Converting a resin-bonded driveway to resin-bound is entirely feasible. The process starts by removing the existing resin-bonded surface and thoroughly examining the base’s condition. After applying a suitable primer to ensure proper adhesion, a new 15-20mm layer of resin and aggregate mixture is laid. The finished surface offers better durability than its bonded counterpart, stands up well to frost, and looks rather smart. Think of it as upgrading from a standard finish to a premium one – whilst it requires initial investment, the improved drainage and longevity make it worthwhile for many UK homeowners.

Key Takeaways

Converting a resin-bonded driveway to resin-bound is entirely possible, though it requires careful planning and proper installation.

First, you’ll need to strip away the existing resin-bonded surface to check the condition of the base underneath – much like removing old wallpaper before redecorating. Once exposed, the base must be sound and stable.

A specialist primer goes on next to ensure proper adhesion, similar to how you’d prime a wall before painting. The resin-bound mixture, which consists of stone and resin, is then laid on top.

Keep in mind that resin-bound surfaces are typically thicker than resin-bonded ones, so you might need to adjust doorways or drainage heights. Think of it as adding a thicker carpet – you’ll need to account for the extra height.

The end result is worth the effort, as resin-bound driveways offer superior durability and better drainage compared to their resin-bonded counterparts. They’re particularly well-suited to Britain’s wet weather, allowing rainwater to seep through rather than pool on the surface.

Understanding Resin-Bonded and Resin-Bound Driveways

Choosing between resin-bonded and resin-bound driveways boils down to two distinct methods.

Resin-bonded driveways are created by spreading adhesive resin on the surface, then scattering stones on top – rather like creating a giant piece of sandpaper. This gives you a textured finish that looks like loose gravel.

Resin-bound driveways work differently. The stones are mixed with resin first, much like mixing ingredients for a cake, then laid as one smooth layer. Think of it as the difference between sprinkling seeds on bread versus kneading them into the dough. While resin-bonded driveways are cheaper and quicker to install, they’re not as hard-wearing; resin-bound surfaces have excellent structural integrity and tend to last longer and look smarter, though they cost more initially. For British weather, resin-bound surfaces also offer better drainage, preventing those annoying puddles that form after heavy rain.

Your choice might depend on whether you value quick installation and lower costs (resin-bonded) or long-term durability and a smoother finish (resin-bound).

Key Differences Between Resin-Bonded and Resin-Bound Systems

Choosing between resin-bonded and resin-bound driveways comes down to their distinct fitting methods.

With resin-bonded surfaces, workers scatter loose stones onto wet resin, much like applying grit to an icy pavement.

Resin-bound systems, however, mix the stones and resin thoroughly before laying, rather like mixing concrete.

These differences matter for British weather conditions.

Resin-bonded surfaces can shed loose stones over time, particularly after frost, whilst resin-bound driveways tend to stay intact longer.

Think of resin-bonded as wearing a coat with buttons that might pop off, versus resin-bound as wearing a properly knitted jumper – it’s all properly woven together.

For UK homeowners, resin-bound typically proves more durable and requires less maintenance, though it costs more initially. Additionally, resin-bound surfaces boast a superior drainage system, effectively preventing water accumulation.

Resin-bonded offers a cheaper alternative but needs more regular upkeep to stay smart. Both types can last over 10-15 years with proper installation, highlighting the importance of making the right choice.

Installation Methods Comparison

Resin-bonded and resin-bound systems offer distinct installation approaches for driveways.

Resin-bonded installations work like spreading glue and sprinkling stones – you lay resin on a solid base, then scatter aggregate on top. This method is often less durable compared to resin-bound systems, which maintain the correct resin to aggregate ratio for longevity.

Think of it as creating a gravelly surface, though it’s rather weather-sensitive during fitting.

Resin-bound systems blend stones and resin together first, much like mixing concrete. This creates a smoother finish, similar to tarmac but more attractive. You’ll often spot this style at upmarket homes and shopping centres.

The trade-off? Resin-bound takes longer to install, needing careful trowelling for that polished look.

Resin-bonded is quicker but trickier – get the timing wrong, and you’ll end up with patchy spots.

Your choice boils down to looks versus practicality: resin-bound for a premium finish, resin-bonded for a faster, cheaper option.

Durability and Maintenance Differences

The durability and upkeep of resin driveways varies significantly between bonded and bound systems.

Resin-bound surfaces typically last over 25 years, staying robust thanks to their thorough stone-and-resin mixture. Resin-bonded driveways tend to be less durable, with loose stones often coming away and weakening the surface.

