Resin-bonded driveways need significantly more maintenance than their resin-bound counterparts. You’ll need regular weekly sweeping and yearly cleaning to stop dirt collecting and prevent the surface from flaking. Resin-bound surfaces are much simpler to maintain – just give them an occasional blast with a pressure washer and check for weeds once a year. The lower maintenance requirements of resin-bound driveways make them more cost-effective in the long run, much like choosing a low-maintenance garden over a high-maintenance one.

Key Takeaways

Resin-bonded driveways are far more demanding on the maintenance front compared to their resin-bound counterparts.

With resin-bonded surfaces, you’ll need to sweep weekly to prevent dirt build-up, plus there’s the faff of annual deep cleaning. Keep an eye out for loose stones and flaking – these surfaces often need fixing every 5-10 years.

Resin-bound driveways are much more straightforward. A quick pressure wash now and then keeps them looking smart, and you won’t need to think about serious repairs for 20-30 years. Think of it like comparing a high-maintenance sports car to a reliable family motor.

The extra upkeep of resin-bonded drives means you’ll be spending more time and money in the long run. If you’re after a low-maintenance option, resin-bound is clearly the better choice.

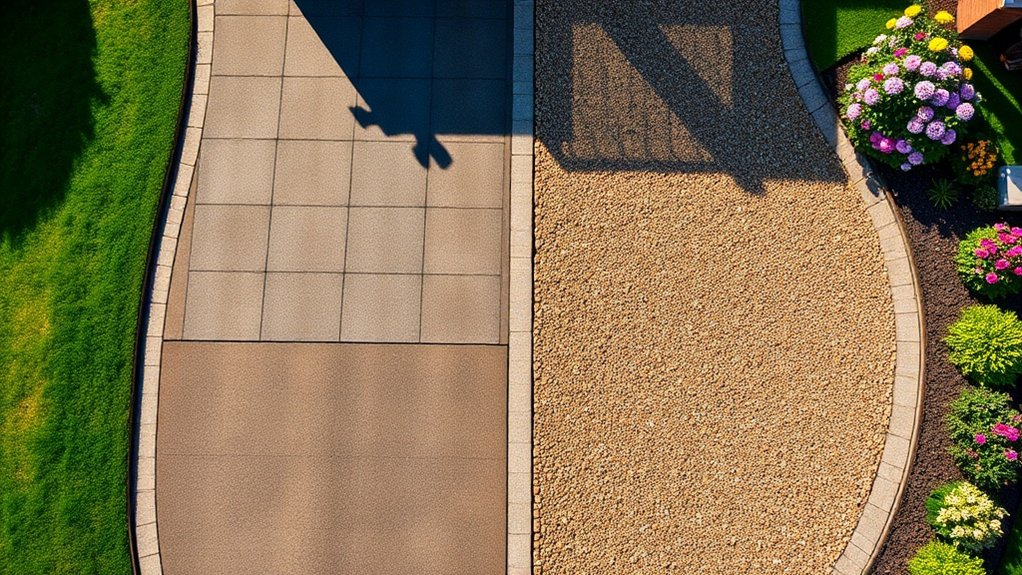

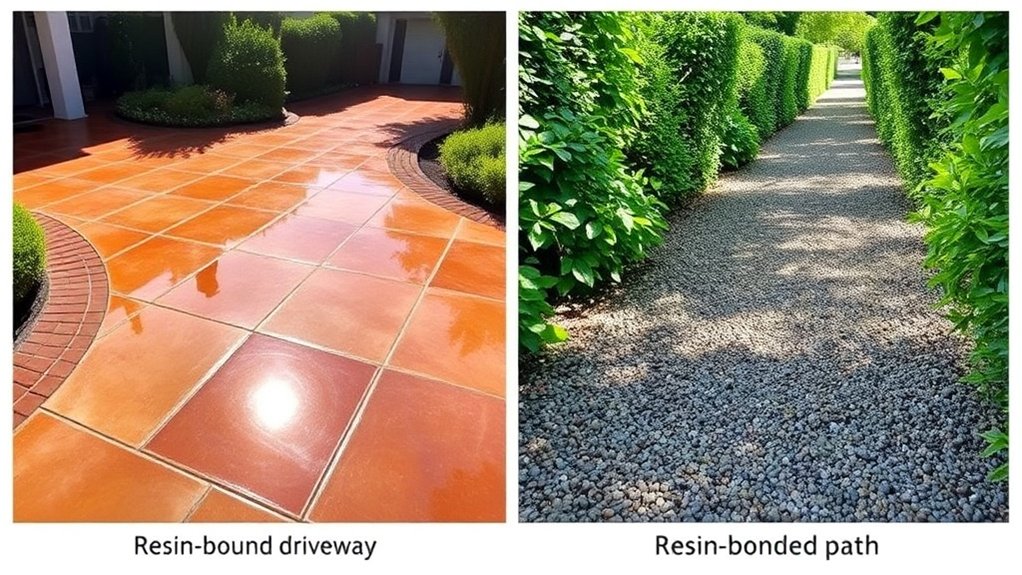

Understanding Resin-Bonded Driveways

Resin-bonded driveways provide a decorative finish using natural stone aggregate fixed to a surface with resin. The thin 3-6mm layer gives you an attractive, textured appearance, much like loose gravel but without the scatter.

Think of it as a coat of stone-flecked paint for your driveway.

Whilst offering some drainage, these driveways aren’t as water-permeable as their resin-bound cousins. Over time, you might notice loose stones breaking away – a common issue that requires attention. Regular maintenance is crucial: sweep weekly to prevent dirt build-up and give it a thorough clean yearly, just as you’d your patio. Proper maintenance is essential for ensuring that the driveway remains functional and appealing over time, particularly given the regular maintenance needed to address potential issues with loose stones.

