When comparing costs, resin-bound driveways typically range from £60 to £150 per square metre, depending on their size and the quality of materials used. In contrast, resin-bonded driveways usually cost between £40 and £80 per square metre. Keep in mind that installation and site preparation can increase these costs.

Resin-bound driveways are known for their superior durability and drainage capabilities, making them ideal for heavy traffic areas. On the other hand, resin-bonded driveways are better suited for lighter traffic. Interested in learning more about the installation and maintenance of each type? Let’s dive in!

Key Takeaways

Resin-bound driveways typically cost between £70 and £100 per m², while resin-bonded driveways are more affordable, ranging from £40 to £80 per m². For larger projects, resin-bound costs can decrease to around £60 to £90 per m², whereas larger resin-bonded projects may drop to about £50 per m².

Labour costs for both types generally fall between £30 and £70 per m². If you opt for premium resin types for a resin-bound driveway, expect costs to rise to £110–£150 per m², affecting the overall budget. Material costs average £70 per m² for resin-bound driveways, while resin-bonded materials vary based on the decorative aggregates chosen.

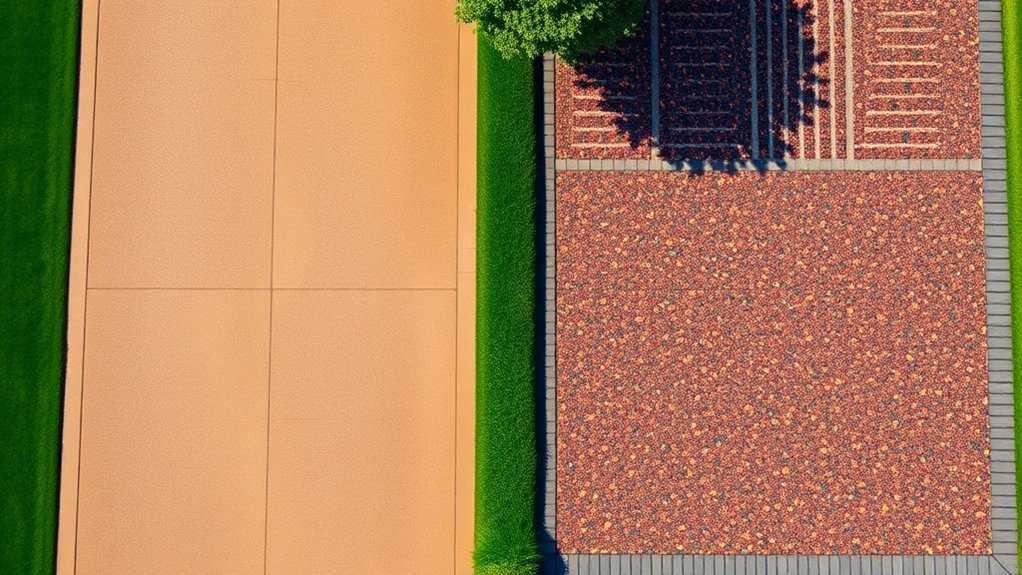

Overview of Resin-Bound and Resin-Bonded Driveways

When choosing a driveway, it’s important to understand the differences between resin-bound and resin-bonded systems.

Resin-bonded driveways involve laying down a layer of resin on a solid base, then scattering aggregate stones on top to create a textured finish. Resin bonded systems can minimize movement of the stones due to the resin’s adhesive properties. Furthermore, the durability of this type of surface can be impacted by heavy traffic, leading to potential long-term wear.

On the other hand, resin-bound driveways mix resin—such as clear polyurethane or epoxy—with aggregate before installation, resulting in a smooth, seamless surface. Installation methods also vary significantly. Resin-bound surfaces are permeable, allowing for proper water drainage and meeting Sustainable Drainage Systems (SuDS) guidelines. In contrast, resin-bonded surfaces are non-permeable, which can lead to drainage problems.

Cost Breakdown of Resin-Bound Driveways

Understanding the cost breakdown of resin-bound driveways is crucial for homeowners in the UK. The average price ranges from £70 to £100 per square metre (m²). For larger driveways of 100m² or more, costs can drop to between £60 and £90 per m². Conversely, smaller areas, such as 20m², typically incur costs between £80 and £120 per m² due to higher fixed costs. If you’re opting for premium resin types, expect prices to rise to £110–£150 per m². Generally, material costs amount to around £70 per m², while labour can range from £30 to £70 per m². Several factors can influence these costs, including the size of the driveway, the groundwork needed, and the type of resin selected, which impacts both durability and appearance. The average cost of a medium-sized resin bound driveway in 2025 is estimated to be around £6,000. Proper installation by skilled installers ensures lasting results and justifies their fees.

