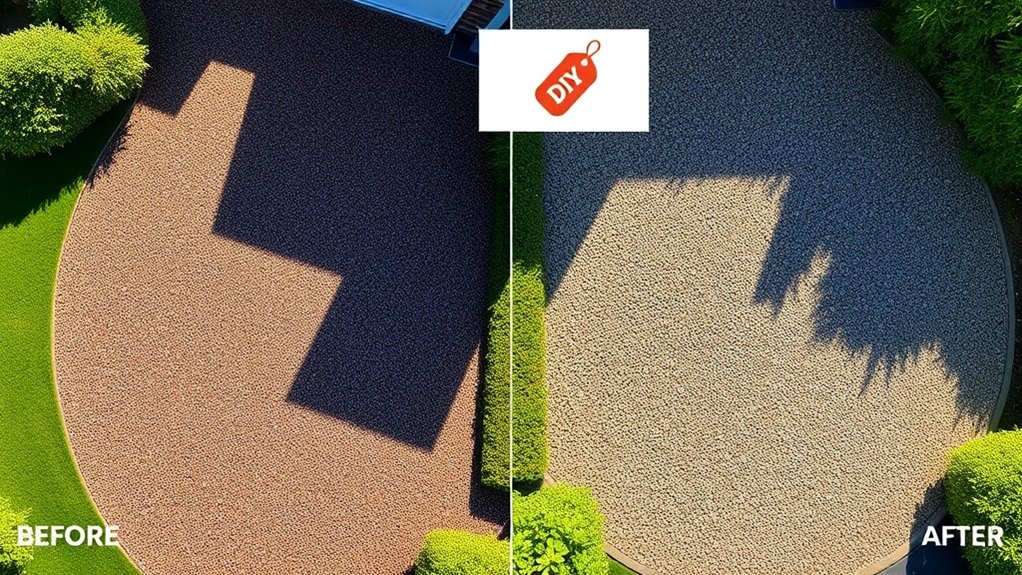

When it comes to the durability of resin-bound gravel installations, professional jobs significantly outlast DIY attempts. Professionals use high-quality, UV-stable resins that can last 20 to 30 years, whereas DIY kits often contain inferior materials that wear out much quicker. Moreover, experts ensure proper base preparation and application techniques, which enhance longevity and drainage efficiency. On the other hand, DIY projects can lead to inconsistent results and expensive errors. If you’re keen to learn more about the different installation methods and their effects, keep digging into the details.

Key Takeaways

- Professional installations use high-quality, UV-stable resins that last between 20 to 30 years, offering superior durability compared to DIY kits.

- DIY kits often contain lower-grade resins that can break down more quickly, leading to a shorter lifespan.

- Professionals ensure proper base preparation and curing techniques, which help prevent moisture problems and improve drainage.

- With professionals, you can expect consistent results that meet SUDS standards, whereas DIY projects may have mistakes that compromise durability.

- Regular maintenance, such as sweeping and pressure washing, is crucial for maintaining the longevity of both professional and DIY resin-bound gravel installations.

Understanding Resin-Bound Gravel

Understanding resin-bound gravel is key to appreciating its benefits in contemporary landscaping and construction. This material is made from dried aggregates such as gravel, crushed stone, or quartz, mixed with a high-performance polyurethane resin. The resin offers UV stability and non-yellowing properties, ensuring durability and an attractive appearance. Additionally, proper substrate preparation is essential for longevity and durability, resulting in a robust surface layer that’s typically 12–24 mm thick. The mixing process in a forced action mixer guarantees uniform application. Furthermore, resin-bound gravel is permeable, which helps reduce surface runoff, contributing to flood prevention and meeting Sustainable Drainage Systems (SuDS) requirements. This permeability allows for effective rainwater drainage, making it ideal for both residential and commercial properties. Overall, the combination of practicality and visual appeal makes resin-bound gravel a popular choice for a variety of uses.

Key Differences in Durability

When comparing professional and DIY installations of resin-bound gravel, the differences in durability are quite pronounced. Professionals use high-quality, UV-stable resins that can last 20-30 years, while DIY kits often feature lower-grade resins that deteriorate more quickly. The right material choices, including additives and the correct aggregate-to-resin ratios, enhance the surface’s strength and flexibility, which helps prevent cracking. Additionally, professionals excel in base preparation and curing techniques that mitigate moisture problems, a common issue with DIY projects. As a result, professionally installed resin-bound gravel offers a more durable and dependable surface than DIY alternatives. Moreover, proper base preparation is crucial for effective drainage, which further contributes to the longevity of the installation. This is particularly important because the surface needs to be level and dry to ensure optimal resin adhesion during the installation process.