If you’re looking to spruce up an existing concrete or tarmac driveway, resin-bonded surfacing offers a cost-effective facelift.

Mind you, it’s worth factoring in the ongoing upkeep to keep it looking smart.

Understanding Resin-Bound Driveways

Resin-bound driveways offer excellent drainage properties, making them ideal for the British climate. Water seeps straight through the surface rather than pooling, which helps prevent flooding during heavy rainfall. These driveways prove remarkably durable and require minimal upkeep – you won’t need to spend weekends pulling weeds, as they simply can’t take root. Additionally, they have a durability that lasts between 15 to 25 years with proper maintenance. This longevity is further supported by their UV-stable resin, which prevents fading and enhances long-term value. It’s no wonder they’ve become a favourite amongst UK homeowners looking for a practical, long-lasting driveway solution.

Permeability and Drainage Benefits

Resin-bound driveways offer excellent permeability and drainage, making them ideal for Britain’s rainy climate. The mixture of resin and fine stones creates a surface full of tiny spaces that let rainwater soak through—much like a sponge. This system cuts surface water runoff by more than half, helping prevent localised flooding that’s becoming more common in UK towns and cities. Unlike traditional resin-bonded surfaces, which often lead to puddles forming, resin-bound driveways work with nature’s water cycle. They’re fully compliant with Sustainable Urban Drainage Systems (SuDS), which is crucial for new builds and renovations across the UK.

In fact, permeability rates can reach up to 95%, enhancing the surface’s ability to manage heavy rainfall effectively. Think of it as giving rainwater a proper route back into the ground, rather than forcing it into already-strained drainage systems. The benefits are clear: less waterlogging, better support for nearby plants and gardens, and reduced pressure on local drainage networks. Additionally, permeable driveways help combat urban flooding by allowing water to drain into the soil and aquifers.

For British homeowners dealing with increasing rainfall, a resin-bound driveway offers a practical solution that’s both environmentally sound and low-maintenance.

