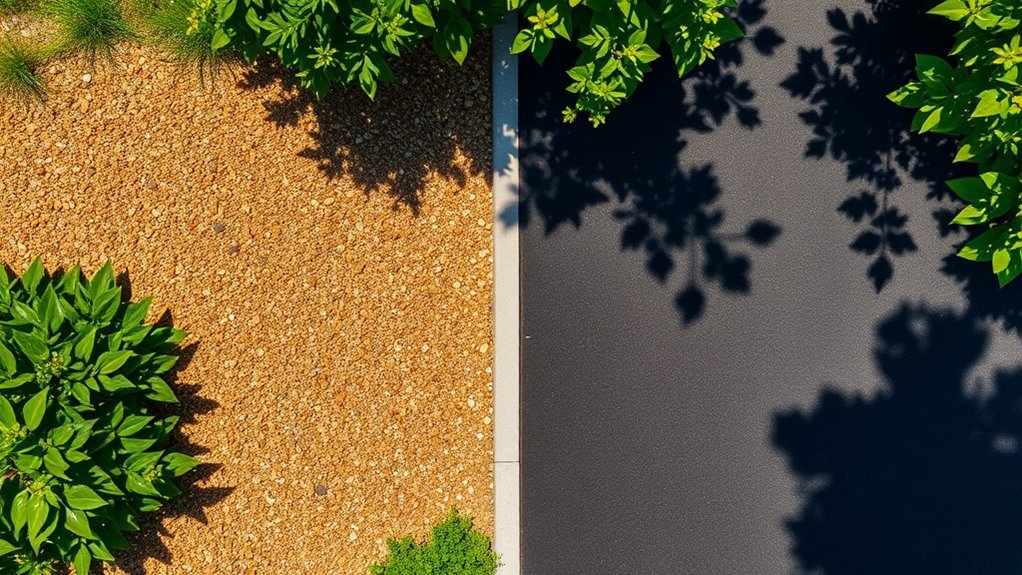

Resin-bound gravel and porous asphalt differ significantly in their performance as permeable surfaces. Resin-bound systems achieve up to 95% water permeability, making them notably more effective than porous asphalt at managing rainwater. Think of it like a garden sieve versus a blocked drain – the resin-bound surface simply handles water more efficiently.

With a lifespan of 15-30 years and minimal maintenance needs, resin-bound gravel proves more cost-effective than porous asphalt, which typically lasts 10-15 years and needs regular upkeep. The resin option also offers far more design choices, from colour schemes to aggregate sizes, whilst maintaining its practical benefits.

Both options suit UK weather conditions, but resin-bound surfaces generally cope better with our wet climate and frequent temperature changes.

Key Takeaways

Resin-bound gravel and porous asphalt offer different solutions for permeable driveways and paths:

Permeability: Resin-bound gravel boasts impressive 95% water drainage, whilst porous asphalt uses a network of channels to direct water below ground.

Lifespan: A resin-bound surface typically serves 15-30 years with basic upkeep – about twice the life of porous asphalt, which needs regular maintenance over its 10-15 year span.

Installation: Fitting resin-bound gravel requires careful hand-laying on a clean foundation, similar to laying patio slabs. Porous asphalt needs heavy machinery and professional crews for compacting.

Cost: Though porous asphalt costs less initially (£2.50-£6 per m²) compared to resin-bound gravel (£9-£14 per m²), the longer lifespan and lower maintenance of resin-bound surfaces often prove more cost-effective.

Appearance: With 46 colour options, resin-bound gravel suits any property style – from traditional cottages to modern homes. Porous asphalt offers basic black with limited design flexibility.

Water Permeability and Drainage

Resin-bound gravel and porous asphalt are top choices for managing rainwater drainage in the UK.

Resin-bound surfaces let water seep through smoothly, much like a coffee filter, whilst their permeable foundation ensures proper water distribution. This resin-bound feature not only promotes effective drainage but also enhances the longevity of the surface. Additionally, resin bound surfaces can achieve permeability rates of up to 95%, making them highly effective for urban water management.

Think of porous asphalt as a sponge – its tiny holes work together to quickly channel water underground, helping replenish groundwater levels.

Both surfaces work brilliantly at preventing puddles and flooding, but they do need looking after.

Regular cleaning with a powerful vacuum, rather like hoovering your carpet, keeps the surfaces working properly. Without this maintenance, they’ll become less effective over time, much like a blocked drain.

These materials offer practical solutions for British weather conditions, though the best choice depends on your specific needs and location.

Durability and Maintenance

Effective rainwater management through permeable surfaces like resin-bound gravel and porous asphalt depends on how well they last and how much upkeep they need.

Resin-bound gravel usually serves 15 to 30 years, whilst porous asphalt tends to last 10 to 15 years – much like the difference between a well-built patio and a standard tarmac driveway.