Cost Breakdown of Resin-Bonded Driveways

Resin-bonded driveways provide a cost-effective alternative to resin-bound options, typically costing between £40 and £80 per square metre. Key factors influencing the overall price include labour, material quality, and site conditions. For larger projects, costs can drop to around £50 per m² due to economies of scale. Labour costs range from £30 to £70 per day, depending on the complexity of the driveway and any access issues. If site preparation or the removal of old surfaces is needed, expect additional charges. The choice of materials, particularly decorative aggregates, can also impact your overall expenses. Additionally, installation costs may differ between resin-bound and resin-bonded systems, especially considering different site preparation requirements that can influence labour and material needs.

Installation Requirements for Resin-Bound Driveways

To successfully install a resin-bound driveway, focus on key requirements that ensure durability and performance.

First, prepare the surface by clearing away any vegetation, dust, and debris. Excavate to a depth of 150-220mm for a solid sub-base, using Type 1 MOT stone or compacted limestone.

Mix polyurethane resin with a 3:1 aggregate ratio in a forced action mixer for a consistent blend.

Apply the mixture at a minimum thickness of 18mm, using trowels or rollers for an even finish.

It’s crucial to monitor environmental conditions; only install on dry surfaces and when temperatures are above 3°C above the dew point for the best results.

Installation Requirements for Resin-Bonded Driveways

When considering a resin-bonded driveway, it’s essential to ensure your existing surface is suitable, whether it’s concrete, asphalt, or another stable material.

The installation process is straightforward but requires careful preparation for a lasting finish.

Suitable Existing Surfaces

A suitable existing surface is essential for the proper installation of resin-bonded driveways. You’ll need a solid base, such as concrete, asphalt, or tarmac. Any cracked or damaged surfaces should be replaced.

It’s crucial to prepare the surface effectively; ensure the base is clean, dry, and free of debris to promote good resin adhesion. If your base is non-porous, make sure to incorporate drainage solutions to prevent water accumulation, which can damage the resin layer.

Ideally, the existing surface should be porous to allow for proper water drainage and comply with Sustainable Urban Drainage System regulations. A well-prepared base not only extends the life of your driveway but also reduces the risk of cracking due to instability or poor drainage.

Overlay Installation Process

To install a resin-bonded driveway successfully, follow these key steps to ensure proper adhesion and durability.

Begin by preparing the existing surface; it should be clean, dry, and primed. Use edging tape to safeguard adjacent areas.

Next, choose your materials and mix the resin components thoroughly using a forced action paddle mixer, adding aggregates gradually for consistency.

When applying the resin-aggregate mixture, work in sections, using trowels with steady pressure to achieve an even surface finish. Aim for a thickness of 18-30mm, taking into account any substrate reinforcement you may need.

Finally, keep a close eye on the curing conditions. Initial curing will take around 8 hours, while complete curing requires at least 48 hours.

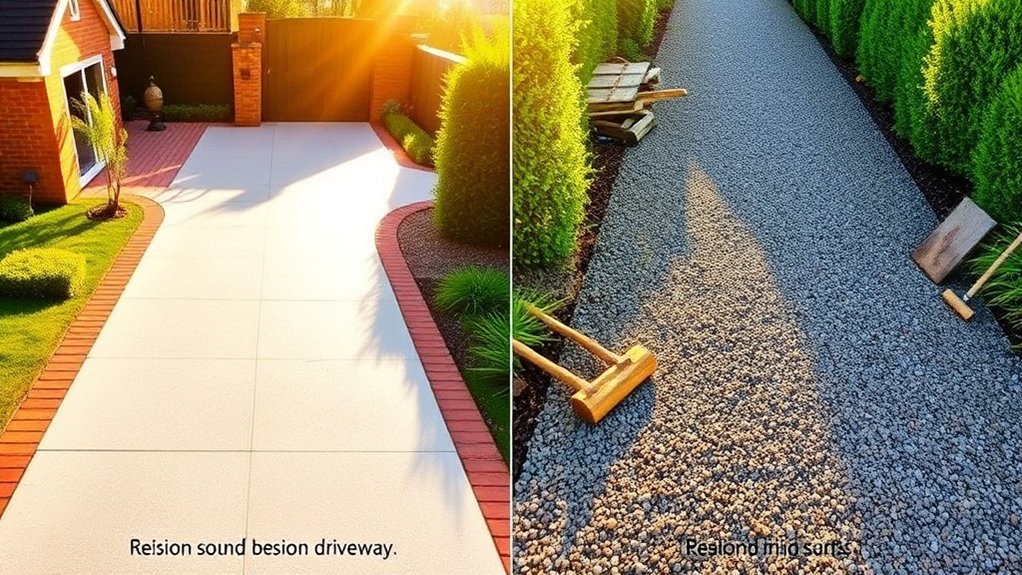

Durability Comparison: Resin-Bound vs. Resin-Bonded

When it comes to durability, resin-bound driveways generally outperform resin-bonded options, lasting between 20 to 25 years with proper maintenance, compared to the 10 to 21 years typical for resin-bonded surfaces.