Durability and Longevity Factors

Durability and Longevity Factors

A resin-bound driveway’s performance hinges on its durability and longevity. Much like a well-built house needs solid foundations, these driveways require proper planning and execution to stand the test of time.

| Factor | Importance |

|---|---|

| Quality of Materials | Prevents fading and wear |

| Installation Techniques | Guarantees even surface and strength |

| Sub-base Preparation | Supports load distribution |

| Weather Impact | Reduces cracking and degradation |

| Maintenance Requirements | Extends lifespan and preserves quality |

Top-quality materials and expert installation are non-negotiable for British weather conditions. A properly laid sub-base proves crucial, particularly for handling heavy vehicles and frequent use. Think of it as building a motorway – the groundwork matters as much as the surface.

Regular maintenance, whilst minimal, keeps the surface in top nick. A quick pressure wash twice yearly and occasional sweep typically suffice, making it a practical choice for UK homeowners.

Weed Resistance Advantages

Resin-bound driveways excel at keeping weeds at bay compared to other surfaces. The tight bond between resin and stones leaves minimal gaps where weeds typically take root. A pre-installation weed treatment provides added protection from the start.

Think of the surface like a smooth tabletop – seeds simply can’t get a proper foothold to grow.

Whilst the odd weed might pop up around the edges (much like they do between garden pavers), they’re easy to deal with. Simply pull them out by hand or treat with a standard garden weed killer.

To keep your driveway weed-free, give it a regular sweep and an annual power wash. This maintenance routine, much like hoovering your carpet, keeps the surface clean and prevents weeds from getting established.

Installation Costs: Resin-Bonded vs. Resin-Bound

Resin-bonded driveways cost £15-£30 per square metre, whilst resin-bound systems run £50-£100 per square metre.

The higher price of resin-bound surfaces reflects their more complex installation process and premium materials.

However, resin-bound surfaces often prove more cost-effective long-term, thanks to better durability and lower maintenance costs.

Initial Installation Expenses

Initial installation costs for resin driveways vary between the two main types. A straightforward comparison:

| Type | Average Cost per m² |

|---|---|

| Resin-Bound | £90 – £140 |

| Resin-Bonded | £55 – £70 |

A typical double driveway (roughly 40m²) costs between £3,600 and £5,600 for resin-bound, whilst resin-bonded starts from £2,200. Base preparation work adds £15-25 per m² to these figures.

Material quality and ground preparation significantly influence final costs. Higher-grade resins and proper substrate preparation, though costlier initially, often prove more economical long-term through reduced maintenance needs.

Long-Term Cost Implications

Long-Term Costs

A resin driveway’s true value lies in its ongoing costs, not just the initial outlay. Resin-bound surfaces prove their worth over time, typically lasting 20-30 years with minimal fuss. You’ll only need an occasional pressure wash to keep them looking fresh.

Resin-bonded surfaces, whilst cheaper to install, tend to be more troublesome. They often shed loose stones and flake after 10-15 years, meaning more frequent repairs and potential replacements. Think of it like choosing between a quality pair of boots that last years versus cheaper ones needing replacement every season.

The sealed nature of resin-bound driveways helps them withstand British weather better, cutting down on repair costs. Though pricier upfront, they’re usually the smarter financial choice in the long run – much like investing in proper home insulation.

For UK homeowners watching their pennies, the extra initial investment in resin-bound surfaces typically pays off through reduced maintenance costs and longer life expectancy.

Long-Term Maintenance Expenses

The cost differences between resin-bound and resin-bonded surfaces become quite stark over time.

Resin-bound surfaces, whilst pricier to install, prove their worth by lasting 25+ years with minimal fuss – just the odd sweep now and then, much like a regular patio.

Resin-bonded surfaces, however, can be a bit of a headache. Their thinner top layer means loose stones often need replacing, particularly on busy driveways or paths.

Think of it like maintaining a gravel drive – there’s always something that needs sorting.

Though resin-bonded surfaces cost less initially, those repair bills add up quickly.

For most UK homeowners, especially those planning to stay put, resin-bound surfaces offer better value despite the higher upfront cost.

Weed Resistance and Control

Resin-bound surfaces offer better weed resistance than resin-bonded ones, thanks to their solid, gap-free structure.

Whilst resin-bonded driveways might look similar, their loose stone finish creates spaces where weeds can take root, much like a gravelled path.