Resin-bound gravel stands up well to sunlight and rarely cracks, making it particularly hardy. Additionally, it boasts a highly permeable nature that effectively manages rainwater, further enhancing its durability, and is designed to last 15-20 years under typical UK conditions.

It’s simple to maintain too – just sweep regularly and give it an occasional blast with a pressure washer, much like you’d clean your garden path.

Porous asphalt needs more attention, requiring vacuum sweeping and resealing to keep it in good nick.

Both surfaces need quick clean-up if anything spills, but resin-bound gravel is more forgiving and needs fewer harsh chemicals – better for the environment and your maintenance routine. Keeping a low-maintenance surface within a busy outdoor space is essential for long-term upkeep.

Think of it as the difference between caring for a robust garden path versus a more demanding driveway surface.

Installation and Material Characteristics

Installation and Material Guide: Permeable Surfaces

Getting the installation right and knowing your materials is vital for long-lasting permeable surfaces.

Resin-bound Gravel:

- Needs a spotless, flat base

- Uses UV-resistant resin mixed with stone

- Applied by hand-trowelling or pouring

- Offers choice of stone colours and anti-slip options

Porous Asphalt:

- Requires layers of graded stone base

- Mixed and compacted whilst hot on-site

- Needs heavy machinery for proper installation

- Relies on bitumen for strength and durability

Both surfaces need proper slope and drainage planning to handle British weather effectively. Proper ground preparation ensures solid sub-base for optimal adhesion and durability of the final surface, while compliance with UK drainage standards helps to prevent water pooling.

Tip: Choose your installer carefully – proper technique makes all the difference between a surface that lasts 15 years and one that fails after the first frost.

Environmental and Urban Heat Considerations

Urban areas increasingly struggle with heat and water management, making the choice of permeable surfaces crucial.

Resin-bound gravel stands out for its heat-reflecting properties – its light-coloured stones help keep surfaces cooler, much like a white t-shirt on a sunny day. This naturally helps cool surrounding areas and cuts down on air conditioning costs.

Whilst porous asphalt works like a traditional dark road surface, soaking up heat, resin-bound gravel offers better cooling benefits. Both materials let rainwater soak through to the ground, supporting local water tables, but resin-bound surfaces maintain their drainage ability with less fuss.

Think of porous asphalt like a coffee filter that needs regular cleaning – it gets clogged without proper care.

Resin-bound gravel’s lasting durability and eco-friendly materials make it the smarter choice for tackling urban heat and water issues.

It’s a bit like choosing a reliable umbrella that won’t turn inside out in the wind – you get better performance for longer.

Cost and Economic Benefits

Initial costs for permeable surfaces vary considerably – with resin-bound gravel typically costing more than porous tarmac.

Whilst the upfront price of resin-bound surfaces might seem steep, they often prove more cost-effective over time due to lower maintenance needs.

A typical driveway installation shows this well: resin-bound might cost £65-£85 per square metre initially, but requires minimal upkeep compared to traditional surfaces.

Consider both immediate and long-term expenses to make the right choice for your property.

Initial Installation Costs

Initial Installation Costs

Initial costs for permeable surfaces vary significantly, affecting project budgets and long-term value. Key cost factors include:

- Resin-bound gravel: £9 to £14 per square metre, premium cost reflecting higher material quality

- Porous asphalt: £2.50 to £6 per square metre, more budget-friendly option

- Standard gravel: £1.70 to £3.50 per square metre, cheapest upfront but lacks permeability

- Labour requirements: Resin-bound surfaces need specialist installation, pushing costs above porous asphalt

- Customisation: Additional costs apply for coloured or patterned resin-bound finishes

Think of it like choosing between basic gravel for your garden path (cheap but basic) versus a resin-bound surface (pricier but more durable).

These cost differences will shape your investment decision.

Long-Term Maintenance Savings

Cost-effective Maintenance

Selecting the right permeable surface affects both initial costs and long-term maintenance savings. Resin-bound gravel proves more economical than porous asphalt, requiring just weekly brushing and yearly power washing to maintain its quality.

Porous asphalt, on the other hand, needs regular repairs and sealcoating, pushing up both maintenance frequency and costs.

Resin-bound surfaces naturally resist weeds and staining, cutting down on labour and materials needed for upkeep. For example, a typical UK driveway would need far less attention with resin-bound gravel, as moss and weeds struggle to take hold in the sealed surface.

The maths is straightforward: whilst the initial outlay might be higher, choosing resin-bound gravel means fewer repair bills and maintenance costs over your driveway’s lifetime.

Load Bearing and Usage Suitability

When assessing load-bearing capacity, consider both vehicle weight and traffic frequency.

Heavy lorries and regular usage significantly affect permeable surfaces’ structural strength. A proper assessment ensures you choose the right surface – for instance, a residential driveway needs different support than a commercial car park.

Understanding these factors helps select the most suitable option for your project.