Resin-bound systems are also better at resisting weather-related damage, reducing problems like stone migration and water pooling.

Knowing these differences can help you make the right choice for your driveway.

Lifespan and Maintenance Needs

Both resin-bound and resin-bonded driveways are durable options for your property, but they differ in lifespan and maintenance requirements.

Resin-bound driveways can last between 15 to 30 years with good materials and care. In contrast, resin-bonded surfaces generally last around 10 to 15 years due to their less stable structure, which is more susceptible to wear.

When it comes to maintenance, resin-bound driveways need annual attention, such as sweeping and pressure washing.

Resin-bonded surfaces may require more frequent maintenance to address loose aggregates. It’s crucial to tackle stains promptly for both types, but resin-bound driveways are less likely to crack, which can save you from costly repairs in the long run.

Weather Resistance and Durability

Both resin-bound and resin-bonded driveways are known for their weather resistance and durability, but they handle environmental challenges differently.

Resin-bound surfaces are highly durable in various weather conditions thanks to their porous, flexible structure. This allows for efficient water drainage, which reduces the risk of cracking during freeze-thaw cycles and helps them cope with temperature fluctuations without damage.

On the other hand, resin-bonded driveways are less porous, which can lead to water pooling and potential surface degradation.

While both types resist the displacement of aggregates in harsh weather, resin-bound driveways generally perform better, minimising issues such as moss growth and erosion.

Understanding these differences can guide you in making the right choice for your property.

Surface Characteristics and Performance Analysis

Resin-bound driveways offer several advantages over traditional options, primarily due to their impressive surface permeability. This feature allows water to drain efficiently, minimising puddles and ensuring compliance with Sustainable Urban Drainage Systems (SuDS) regulations.

Aesthetically, resin-bound surfaces provide a smooth, seamless finish that can replicate various stone textures, all while ensuring a tidy appearance.

Durability is another strong point; these driveways are resistant to cracking and wear from traffic, and they hold up well against harsh weather conditions. Their UV stability also helps maintain their appearance and performance over time, making them a practical and attractive choice for any property.

Maintenance Needs for Resin-Bound Driveways

Maintaining a resin-bound driveway is simple and requires minimal effort to keep it in top condition.

Regular sweeping and the occasional wash can significantly improve its durability and appearance.

This easy maintenance not only keeps the surface looking fresh but also helps maintain its structural integrity for years.

Minimal Cleaning Requirements

Resin-bound driveways are great for their minimal cleaning needs, making maintenance straightforward. A weekly sweep helps prevent debris accumulation and staining.

For a deeper clean, use water or a pressure washer twice a year to prolong the driveway’s life. To keep the surface pristine, use a stiff brush for leaves and set your pressure washer below 2000 PSI.

Address spills promptly to avoid lasting marks, and for stubborn stains, opt for biodegradable cleaners. Don’t forget seasonal care, like clearing drainage channels, to maintain permeability.

Long-Term Durability Benefits

Many driveways experience wear and tear over time, but resin-bound driveways provide long-lasting durability that makes them stand out. Their robust yet flexible surface adapts to ground movement, significantly reducing the risk of cracking and keeping maintenance to a minimum.

This flexibility, along with UV-stable materials, enhances cost efficiency by potentially extending the driveway’s lifespan to over 20 years with proper maintenance.

Installation is quick, so you can enjoy your new driveway sooner. Regular inspections and sealant applications will help maintain its integrity.

Additionally, the impermeable surface resists weeds and stains, meaning less upkeep for you. By choosing a resin-bound driveway, you’re opting for a solution that proves cost-effective and durable in the long run.

Maintenance Needs for Resin-Bonded Driveways

To keep your resin-bonded driveway in excellent condition, regular maintenance is essential. Aim to sweep it weekly with a stiff broom to remove leaves and debris, which helps prevent staining and buildup.

For cleaning, use a hose or a jet wash, ensuring you hold the pressure washer flat and about 20cm from the surface.

Seasonal upkeep is important too. In winter, use a plastic shovel to clear snow and opt for calcium chloride for ice instead of rock salt, as the latter can damage the surface.