You’ll spend less time pulling weeds with a resin-bound surface, making it a more practical choice for busy UK homeowners who want minimal garden maintenance.

Weed Resistance Comparison

Comparing Weed Control: Resin-bound vs Resin-bonded Surfaces

Resin-bound surfaces offer superior weed resistance thanks to their seamless finish – much like a solid patio without the usual gaps between slabs. The surface lets rainwater drain through whilst keeping weed seeds from taking root.

Think of it as a protective barrier that weeds simply can’t break through.

Resin-bonded surfaces, however, tend to be more troublesome. Their scattered stone finish creates tiny spaces where weeds can grow, similar to a gravelled driveway.

When leaves and soil get trapped between the stones, they create perfect spots for unwanted growth.

For long-lasting weed control, resin-bound surfaces are the better choice. They need less maintenance and keep looking tidy, whilst resin-bonded surfaces often need regular weeding as stones come loose and plants force their way through.

Maintenance Effort Required

Resin-bound and resin-bonded surfaces need different amounts of maintenance.

Resin-bound surfaces are easier to maintain, much like a sealed driveway, as their smooth finish prevents weeds from taking root. Think of it as having a protective shield that keeps unwanted growth at bay.

Resin-bonded surfaces, however, require more attention. Their loose stones and gaps make them prone to weeds popping up between the stones – similar to a traditional gravel driveway. You’ll need to check these surfaces regularly and clear away leaves and debris that could encourage weed growth.

Both surfaces benefit from an occasional blast with a pressure washer, but resin-bonded surfaces often need extra care. They’re more likely to flake and require repairs, rather like an old paint job that needs touching up.

This makes them more time-consuming and costly to maintain than their resin-bound alternatives.

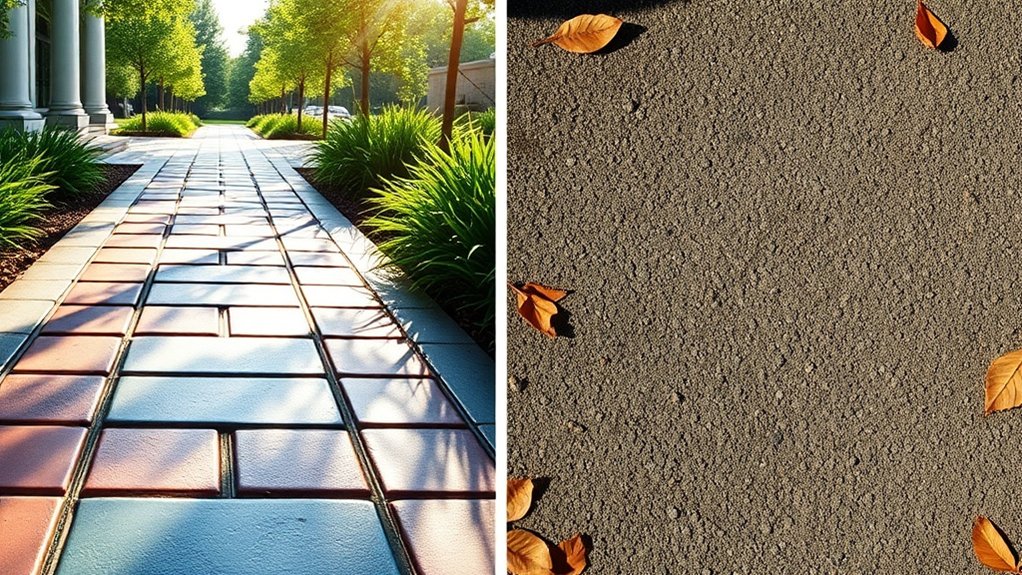

Surface Stability and Stone Migration

Resin-bound and resin-bonded surfaces differ significantly in their stone stability.

Resin-bound surfaces, where stones and resin are thoroughly mixed, create a solid, even surface that’s less likely to crack or deteriorate – much like a well-set concrete path. These surfaces typically last 20-30 years with basic care. Think of it as mixing sugar thoroughly into your tea versus sprinkling it on top.