Looking after a resin-bound driveway is straightforward – just sweep it regularly and give it an occasional wash with mild soap. Think of it like maintaining a tiled floor.

Resin-bonded surfaces need more attention, requiring regular repairs and dealing with colour fade over time.

Resin-bound driveways handle British weather better, with excellent frost resistance and proper drainage through their permeable surface. You won’t get puddles like you might with traditional concrete. Additionally, the porous surface significantly contributes to effective drainage, minimizing water pooling even in heavy rainfall.

For a low-maintenance, long-lasting option that stands up to UK conditions, resin-bound is the smarter choice.

Structural and Performance Characteristics of Each Type

Resin-bound and resin-bonded driveways offer distinct structural benefits and drawbacks.

Resin-bound surfaces, much like a well-mixed concrete, blend the stones thoroughly with resin, creating a robust surface that handles British winters and regular vehicle use brilliantly. Think of it as a jumper knitted from one continuous thread – it’s all properly connected.

Resin-bonded drives, however, work more like scattered gravel glued to the surface, making them less reliable during frost and more prone to wear, particularly under the weight of family cars and daily use.

Flexibility and Durability Comparison

Flexibility and Durability: A Straightforward Comparison

Resin bound and resin bonded driveways differ significantly in how they handle everyday wear and tear.

Resin bound surfaces:

- Flex naturally with ground movement, much like a springy garden path

- Withstand heavy vehicles without cracking

- Keep their stones firmly in place

Resin bonded surfaces:

- React more rigidly to ground shifts

- Tend to crack under pressure

- Can lose stones over time, particularly in areas like turning circles

For busy family driveways or areas with regular vehicle traffic, resin bound systems prove more practical.

Think of it like a good pair of trainers – flexible yet tough.

Resin bonded works better for lighter use, such as garden paths or decorative areas.

The choice affects both upkeep and looks.

Resin bound requires less maintenance and stays smart longer, whilst resin bonded might need more frequent touch-ups to keep its appearance.

Frost Resistance Analysis

The impact of frost on driveways matters greatly in the UK’s cold weather. Resin bonded surfaces can be problematic, as their non-permeable nature traps water that freezes and expands, often causing cracks and loose stones – much like when a frozen water bottle bursts.

These driveways struggle to cope with typical British winter conditions.

Resin bound driveways offer a better solution. Their permeable surface lets water drain away naturally, rather than pooling and freezing. Think of it like a warm winter coat with breathable fabric – it protects while letting moisture escape.

This design handles freeze-thaw cycles well, maintaining structural strength throughout winter.

For British homeowners, particularly those in frostier northern regions, resin bound driveways prove more practical and cost-effective. They need less upkeep and stay intact longer, making them a smarter choice for our climate.

Installation Process for Resin-Bound Driveways

Installing a Resin-Bound Driveway

A proper resin-bound driveway installation requires careful planning and precise execution. Start with a thorough site check to assess ground conditions and drainage needs – crucial for our British weather.

Essential steps include:

- Base Work: Dig out the area and install a solid sub-base that allows water to drain through. Think of it like laying the foundations for a house – get this wrong, and you’ll face problems later.

- Materials: Pick suitable stone aggregates and UV-stable resin that’ll withstand our climate. Local suppliers often stock weather-tested options.

- Application: Mix the resin and aggregate thoroughly – much like mixing concrete, but requiring more precision.

Spread the mixture whilst it’s fresh, levelling it to 15-20mm depth. A skilled installer will ensure even coverage, rather like icing a cake.

Leave it to cure completely – typically 24 hours in dry conditions – before walking or driving on it.

Remember: rushing the job or skimping on materials will show in the final result. A properly installed resin driveway should last 15-20 years with minimal maintenance.

Maintenance Requirements for Resin-Bonded and Resin-Bound Surfaces

Regular maintenance of resin surfaces keeps them looking smart and working properly.

Both resin-bound and resin-bonded driveways need routine sweeping to shift loose bits and gentle pressure washing to tackle stubborn marks.

Spring and summer call for thorough cleaning, whilst autumn means staying on top of fallen leaves.

Winter requires extra attention to drainage to prevent water pooling.

Watch out for heavy garden furniture or plant pots that might damage the surface, and keep an eye out for weeds trying to push through.

Should you spill anything – particularly oil or chemicals – clean it up straight away with soapy water.

Skip using metal shovels or ice picks in winter, as these can scratch the surface.

