Choosing the right resin-bound gravel needn't be complicated. Start with UV-stable resins that won't yellow under British weather – particularly important for driveways and garden paths exposed to our variable climate. Look for durable options that can handle daily foot traffic and occasional vehicle use, much like traditional gravel but without the scatter. Good drainage is crucial for our rainy weather, so ensure your chosen mix allows proper water flow. When it comes to installation, a solid sub-base is as important as the resin itself – think of it like foundations for a house. Pick a contractor who's done similar work locally and can show you examples of projects from at least two years ago. A proper warranty should cover both materials and workmanship for peace of mind.

Key Takeaways

Essential Tips for Resin-Bound Gravel Selection

UV-stable resin is crucial for outdoor spaces – it won't yellow or degrade under British sun and rain, making it ideal for driveways and garden paths.

A solid foundation matters enormously. Tarmac or concrete bases work best, much like building a house on firm ground rather than sand. Without proper foundations, you'll risk cracks and dips.

Sort your drainage from the start. British planning regulations require Sustainable Urban Drainage Systems (SUDS), plus good drainage prevents annoying puddles and potential frost damage in winter.

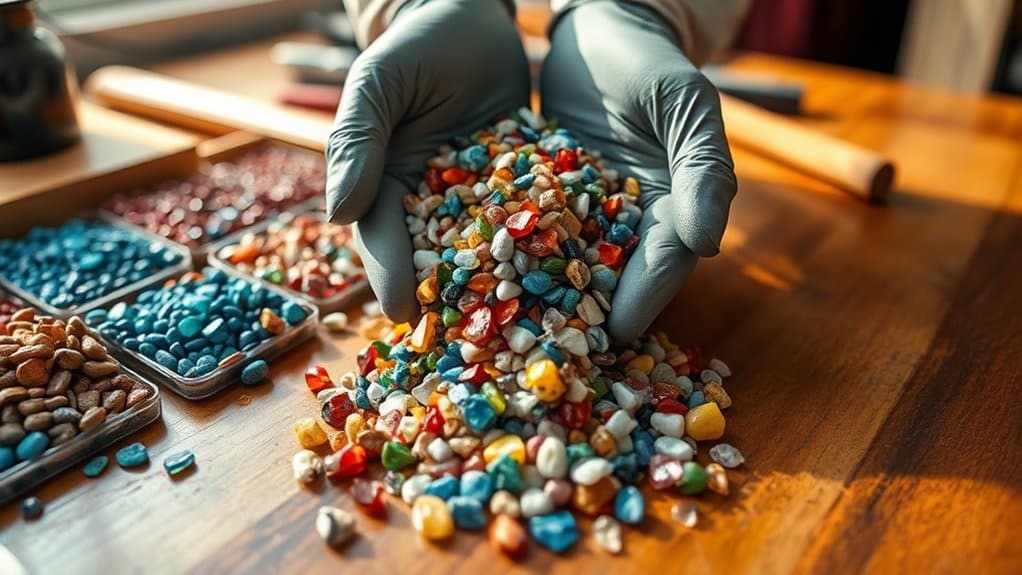

Pick top-quality stones that suit your needs. Smaller aggregates (2-5mm) work brilliantly for pathways, whilst larger ones (6-10mm) are spot-on for driveways.

Check your installer's credentials thoroughly. Look for FeRFA membership and solid warranties – cowboy builders are the last thing you want on a significant investment like this.

Understanding Resin-Bound Gravel Types

Different resin types offer unique benefits for your gravel project, and choosing the right one is crucial.

UVR resin won't fade in British sunlight, making it perfect for driveways and garden paths. Additionally, resin bound surfaces are highly resistant to cracking and UV degradation, ensuring longevity and durability for your outdoor spaces. The use of UV-resistant resin guarantees excellent colour stability under British weather conditions.

Polyurethane resin handles our varied weather brilliantly, offering both flexibility and UV protection – ideal for areas that experience frequent temperature changes.

Whilst epoxy resin provides strong bonding, it's rather rigid and best suited for stable surfaces.

Non-UV resin works well indoors but tends to darken when exposed to sunlight, so it's best kept for garages or covered spaces.

For the best finish, pair your chosen resin with suitable aggregates like stone or recycled glass. The right combination will ensure your surface looks great and performs properly for years to come.

Key Benefits of Using Resin-Bound Gravel

The right resin choice for your gravel project is crucial, but knowing the core benefits makes the decision straightforward.

| Benefit | Description |

|---|---|

| Durability | Stands up to British weather and daily vehicle use. |

| Design Flexibility | Mix and match colours and finishes to suit your property. |

| Environmental Sustainability | Water-permeable surface prevents pooling and meets SUDs requirements. |

| Low Maintenance | Minimal upkeep needed, stops weeds and stays intact. |

These benefits boost your property's kerb appeal whilst providing a practical, eco-friendly solution for driveways and paths. Resin-bound gravel delivers both visual appeal and environmental responsibility, making it a sound investment for UK homeowners. Additionally, the porous nature of resin-bound driveways enhances surface runoff absorption into the ground below, further contributing to environmental sustainability. Furthermore, this design not only improves effective water drainage by significantly reducing the risk of flooding but also enhances the overall durability and longevity of the driveway.