Resin-bonded surfaces, however, simply have stones scattered over resin, rather like loose gravel on glue. This approach often leads to stones coming loose and creating patchy areas, especially in high-traffic spots like driveways.

You’ll likely need regular top-ups to replace lost stones.

For long-term stability and minimal maintenance, resin-bound surfaces are clearly the better choice. They might cost more initially, but you’ll spend far less time and money fixing loose stones over the years.

Weather Durability and Frost Resistance

Resin-bound surfaces offer superior weather durability and frost resistance thanks to their solid construction. The mixture of resin and aggregate creates a tough yet flexible surface that withstands British weather conditions brilliantly. Much like a well-built winter coat, these surfaces handle freeze-thaw cycles without cracking or breaking down. Traditional resin-bonded surfaces, however, tend to flake and lose stones during harsh weather due to their thinner resin layer.

| Feature | Resin-Bound |

|---|---|

| Weather Durability | High |

| Frost Resistance | Excellent |

| Maintenance Frequency | Low |

A resin-bound surface proves particularly valuable in the UK climate, requiring minimal maintenance whilst delivering lasting durability against rain, frost and seasonal changes.

Cleaning and Surface Appearance

Cleaning and Surface Appearance

Resin-bound and resin-bonded surfaces demand different levels of upkeep, with notable differences in their long-term appearance.

Resin-bound surfaces need minimal maintenance:

- Simple brush sweeping

- Occasional wash with gentle soap and water

- Smooth finish prevents leaves and dirt from sticking

Resin-bonded surfaces require more work:

- Rough texture traps debris between stones

- More frequent cleaning needed

- Stones can come loose over time, creating uneven patches

Much like a well-sealed wood deck versus loose gravel, resin-bound surfaces maintain their smart appearance with less effort.

The smooth finish means autumn leaves and general dirt won’t get stuck, whilst resin-bonded surfaces often look patchy and worn without regular attention.

For practical, long-lasting results, resin-bound surfaces prove the more straightforward choice to maintain.

Professional Installation Requirements

Professional installation of resin surfaces requires strict adherence to key requirements for lasting results.

Resin-bound systems need a solid, clean base – typically fresh tarmac or concrete – without cracks or damage. Think of it like laying a carpet: the floor underneath must be perfectly smooth. The sub-base must be properly compacted, particularly when using washed stone, much like preparing foundations for a garden patio.

Resin-bonded surfaces are more forgiving and can handle slight surface irregularities, as they’re applied more thinly. The process involves spreading resin and scattering aggregate – similar to adding sprinkles to wet icing.

Only qualified contractors should tackle these installations, as they understand crucial factors like:

- Correct timing of application

- Suitable weather conditions for curing

- Proper material selection

Getting these elements wrong could lead to expensive failures down the line, much like rushing to paint outdoors just before rain.

The right expertise ensures your surface will stand up to British weather and regular use.

Frequency of Maintenance Tasks

Regular maintenance of resin surfaces significantly affects their durability and looks. Understanding maintenance requirements for resin-bound versus resin-bonded surfaces helps with proper upkeep:

1. Cleaning Frequency: Resin-bound surfaces need a thorough clean just once or twice yearly – about as often as you’d deep-clean your patio.

Resin-bonded surfaces want quarterly cleaning, as loose stones tend to trap leaves and dirt.

2. Weed Control: Resin-bound surfaces rarely see weeds pop up, needing only a yearly once-over – much like checking your garden walls.

Resin-bonded surfaces require checks twice yearly, typically in spring and autumn.

3. Repairs: Resin-bound surfaces are remarkably tough, typically needing Repairs only every 20-30 years.

Resin-bonded surfaces often need fixing every 5-10 years, roughly as often as replacing your fence panels.

4. Re-Coating: Resin-bound surfaces rarely need Re-Coating at all.

Resin-bonded surfaces need a fresh coat every 3-5 years – similar to repainting garden furniture.