Vehicle Weight Considerations

Vehicle Weight Guidelines

Different surfaces handle vehicle weights differently – knowing the load limits keeps your surface safe and lasting.

Resin-bound gravel, when properly laid, supports:

- Standard cars and vans

- Heavy goods vehicles

- Plant machinery and equipment

Essential requirements:

- Solid sub-base for even weight distribution

- 25mm minimum resin thickness (supports up to 7.5 tonnes)

- Open-graded base for strength and drainage

- Professional installation to prevent cracking or dips

Match your surface to the vehicles using it. A lorry depot needs tougher specs than a home driveway.

Both the resin layer and sub-base must be right for the job – cut corners here, and you’ll pay later with repairs.

Think about:

- Heaviest vehicles that’ll use the surface

- How often they’ll cross it

- Weather conditions in your area

Traffic Frequency Impact

Traffic frequency significantly affects how different permeable surfaces perform.

Resin-bound gravel suits light-traffic areas like school paths, garden walkways and home driveways, but isn’t robust enough for heavy use. Though plastic grid systems can boost support, you’ll need regular upkeep to stop debris build-up and maintain the surface.

For busier areas, porous asphalt is the better choice, particularly for car parks and roadways. Its special bitumen mix stands up well to constant vehicle use and British weather conditions.

Choose resin-bound gravel where looks matter and traffic is light, but opt for porous asphalt when you need a tough surface that can handle frequent use.

Aesthetic Options and Customization

Aesthetic Options and Customisation

Resin-bound gravel offers remarkable design flexibility for your outdoor spaces. Its customisation options let you create striking surfaces that work brilliantly for British homes and businesses.

Key features include:

- 46 colour options, from subtle greys to bold terracottas

- Bespoke colour schemes to match your property or company branding

- Modern geometric patterns ideal for contemporary builds

- Traditional designs that complement period properties

- Smart border details using contrasting stones

Whether you’re planning a new driveway, garden path or patio, resin-bound surfaces deliver both practicality and style.

The versatile nature of the material means you can achieve precisely the look you want, from a classic Cotswold finish to a modern London aesthetic.

Frequently Asked Questions

How Do Weather Conditions Affect Installation Timing for Both Surfaces?

Weather conditions play a vital role in installation timing. Monitor temperature and moisture levels carefully – excess damp or incorrect temperatures will affect adhesion and curing. For best results, install on dry days between 10-25°C. Think of it like painting your garden fence: you wouldn’t do it during rain or freezing conditions, as it simply won’t set properly. Poor conditions during installation can lead to reduced durability and performance of your surface.

Can Resin-Bound Gravel or Porous Asphalt Be Installed Over Existing Surfaces?

Roughly 70% of resin-bound gravel jobs need complete surface removal to ensure proper bonding. Whilst porous asphalt can sometimes be laid over existing surfaces, this depends entirely on the stability and condition of the base. Both options require thorough groundwork – much like building a house, the foundation must be spot-on for long-term success.

Are There Specific Regulations for Installing Permeable Surfaces in Different Regions?

Different regions across the UK have their own specific regulations for permeable surface installation. Local councils typically set distinct requirements for planning permission, surface coverage and environmental impact. For instance, London boroughs often require sustainable drainage solutions for new driveways, whilst rural authorities may focus on flood prevention measures. Check with your local planning authority before starting any permeable paving project, as requirements can vary significantly between postcodes.

How Do Permeable Surfaces Impact Local Wildlife and Ecosystems?

Permeable surfaces play a vital role in supporting local wildlife and plant life across Britain. These surfaces allow water to seep through naturally, creating better conditions for native species and plants. Common examples include gravel driveways, grass-reinforced parking areas and porous paving, which help maintain natural water cycles and reduce flooding risks. They’re particularly beneficial for hedgehogs, insects and garden birds, providing essential pathways and feeding grounds. Unlike concrete or tarmac, these surfaces help maintain soil health and groundwater levels, which are crucial for urban and suburban biodiversity.

What Is the Expected Lifespan for Both Materials Under Extreme Weather Conditions?

Under extreme British weather conditions, resin-bound gravel tends to last 15-25 years, whilst porous asphalt typically survives 10-20 years. Both materials face challenges from our harsh climate, including frost damage and heavy rainfall. Regular upkeep, such as annual cleaning and crack repairs, is essential to achieve these lifespans.

Conclusion

When deciding between resin-bound gravel and porous asphalt, it’s essential to match your choice to your needs. Much like choosing between carpet and hardwood flooring, each surface has distinct advantages. Resin-bound gravel tends to suit driveways and garden paths where aesthetics matter, whilst porous asphalt works well for larger areas like car parks. The initial cost might be steeper for resin-bound systems, but their durability and low maintenance often prove worthwhile. Consider your budget, the area’s usage and local weather patterns to make the right choice for your property.