Calculate your resin-bound driveway costs by first measuring the total area in square metres (length x width). Select premium materials, including UV-stable resin and properly graded aggregates – vital for our British weather. Check your site’s drainage and ground stability, particularly important in areas prone to flooding or with clay soil. Labour costs typically range from £40-£75 per square metre in most UK regions, varying by postcode and project complexity. Remember to account for council permits and building regulations where applicable. A typical UK double driveway (roughly 50 square metres) might cost between £3,500-£5,000 for materials and labour combined.

Key Takeaways

Measuring Up Your Resin Driveway

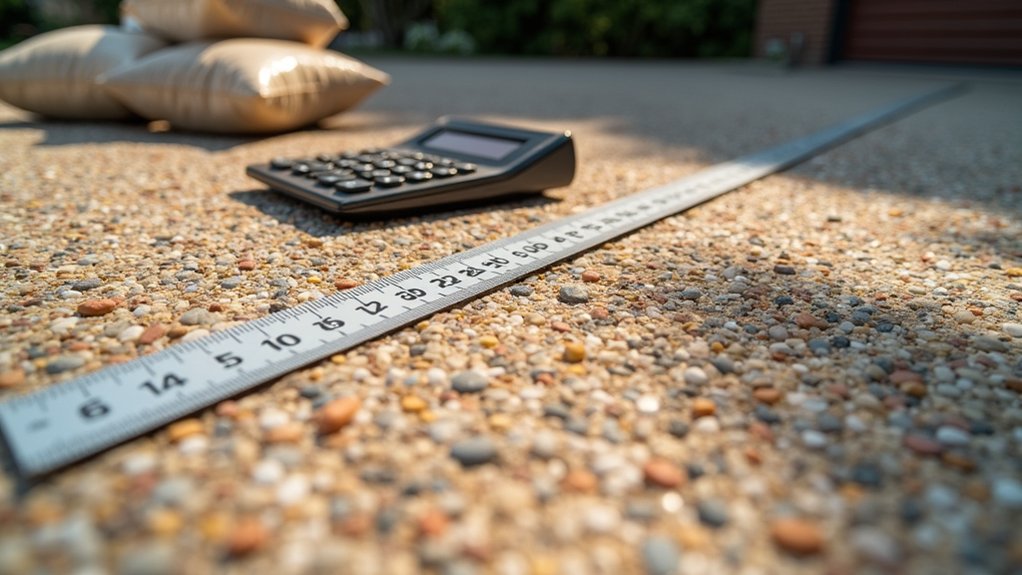

Get the basics right by measuring length times width in square metres – this is crucial for accurate quotes.

Quality matters – opt for UV-resistant resin and local stone aggregates to prevent yellowing and ensure your driveway lasts.

Labour costs vary across the UK, typically £9-£14 per square metre. Steep or difficult access might push this higher.

Don’t forget planning permission – costs between £50-£200 in most councils. Best to sort this early as it takes 2-4 weeks.

Extra costs to consider:

- Ground preparation (especially for uneven surfaces)

- Custom colours (popular for matching property aesthetics)

- Decorative edges or borders

- Drainage solutions if needed

These extras can add 20-30% to your base cost, but they’re worth considering for a proper job.

Understanding Driveway Size and Shape

Planning your resin-bound driveway starts with proper measurements to nail down costs. Grab your tape measure and record the length and width, then multiply these to find your total area in square metres.

Got curves or odd angles? Use a flexible tape measure to get spot-on measurements. It’s worth sketching your driveway on paper – nothing fancy, just a rough drawing to help you visualise the finished project and spot any tricky areas. The choice of aggregate options can also impact the overall appearance and functionality of your driveway.

Think about typical UK driveways: a straight run from pavement to garage might be straightforward to measure, whilst a curved entrance with a turning circle needs more careful attention.

Getting precise measurements means you’ll avoid ordering too much or too little material, saving you money in the long run. Remember, proper thickness is crucial to ensure stability and longevity of your driveway.