Address spills quickly to avoid permanent stains; household detergents are suitable, but steer clear of harsh chemicals.

Don’t forget to maintain drainage channels to stop pooling, and regularly clean to control weed and moss growth.

For a deeper clean, consider hiring a professional every few years to keep your driveway in top shape.

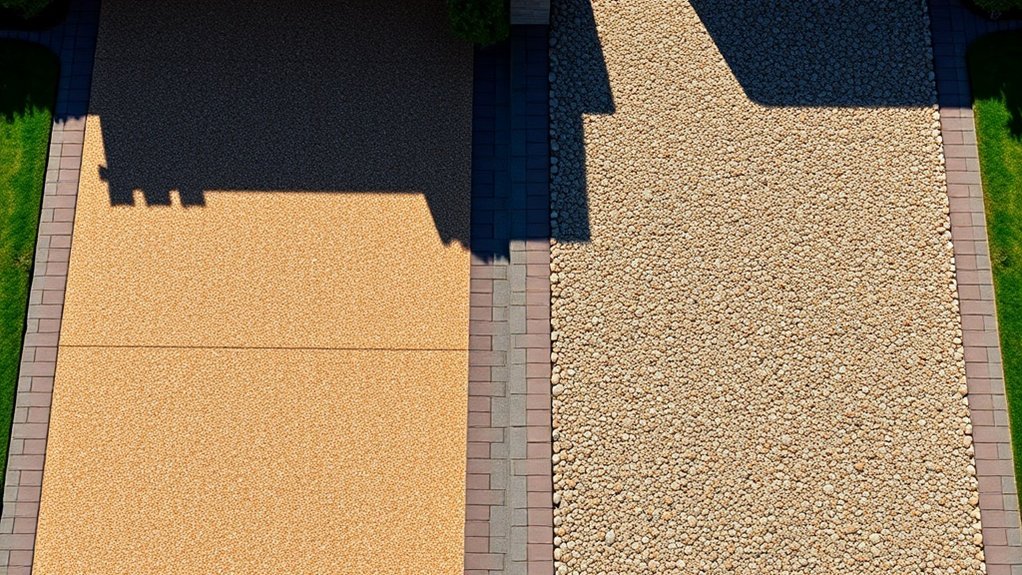

Suitability and Application of Each Driveway Type

Understanding the suitability of resin-bound and resin-bonded driveways is key to making the right choice for your property.

Resin-bound driveways are perfect for residential areas, offering design flexibility and excellent drainage. They handle moderate vehicle traffic well and meet Sustainable Urban Drainage Systems (SuDS) standards.

On the other hand, resin-bonded driveways are better for footpaths and light traffic zones, prioritising appearance over durability. They’re less permeable, making them less suitable for regions with heavy rainfall.

For optimal performance, resin-bound driveways need a permeable sub-base, while resin-bonded surfaces can often be laid over existing driveways with little fuss.

Frequently Asked Questions

Can I Install a Resin-Bound Driveway Myself?

Yes, you can install a resin-bound driveway yourself, but there are a few things to consider. Make sure you have the right tools and equipment, such as a mixer and trowel. Proper preparation is key, so follow guidelines for mixing and applying the resin carefully. For instance, ensure the surface is clean and level before you start. With the right approach, you can achieve a professional-looking finish.

How Long Does Installation Take for Each Type?

Installation duration for both types usually takes between 3 to 4 days. However, factors such as the complexity of the project, surface design, and weather conditions can significantly affect the time required for preparation, application, and curing. For instance, a simple flat surface may take less time compared to one with intricate patterns or features.

What Colors Are Available for Resin Driveways?

There are over 40 vibrant colour options for resin driveways, including warm earth tones and modern greys. These trends enable you to create unique patterns that enhance the look and practicality of your outdoor space.

Are Resin Driveways Eco-Friendly?

Yes, resin driveways are eco-friendly! They use sustainable materials and incorporate recycled components, which helps reduce environmental impact. Their permeable nature allows for effective water drainage, supporting natural water cycles and making them a better choice than traditional surfaces.

How Do Weather Conditions Affect Installation?

Weather conditions can significantly impact installation processes. It’s essential to consider temperature and moisture levels; excessive heat can make materials brittle, while high moisture can cause curing issues. Always check the weather forecast and aim for suitable seasons for installation to ensure quality results.

Conclusion

When deciding between a resin-bound and resin-bonded driveway, think about what suits your needs and budget best. Imagine driving over a smooth, durable surface or enjoying a textured finish that sparkles in the sunlight. Both options have their advantages, but costs and installation processes differ. Your choice should align with your style and lifestyle, ensuring your driveway boosts your home’s curb appeal and lasts well over time.