A bit of regular care means your resin driveway will stay looking fresh for years to come.

Cost Considerations for Driveway Types

Weighing up costs between resin-bonded and resin-bound driveways requires looking at both installation and upkeep.

Resin-bonded surfaces cost less to install – think £40-60 per square metre – but often need extra drainage work later on.

Much like choosing between a basic and premium car model, resin-bound driveways command a higher price upfront (roughly £70-100 per square metre) but tend to be the smarter investment.

Their better durability means you’ll spend far less on repairs and maintenance over the years, saving you hassle and money down the line.

Initial Installation Expenses

Initial installation costs for resin driveways vary significantly between bonded and bound systems. Key cost factors include:

- Material Requirements: Resin-bound surfaces need precise mixing and a proper sub-base, making them costlier upfront.

- Installation Method: Resin-bonded surfaces can be suitable for DIY installation, helping reduce labour costs.

- Ground Preparation: Resin-bound systems require thorough base preparation, adding to initial costs but ensuring better longevity.

Typical costs run £80-£120 per square metre for resin-bound driveways, whilst resin-bonded options cost £15-£30 per square metre.

Worth weighing these upfront costs against each system’s long-term performance and durability.

Long-Term Maintenance Costs

Long-term maintenance costs for resin driveways are worth considering alongside installation fees. Resin-bound surfaces typically offer good value, lasting 15-25 years with minimal upkeep. Resin-bonded options might cost more over time due to loose stones needing replacement.

Regular maintenance keeps costs down and includes:

| Maintenance Task | Cost Range (£) |

|---|---|

| Weekly Sweeping | £10 – £15 |

| Annual Power Washing | £80 – £150 |

| Resealing (every 2-4 years) | £200 – £550 |

| Crack Repairs | £75 – £500 |

| Aggregate Repair | £120 – £450 |

Quality materials and professional fitting help reduce future maintenance costs. A well-installed resin driveway needs little more than regular sweeping and occasional power washing to maintain its appearance and durability.

The Feasibility of Converting Driveway Types

Converting Resin Driveways: What You Need to Know

Switching from a resin bonded to a resin bound driveway isn’t as simple as laying one surface over another. The process comes with several practical hurdles that need sorting before you start:

- Getting the Surface Right: You’ll likely need to strip off the old resin bonded layer completely – there’s no way around it if you want the new surface to stick properly.

- Checking What’s Underneath: The base layer must be solid and drain well. Most resin bound surfaces need proper drainage, unlike bonded ones, so your current base mightn’t be up to scratch.

- Mind the Height: Resin bound surfaces are typically thicker, which means you might need to adjust your driveway edges to match your garage entrance or garden paths.

Skipping these steps could leave you with a dodgy finish, bumpy surface or drainage nightmares down the line.

Worth getting a professional assessment before cracking on with the job.