Repair Needs After Severe Weather

Understanding how to maintain resin surfaces after harsh weather is vital for British property owners. Different repair methods are needed for resin bound versus resin bonded surfaces.

| Surface Type | Common Issues | Repair Techniques |

|---|---|---|

| Resin Bound | Minor scratches, debris | Apply resin layer, clean debris |

| Resin Bonded | Loose stones, flaking | Spot repair, strip and reapply |

Resin bonded surfaces tend to suffer more during severe British weather, particularly because they trap water, which leads to frost damage. Think of it like a poorly draining garden path that becomes increasingly damaged each winter. Resin bound surfaces fare better as they allow water to drain through, much like a permeable driveway.

You’ll likely need more frequent repairs on resin bonded surfaces after storms, heavy rain or freezing conditions. Regular maintenance checks are especially important during autumn and winter months to catch any damage early.

Overall Aesthetic and Longevity

The Looks and Lifespan of Resin Surfaces

Resin bound and resin bonded surfaces differ significantly in their appearance and durability:

- Resin Bound: A smooth, glossy finish that lasts 20-30 years with basic upkeep – think of a well-polished stone floor.

- Resin Bonded: A rougher, more textured surface lasting 10-15 years, similar to coarse tarmac.

- Colour: Resin bound keeps its uniform colour and texture, whilst resin bonded tends to fade and lose stones over time.

- Weather Resistance: Resin bound withstands frost damage well, but resin bonded often needs repairs as stones come loose.

Resin bound surfaces prove the better investment, offering both smart looks and longer life – particularly valuable for UK driveways and paths exposed to varied weather conditions.

Frequently Asked Questions

Can I Install Resin-Bound Driveways Myself?

Installing resin-bound driveways is possible as a DIY project, though it requires careful planning and attention to detail. Whilst experienced DIYers can manage the task, it’s crucial to prepare a proper sub-base and mix the resin correctly. The work is physically demanding, involving thorough surface preparation, precise material measurements and swift application before the resin sets. First-time installers should start with smaller areas like paths or patios to gain experience before tackling a full driveway.

How Do Climate Conditions Affect Driveway Maintenance?

Climate conditions play a vital role in driveway upkeep across the UK. Different seasons demand specific maintenance approaches – resin-bound surfaces cope well with our wet weather and need less attention, whilst resin-bonded driveways often require extra care to prevent water build-up and frost damage, particularly during harsh winters.

Are There Eco-Friendly Options for Resin Driveways?

Yes, eco-friendly resin driveways offer a sustainable choice for UK homeowners. These surfaces use recycled materials and locally-sourced aggregates, which cut down on transport emissions and waste. Unlike traditional concrete or tarmac, resin driveways last longer and need minimal upkeep – meaning fewer repairs and replacements over time. They’re also permeable, helping manage rainwater naturally and reducing flood risks common in British weather. The result? A practical, environmentally conscious driveway that’s both durable and cost-effective in the long run.

What Are the Best Cleaning Products for Resin Surfaces?

Resin surfaces last 20-30 years when properly maintained. For best results, stick to pH-neutral cleaners and soft-bristled brushes for sweeping. A gentle approach to cleaning, much like caring for a polished worktop, helps preserve the surface. Regular maintenance not only keeps your resin looking fresh but ensures it reaches its full lifespan.

How Does Each Type Impact Property Value?

Resin-bound driveways boost your property’s value by offering a smart, contemporary finish that lasts for years. They’re particularly popular in upmarket areas like Surrey and Berkshire. Resin-bonded surfaces, whilst more traditional-looking, might actually lower your home’s worth over time due to their upkeep costs and tendency to wear – a bit like comparing a modern composite deck to old concrete paving.

Conclusion

Resin-bound surfaces require less maintenance than their resin-bonded counterparts. The seamless nature of resin-bound paving prevents weeds from taking root and makes regular cleaning straightforward – simply sweep and occasionally pressure wash. Resin-bonded surfaces, whilst initially cheaper, tend to need more attention as loose stones can scatter and the surface may develop patches over time. Think of resin-bound as similar to a solid worktop versus resin-bonded as loose gravel held in place – the former naturally needs less looking after. For UK homeowners seeking minimal upkeep, resin-bound is the more practical choice.