically range from £50 to £120 per square metre, whereas international prices are between £50 and £76 per square metre.

- Choosing local aggregates from domestic suppliers promotes environmental sustainability by cutting down transport distances and lowering emissions.

- You’ll generally find quality assurance and technical support more readily available with domestic suppliers, which can enhance your installation and aftercare experience.

Understanding Local Regulations and Compliance

When planning a resin-bound gravel installation, it’s crucial to be aware of local regulations and compliance standards. This isn’t just about following rules; it can significantly influence the success of your project.

In the UK, for instance, you’ll need to adhere to REACH regulations, which mandate specific diisocyanate training for safe handling. Furthermore, compliance with SUDS (Sustainable Drainage Systems) regulations is essential to ensure your design allows for permeability, helping to prevent surface water flooding. Additionally, maintaining BBA approval ensures that your materials meet rigorous quality standards, further enhancing project reliability. Understanding the implications of planning permission is also critical, as obtaining it in conservation areas can be a complex process.

If your installation exceeds 5m², especially in conservation areas, you may also need to secure planning permission. Ignoring these regulations can result in rejected applications or expensive corrections.

Therefore, staying informed and ensuring your project meets local authority standards is vital.

Evaluating Product Quality and Performance

To ensure the success of your resin-bound gravel project, it’s crucial to evaluate product quality and performance. Important factors include material composition, installation depth, and performance benchmarks. International suppliers often excel in product innovations, particularly with advanced UV stability and chemical curing. While domestic products can also meet these standards, quality and price can vary. Additionally, resin bound paving is favored for its permeable qualities and durability, making it a popular choice among various applications. Choosing the right aggregate selection is essential for optimal durability and aesthetic appeal.

Here’s a brief comparison:

| Feature | Domestic Suppliers | International Suppliers |

|---|---|---|

| Resin Quality | Varies; premium options available | Advanced UV stability |

| Aggregate Specifications | Adheres to local guidelines | Meets universal standards |

| Load Resistance | Sufficient with proper installation | Up to 7.5 tonnes |

| Thickness Recommendations | Tailored to local climate | Universally adaptable |

Ultimately, achieving the right resin-aggregate ratios and following thickness guidelines will significantly enhance durability and performance.

Accessibility and Delivery Considerations

When choosing resin-bound gravel suppliers, local delivery is crucial for keeping your project on track and within budget. Domestic suppliers usually provide quicker delivery options, helping you avoid delays. In contrast, opting for international suppliers may lead to shipping issues that can complicate logistics and extend lead times. For instance, if you need materials quickly for a driveway renovation, sticking with a UK supplier can save you time and hassle. Additionally, many domestic suppliers offer permeable surfaces that enhance stormwater management, making them a more sustainable choice for your project. Local aggregates also contribute to environmental sustainability by reducing transport distances and emissions, further supporting green building practices.

Local Delivery Efficiency

Efficient local delivery is crucial when choosing resin-bound gravel suppliers, as it affects project timelines and costs directly. Domestic suppliers usually provide shorter lead times, often offering same-day or next-day service for local orders.

With a local inventory, they ensure popular aggregates and resin types are readily on hand, reducing waiting times. They can also accommodate custom mixes quickly, giving you more flexibility for your project.

Additionally, lower freight costs and the absence of import duties make budgeting easier. Shorter transport distances mean reduced risks of material damage, further streamlining the process.

Global Shipping Challenges

Global shipping opens up access to a wider variety of resin-bound gravel products, but it also brings significant challenges that can affect both accessibility and delivery times.

Delays are common due to long distances and complex logistics involving multiple carriers, which increases the risk of lost or damaged pallets. Ensuring high-quality packaging is crucial; if moisture protection is inadequate, it can compromise the product’s integrity, leading to rejections and higher costs.

Domestic suppliers often provide reliable stock availability, while international sources may experience stockouts or inconsistencies in product quality.

Additionally, customs clearance can unpredictably prolong delivery times, complicating the overall process.

Therefore, while international options may seem appealing, it’s important to weigh these challenges carefully to avoid costly delays in your resin-bound gravel projects.

Cost Analysis: Domestic vs. International Pricing

Understanding the cost dynamics of resin-bound gravel is crucial for your project budget, as domestic and international pricing differs significantly.