Choosing the Right Materials and Aggregates

Selecting Materials and Aggregates

The success of your resin-bound driveway hinges on proper material choice. UV-stable resins are essential for British weather, preventing yellowing and degradation from sunlight. Additionally, opting for UV stability in your resin will greatly enhance the longevity of your driveway.

For aggregates, opt for angular stones rather than rounded ones – they lock together better, much like a jigsaw puzzle. Most UK installations work best with 2-5mm stones, though larger 6-10mm ones suit rustic properties. The minimum depth for resin driveways of 18mm is crucial for ensuring longevity.

Quality matters – avoid cheap imported aggregates that might break down. Local quarry-sourced stones, like Cotswold or Scottish granite, not only last longer but complement British architecture.

A non-slip surface treatment is worth considering, particularly for our wet climate.

Think of your driveway as a long-term investment – choosing premium materials now saves money on repairs later.

Aggregate Material Options

Selecting the right aggregates for your resin driveway makes all the difference to its durability and looks. Consider these key points:

- Source aggregates from trusted UK suppliers – think Travis Perkins or Jewson – to ensure quality.

- Your stones must be clean and thoroughly dry, much like preparing a surface for painting.

- Mix 1-3 mm and 2-5 mm stones (about the size of small pebbles) for the best grip and strength. Using UV-stable solutions can aid in preventing yellowing and sun damage over time.

- Check stones are properly graded – you wouldn’t want patches looking different from one another.

- Add C52 sand to achieve a smoother finish, similar to grouting between tiles. Additionally, using high-quality resin will enhance the overall performance and longevity of your driveway.

These choices will give you a robust, attractive driveway that stands up to British weather whilst looking smart for years to come.

Resin Type Selection

Choosing the right resin for your driveway is crucial for its durability and performance. Polyurethane resin stands out as the top choice in the UK, offering excellent strength and flexibility. It handles our varied British weather brilliantly, moving with the ground to prevent cracks, and typically lasts 15-25 years.

Whilst epoxy resin costs less upfront, it tends to yellow in sunlight and only lasts 5-15 years, making it poorly suited to outdoor use.

For areas with heavy rainfall – common across Britain – SUDS-compliant resins help manage water effectively and reduce flood risks. UV-stable resins are essential for British driveways to combat sun damage and maintain their appearance.

The smart choice of resin means the difference between a driveway that stays looking fresh for decades and one that needs replacing after a few years.

Surface Treatment Choices

Surface Treatment Choices

Once you’ve chosen your resin, you’ll need to decide on surface treatments and aggregates for your driveway. These choices impact both looks and functionality:

- Aggregate Size: Standard UK grades of 1-3mm or 2-5mm work best for proper drainage.

- Colour Blends: Natural stone like Cotswold or slate, or recycled glass for a modern look.

- Design Features: Add postcode numbers or simple borders to personalise.

- Surface Finish: Anti-slip treatment is essential for wet British weather.

- Upkeep: Low-maintenance options save time and money in the long run.

Smart choices in these areas ensure your resin driveway looks great and performs well year-round.

Assessing Site Conditions

Checking Your Site Before Installation

Give your ground a thorough check to ensure it’s stable enough for a resin driveway – soft or shifting soil simply won’t do.

The site needs proper slopes and drainage to stop rainwater collecting in puddles, which is particularly important given our British weather.

Make sure there’s enough space for delivery lorries to access the site with materials and equipment – a narrow side passage or tight garden gate could cause problems.

A quick walk-round of your property should spot any potential snags before work begins.

Evaluate Ground Stability

Ground stability checks are vital before installing a resin-bound driveway across your property. Key assessment methods include:

- Soil testing: Basic soil strength tests reveal how well your ground will support the new surface.

- Sample drilling: Taking core samples at different depths shows what’s really under your feet.

- Checking water levels: Poor drainage often means unstable ground – look for puddles or waterlogged areas.

- Tree and plant impact: While some root systems help hold soil together, large trees near your driveway might cause problems.

- Past ground works: Any old building work or utility trenches could create weak spots that need attention.

A proper stability check helps avoid costly repairs down the line.

Most UK contractors can arrange these tests as part of their initial survey.