Selecting the Right Resin for Your Needs

Choosing the right resin for your gravel project makes all the difference in its durability and looks. UV stability is crucial – especially for British weather conditions. UV-stable resin (aliphatic) works best for driveways and garden paths, keeping its colour even in direct sunlight. Non-UV resin (aromatic) tends to yellow and darken, particularly noticeable in our varied climate. It's important to consider the base options you will use, as a suitable base will enhance the longevity and performance of the resin-bound surface.

Think about where you'll use it. A front drive needs different properties than a sheltered patio. Whilst non-UV resin costs less up front, it's often a false economy. UV-stable resin might cost more initially, but it cures quickly and typically comes with a 15-year guarantee – worth considering for our wet and changeable weather. The exceptional durability of resin surfaces makes them a fitting choice for areas with heavy vehicle traffic.

British-made UV-stable resins are tested for our climate and meet local building standards, making them a sensible choice for UK projects.

Important Installation Considerations

Essential Installation Tips for Resin-Bound Gravel

Proper installation of resin-bound gravel requires careful attention to several key factors. Start with your base – it must be solid, such as tarmac or concrete, and properly compacted to prevent future sinking.

Sort out drainage early on to meet SUDS requirements, which are mandatory for UK properties.

Choose a dry day with low humidity for installation, as moisture can affect curing. Pick quality aggregates in suitable sizes – think pea-sized for pathways, slightly larger for driveways.

Layer thickness matters: 15-18mm works well for paths and patios, whilst driveways need 18-20mm for vehicle weight.

Mix ratios are critical – follow manufacturer guidelines precisely. For the finished look, proper trowelling ensures an even surface and consistent colour throughout.

A skilled hand makes all the difference between a botched job and professional results.

Evaluating and Choosing the Right Contractor

Selecting Your Resin Driveway Contractor

Key qualifications to check:

- Membership with trusted UK bodies like the Federation of Master Builders

- British Standards compliance and ISO 9001 certification

- Strong local references and verifiable customer reviews

- Solid warranty terms, ideally 10+ years

- Specialist training in resin-bound surfacing

Contact at least three contractors and compare their quotes.

Ask to see completed projects, particularly ones from your local area that are several years old. A reliable contractor should promptly answer your questions and clearly explain their process.

Look for red flags like unusually low quotes or pressure to decide quickly.

Most reputable UK contractors will be happy to provide references from recent customers and evidence of their qualifications.

Remember: The cheapest quote isn't always the best value – focus on experience, proven quality and proper credentials.

Frequently Asked Questions

How Long Does Resin-Bound Gravel Last?

Resin-bound gravel surfaces last between 20 to 25 years with proper care, much like a well-built patio or driveway. The longevity depends heavily on the quality of both the subbase (think solid foundations) and the resin used. Simple maintenance, such as regular brushing and avoiding parking lorries or heavy machinery on it, keeps the surface in top condition. Think of it as you would a carpet – the better you look after it, the longer it serves you.

Can Resin-Bound Gravel Be Installed Over Existing Surfaces?

Resin-bound gravel works brilliantly over existing surfaces, much like laying a new carpet over solid floorboards. The key is proper prep work – your base surface must be stable, clean and crack-free. Think of it as painting a wall – you wouldn't start without sorting the surface first. Common surfaces like concrete and tarmac work particularly well, though they must be structurally sound. A properly prepared surface ensures your new resin-bound driveway or path will last for years to come.

Is Resin-Bound Gravel Suitable for Winter Conditions?

Resin-bound gravel holds up brilliantly in British winters, providing excellent grip even in icy conditions. The surface stays stable during our typical freeze-thaw weather, unlike traditional gravel that can scatter about. Think of it as having the look of loose gravel but without the faff of constant maintenance – particularly useful when you're dealing with winter's worst. The material won't crack or lift like tarmac often does, making it a proper year-round solution for driveways and paths.

What Colors and Textures Are Available for Resin-Bound Gravel?

Natural stone tones dominate the resin-bound gravel range, from warm beiges to rich greys and charcoals. Colour options include traditional limestone shades, golden-hued gravels and earthy browns. For texture, choose between smaller aggregates for a smoother finish or larger stones for more distinctive surface detail. The combinations available match practically any garden or driveway design scheme.

How Is Resin-Bound Gravel Repaired if Damaged?

Repairing resin-bound gravel requires a thorough clean of the damaged spot, followed by applying specialised patch repair resin with proper mixing ratios. The repair must cure fully – typically 24 hours in dry conditions. Regular maintenance involves a quick sweep and occasional wash with mild soap to keep the surface looking sharp. For best results, avoid harsh chemicals or pressure washers, as these can compromise the surface.

Conclusion

The right resin-bound gravel choice is crucial to your project's success. Thorough research into different aggregates and resin types will save you time and money in the long run. Consider factors like local weather conditions and expected foot traffic – what works brilliantly for a quiet garden path might not suit a busy driveway. When it comes to installation, choose experienced contractors with solid UK credentials and ask to see their previous work. Quality materials and proper installation will ensure your surface remains attractive and functional for years to come.