In the UK, domestic prices typically range from £50 to £120 per square metre. In contrast, international options, such as those from the US, are priced between £50 and £76 per square metre. This overlap is due to factors like resin quality and labour rates.

Domestic suppliers usually offer clearer pricing, helping you avoid hidden costs such as shipping and customs duties that come with international purchases.

While buying in bulk from abroad might seem cheaper, it often leads to higher overall expenses because of these additional fees.

Installation Support and Aftercare Services

When starting a resin-bound gravel installation, comprehensive support and aftercare services are crucial for a successful result.

UK suppliers excel in providing resources for installation, such as clear surface preparation advice suited to British weather conditions. They stress the importance of having a clean and level base and offer technical training through online courses to keep you informed about best practices.

Real-time technical support hotlines are available for on-site troubleshooting, helping you tackle issues like adverse weather.

Additionally, many suppliers offer quality assurance and certification programmes, ensuring that only qualified professionals install their systems, which can significantly improve the durability and performance of your installation.

Long-term Value and Maintenance Factors

When considering the long-term value of resin-bound gravel surfaces, it’s important to understand how maintenance affects their durability and appearance. Keeping them well-maintained ensures they last longer and remain attractive.

For example, regularly inspecting and sweeping the surface helps prevent drainage issues and weed growth, while cleaning up spills promptly maintains the integrity of the surface. Cautious power washing can effectively remove dirt without causing damage.

Seasonal tasks, like clearing autumn leaves and managing moisture, are vital to avoid slipping hazards. These simple maintenance steps can lead to lower ongoing costs compared to other paving options, making resin-bound gravel a smart long-term investment for both practicality and aesthetics.

Frequently Asked Questions

What Are the Environmental Impacts of Resin-Bound Gravel?

Resin-bound gravel provides several environmental benefits. Its permeable surface allows rainwater to drain away effectively, reducing flooding risks and promoting groundwater recharge. Additionally, many materials used can be recycled, which helps minimise waste. The durability of resin-bound gravel means it lasts longer, further decreasing the need for replacements. Lastly, following environmental regulations ensures that its installation and use have minimal impact on local ecosystems, especially in urban areas.

How Do I Choose the Right Color and Texture for My Project?

To select the right colour and texture for your project, start by assessing your design objectives. Think about how colours can create harmony or contrast. For example, pairing a soft blue with a warm yellow can bring a room to life. When it comes to texture, consider options that offer slip resistance, such as textured tiles for a bathroom, while also enhancing the overall look. Aim for a cohesive appearance that ties everything together seamlessly.

Are There Specific Warranties Offered by Suppliers?

When selecting suppliers, consider warranties as essential safety nets. Comparing warranties can show differences in coverage lengths and exclusions, which are crucial for gauging supplier reliability. Domestic suppliers typically offer warranties of 5 to 15 years, while international ones may extend beyond 20 years, providing greater peace of mind.

What Are Common Issues With Resin-Bound Gravel Surfaces?

Common issues with resin-bound gravel surfaces include installation difficulties, such as inadequate base preparation, and maintenance problems like surface cracking, discolouration, and loose aggregates. These issues can result in both aesthetic and structural deterioration over time. For instance, if the base isn’t properly compacted, it can lead to uneven surfaces, while discolouration might occur due to UV exposure or staining from spills. Regular maintenance is essential to keep the surface looking its best and ensure its longevity.

How Can I Ensure Proper Drainage With Resin-Bound Gravel?

To ensure proper drainage with resin-bound gravel, it’s essential to get it right from the start. Prioritise effective drainage solutions by using a porous base to allow water to flow through. Additionally, maintain a gradient of 1-2% to direct water away effectively. For instance, if you’re installing a driveway, ensure it slopes slightly towards the edges or a drainage channel. This approach will help prevent water pooling and keep your surface functional and safe.

Conclusion

When navigating the resin-bound gravel market, you’re essentially balancing quality, cost, and support. Choosing between domestic and international suppliers can feel like finding your way through a thick forest; each option presents its own challenges and benefits. By carefully examining regulations, product performance, and long-term value, you can ensure your investment lasts. Ultimately, the right choice will not only improve your space but also provide peace of mind for years ahead.