Analyze Slope and Drainage

Analysing slope and drainage is vital for a proper resin-bound driveway installation.

Check your site’s slope first – a gentle gradient ensures stability during the laying process. Good drainage is crucial; without it, you’ll face puddles and water damage.

Add drainage channels where needed, though resin-bound surfaces are naturally permeable, helping prevent floods. For steeper sections, consider anti-slip additives – particularly useful during wet British weather.

Sound ground preparation and a stable base are essential. Think of it like building a house – the foundations matter most.

These steps aren’t just box-ticking exercises; they’re the difference between a driveway that lasts 15 years and one that fails after the first winter.

Focus on these basics, and you’ll have a driveway that handles everything from summer downpours to winter frost without issue.

Check Accessibility Factors

Key accessibility checks for your resin-bound driveway installation:

- Examine your current surface – whether it’s concrete, tarmac or block paving – to ensure it’s sound and stable.

- Look for any physical barriers like garden gates, hedges or walls that might limit machinery access.

- Check your existing drainage works properly, as poor drainage can damage your new surface.

- Make sure the ground can handle heavy vehicles and equipment (particularly important for older properties).

- Allow enough working space around the area, typically 2-3 metres, for installers to move freely with tools.

Most UK driveways need between 1-3 days for installation, depending on size and accessibility.

Tight spaces or tricky access points might require specialist equipment or extra time, affecting your overall costs.

Remember: A thorough check now prevents delays and extra expense later.

If you’re unsure about any aspects, ask your installer to assess the site before work begins.

Evaluating Labor Costs

Labour costs form a crucial part of any resin-bound driveway project and often make up a significant portion of your budget. Skilled installers with proper training are essential, as their expertise directly affects the final result.

In the UK, labour typically costs between £9 to £14 per square metre, though prices vary by region.

Your costs will increase if the project involves:

- Complex groundwork

- Irregular shapes

- Custom patterns

- Steep gradients

- Hard-to-access areas

Check local rates and get multiple quotes from qualified contractors, as prices differ considerably between London and other regions. Northern areas generally charge less than southern counties, while major cities tend to command premium rates.

Understanding these factors helps you plan your budget more effectively and avoid unexpected costs during your driveway installation.

Factoring in Permits and Inspections

Planning Your Resin Driveway: Permits and Inspections

Getting the right paperwork sorted for your resin driveway is crucial in the UK. Most councils require proper permissions, especially if you’re changing from a garden to a driveway or altering drainage.

Essential steps:

- Ring your local council’s planning department to check specific requirements

- Budget for permit costs (typically £50-200, varying by region)

- Schedule building control inspections where needed

- Keep all paperwork in a safe place

- Add 2-4 weeks to your timeline for permit processing

Many UK homeowners skip this step and face fines later – particularly if the driveway doesn’t meet SUDS (Sustainable Urban Drainage Systems) requirements.

Planning permission is especially important if you live in a conservation area or listed building.

Analyzing Material Costs

Material costs for resin-bound driveways need careful planning to avoid budget overruns. The main components – resin and aggregate – cost between £40-£70 per square metre. Premium aggregates or bespoke colours will push prices higher, whilst UV-stable resin costs more but offers better durability.

To work out your costs:

- Measure your driveway area in square metres

- Factor in aggregate depth requirements

- Add costs for extras like edging stones and drainage

For example, a typical 50m² driveway might need:

- Basic resin and aggregate: £2,000-£3,500

- Edging stones: £200-£400

- Drainage materials: £150-£300

Choose materials based on both budget and long-term durability needs. Quality materials might cost more initially but often prove more cost-effective over time.

Estimating Labor and Installation Costs

Labour and Installation Costs: A Guide

Getting accurate labour costs is vital when planning your resin-bound driveway. Most UK contractors charge between £40 and £120 per hour, though rates vary by region. Your total cost will depend on several key factors:

- Project scope: A standard 50m² driveway typically takes 1-2 days

- Installer expertise: Qualified contractors command higher rates but often deliver better results

- Ground preparation: Fixing damaged surfaces or poor drainage adds extra costs

- Technical requirements: Proper resin mixing and application need specialist skills

- Local planning permission: Check with your council for any required permits

Remember: The cheapest quote isn’t always the best value. Local contractors with proven experience often provide more reliable, long-lasting results.