Professional vs. DIY Installation

When deciding between professional and DIY installation of resin-bound gravel, it’s important to consider a few key factors, particularly skill and efficiency.

Professionals have the expertise to ensure proper base preparation, resin mixing, and application. Their experience allows for a smoother workflow, which can speed up the project and reduce disruption. This expertise is especially crucial because specialised knowledge can significantly impact the durability and appearance of the installation. Additionally, professionals ensure compliance with SUDS standards to meet drainage regulations, enhancing long-term performance.

On the other hand, while DIY installation might appear cost-effective, it often results in inconsistent outcomes. Achieving the right finish requires specific knowledge and equipment, which many DIYers may lack.

This can lead to a longer project timeline and potential issues with quality and durability. Although you might save on labour costs initially, the risk of costly mistakes can quickly offset those savings.

In most cases, opting for professional installation will provide better quality, efficiency, and long-term satisfaction with your resin-bound gravel surface.

Cost Comparison

When considering the costs of installing resin-bound gravel, it’s important to weigh the options between DIY and hiring professionals to find the most cost-effective solution for your project. Here’s a straightforward cost comparison to help with your budgeting:

| Installation Type | Cost per Square Metre | Key Considerations |

|---|---|---|

| DIY | £45-£70 | Saves on labour costs but could involve tool rental fees. |

| Professional | £80-£120 | Covers expertise, warranties, and often better materials. |

| Material Costs | £40-£50 | Base preparation can affect overall costs. |

| Sealing | £1.25-£1.50 | A budget-friendly maintenance option. |

| Additional Costs | Varies | Complex designs and challenging site conditions can raise expenses. |

This table provides a clear overview, allowing you to make an informed decision about your resin-bound gravel installation.

Maintenance and Upkeep

Investing in resin-bound gravel installation means you’ll need to think about its upkeep to ensure it lasts and performs well. Establishing a maintenance schedule is key.

Regular sweeping with a stiff brush helps remove debris that could cause stains or block drainage. Hosing down the surface with cold water monthly can prevent algae and moss build-up, while pressure washing once or twice a year keeps it looking bright. Just be careful not to use boiling water, as it can damage the resin.

Weeds may pop up, but you can easily remove them by hand or treat them with diluted weed killers.

Seasonal tasks are also important; clear leaves in autumn and apply rock salt in winter to avoid safety issues and surface damage. Regular inspections will help you spot early signs of wear and tear, allowing for timely repairs.

Frequently Asked Questions

How Does Weather Affect the Curing Process of Resin-Bound Gravel?

Weather has a significant effect on the curing process of resin-bound gravel. The ideal temperature for curing is between 15°C and 25°C. If it’s too cold, the resin may not cure properly, while high temperatures can cause it to set too quickly, leading to poor adhesion. Excessive moisture, such as rain, can weaken the bond and result in uneven surfaces or reduced durability. For a successful installation, it’s crucial to ensure the weather conditions are just right.

Can Resin-Bound Gravel Be Installed Over Existing Surfaces?

Yes, you can install resin-bound gravel over existing surfaces. It’s crucial to prepare the surface properly—make sure it’s thoroughly cleaned and that you use the right installation techniques. This will ensure good adhesion and a long-lasting, attractive finish. For example, if you’re laying it over a concrete driveway, ensure there are no cracks or debris for the best results.

What Is the Best Time of Year for Installation?

The ideal times for installation are spring and autumn. These seasons offer moderate temperatures and reduced chances of rain, ensuring optimal curing conditions. This enhances both the durability and appearance of your resin-bound gravel surface. For instance, installing in spring means you can enjoy a fresh look just in time for summer gatherings.

Are There Any Color Fading Issues With Resin-Bound Gravel?

Resin-bound gravel can experience colour fading, much like a painting left in the sun. To combat this, using UV-resistant resins can help maintain the vibrancy of the colours, ensuring your installation stands the test of time and weather.

How Can I Enhance the Slip Resistance of the Surface?

To improve slip resistance, use textured additives such as crushed glass or aluminium oxide during installation. Additionally, applying anti-slip surface coatings can enhance traction, resulting in a safer and more durable resin-bound surface suitable for different conditions.

Conclusion

While DIY resin-bound gravel may seem like an appealing project, it often leads to frustration and quicker deterioration. Professionals possess the skills needed to create a durable surface that far exceeds what most DIY efforts can achieve. Choosing professional installation is not just a decision; it’s an investment in lasting quality. If you want to avoid the disappointment of seeing your hard work fail, going with the experts is the smartest choice for your driveway.