*Tip: Get at least three detailed quotes to compare prices and services offered.*

Considering Site-Specific Factors

Site-Specific Factors to Consider

When planning a resin-bound driveway, several key site factors affect both installation and costs.

| Factor | Considerations |

|---|---|

| Drainage Solutions | Ensure proper soakaway or permeable base for rainfall management |

| Base Material | Use stable materials like permeable no-fines concrete |

| Site Topography | Check slopes and access for installation requirements |

Good drainage is crucial – it’s not just about meeting UK regulations but protecting your investment long-term. Think about your garden’s slope and any existing drainage issues. For example, if your property sits at the bottom of a hill, you’ll need more robust drainage solutions.

The site’s layout directly influences your material choices and installation methods. A properly prepared base (much like building a house’s foundations) prevents common problems such as cracking and ensures your driveway stays solid for years to come.

Identifying Additional Costs and Considerations

Additional Costs to Consider for Your Resin Driveway

The base price is only the starting point when planning a resin-bound driveway. Factor in these extra costs for a realistic budget:

- Premium aggregates or eco-friendly materials typically raise the price by £5-£15 per m²

- Bespoke colours and patterns add £2-£5 per m²

- Decorative edging or contrasting borders increase labour costs by 10-15%

- Underfloor heating systems cost between £2,500-£7,000

- Ground preparation and excavation work ranges from £800-£2,000

These figures vary by region, with London and the South East generally commanding higher prices.

It’s worth getting multiple quotes from local installers, as prices can differ significantly between contractors.

[Note: all prices are approximate and may vary based on location and market conditions]

Frequently Asked Questions

How Long Does a Resin-Bound Driveway Typically Last?

A well-installed resin-bound driveway lasts between 15 and 25 years in the British climate. The lifespan depends heavily on the quality of materials used and proper installation by qualified professionals. Much like traditional block paving, regular maintenance and prompt repairs of any damage will help maximise its durability. When considering replacement, factor in your property’s needs and local weather conditions to ensure you get the best value for money.

Can I Install a Resin Driveway Myself?

You can install a resin driveway yourself, though it’s a complex job requiring careful planning. Whilst saving on labour costs, you’ll need to budget for proper materials, specialist tools and safety gear. The key to success lies in thorough base preparation and precise resin mixing – get these wrong, and your driveway won’t last. Like laying a quality patio, attention to detail makes the difference between a professional finish and a costly do-over.

What Maintenance Is Required for a Resin Driveway?

Regular sweeping and hosing down keeps your resin driveway in top condition. Tackle any spills or stains straight away – particularly oil and petrol – and stick to mild cleaning solutions to protect the surface. Like any garden path, a quick sweep after autumn leaf fall or muddy weather helps maintain its smart appearance.

Are There Eco-Friendly Resin Options Available?

Several eco-friendly resin options exist in the UK market. These use sustainable materials, including recycled glass and natural aggregates, which help reduce landfill waste whilst maintaining the quality of traditional resin surfaces. The green alternatives offer proper drainage capabilities and a durable finish, making them suitable for both driveways and garden paths. Common examples include bio-based resins and those made with recycled plastic content – both offering the same attractive finish as standard options but with a lower environmental impact.

How Do Weather Conditions Affect Installation Timing?

Weather plays a crucial role in installation timing. The ideal temperature sits between 5°C and 25°C – think typical British spring or autumn days. Avoid laying during rain or when it’s too humid, as moisture interferes with the resin’s ability to set properly. For best results, check the weather forecast and plan your installation for a dry spell with moderate temperatures.

Conclusion

Taking time to cost out your resin-bound driveway is a practical first step that’ll save you money and hassle down the line. Think of it like planning your weekly shop – you’ll want to know exactly what you’re spending before you commit. A well-researched estimate helps you budget properly and avoid any nasty surprises. Get your measurements right, factor in materials and labour, and you’ll be set for a driveway that adds real value to your home whilst looking brilliant.