Steps for Effective Conversion From Resin-Bonded to Resin-Bound

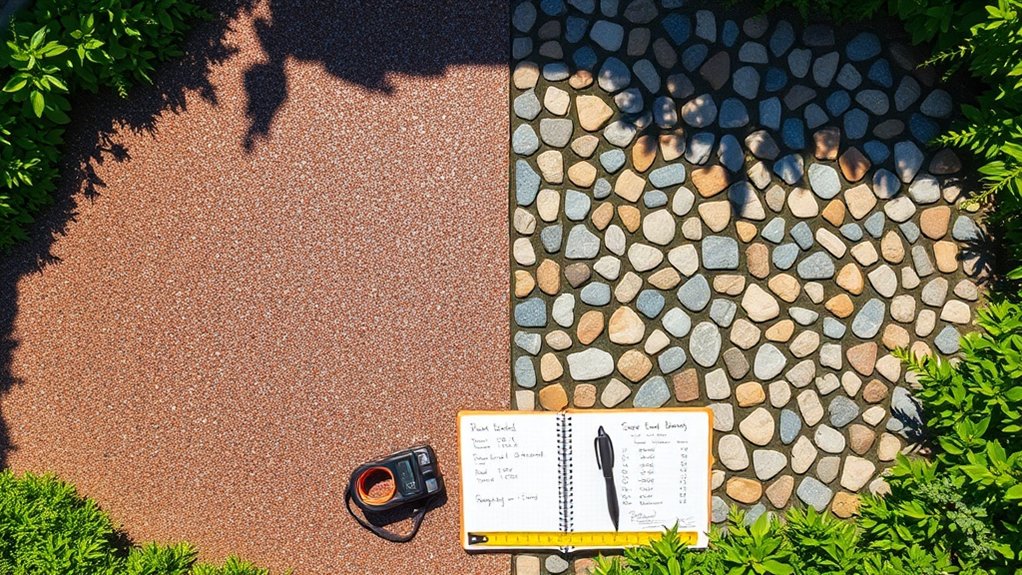

Converting your resin-bonded driveway to resin-bound requires careful planning and proper technique. Start by stripping the old resin-bonded surface using mechanical equipment to achieve a clean base. Check the underlying surface for damage and repair as needed, applying primer where necessary. Mix your chosen resin and aggregates thoroughly in consistent batches. Lay the mixture uniformly whilst keeping an eye on thickness and weather conditions.

| Step | Action | Purpose |

|---|---|---|

| Surface Preparation | Remove old layer, clean base | Ensure solid foundation |

| Base Assessment | Check integrity, apply primer | Boost adhesion |

| Mixture Preparation | Mix resin and aggregates | Ensure lasting finish |

| Application Techniques | Spread evenly, monitor conditions | Achieve professional results |

These steps will deliver a hard-wearing, smart-looking driveway that’ll last for years to come.

Practical Benefits of Resin-Bound Driveways

Resin-bound driveways deliver practical benefits that set them apart for UK homeowners. Their robust weather resistance holds up brilliantly against British weather, from heavy rain to winter frost, whilst their permeable surface prevents water logging and puddles.

The key advantages stand out:

- Long lifespan: Properly installed drives last 15+ years with minimal degradation

- Low maintenance: A quick sweep and occasional power wash keep them looking smart

- Environmental benefits: Built from recycled materials and fully SUDs-compliant for proper drainage

For British property owners, resin-bound driveways offer a sensible investment combining durability, practicality and eco-friendliness – all whilst keeping maintenance costs down and property value up.

Aesthetic Improvements With Resin-Bound Surfaces

Resin-bound driveways offer remarkable visual appeal for your property’s exterior.

With more than 40 colours to choose from and natural stone aggregates like marble and quartz, these surfaces complement any architectural style brilliantly. The multi-toned finishes create genuine depth, whilst UV-stable resins ensure colours stay fresh and vibrant for years.

The sleek, non-slip surface not only looks smart but provides practical safety benefits, particularly in wet British weather.

Think of it like choosing a quality carpet for your home – the right colour and texture make all the difference.

Resin-bound surfaces boost kerb appeal significantly, which can enhance your property’s value when it comes time to sell.

Whether you’ve got a period property in Surrey or a modern home in Manchester, these surfaces deliver a premium finish that sets your driveway apart from standard concrete or tarmac options.

Frequently Asked Questions

How Long Does the Conversion Process Typically Take?

The conversion process typically takes several hours for initial mixing and laying, followed by a 24-48 hour curing period. Exact timings depend on your driveway’s size, British weather conditions and ground preparation. For reference, an average single-car driveway often requires one full day for installation plus two days’ curing time.

Will I Need to Replace My Entire Driveway?

In most cases, a full driveway replacement is necessary. Resin surfaces need a solid foundation to last, much like building a house on strong footings. Patching sections rarely works well, as the old and new areas often develop obvious joins and uneven wear. Think of it like laying a carpet – doing it properly from edge to edge gives the best results.

Can I Install Resin-Bound Myself After Removal?

Installing resin-bound surfacing yourself is possible after removal, though it requires careful attention to detail. Ensure you’ve got a solid sub-base (typically concrete or compacted stone), thoroughly clean the area, and strictly follow the resin mixing ratios. It’s similar to baking – precise measurements and proper preparation are essential for success. Whilst DIY installation can save money, bear in mind that any mistakes could be costly to rectify.

What Happens to the Existing Sub-Base During Conversion?

The existing sub-base needs thorough inspection before conversion begins. Remove any loose stones and check drainage carefully – poor water flow could damage your new resin surface. Test the ground’s firmness and water absorption through standard compaction checks. A well-prepared sub-base acts like a house’s foundations – get it right, and your resin-bound surface will last for years.

Are There Color Options Available for Resin-Bound Surfaces?

A wide variety of colours are available for resin-bound surfaces, from natural stones like Yorkshire Buff and Dorset Gold to bold contemporary shades. Common choices include grey, brown and cream blends that complement both modern and traditional British properties. All colours maintain their appearance well over time with proper installation and maintenance.

Conclusion

Converting a resin-bonded driveway to resin-bound is a practical upgrade that’s worth considering for UK homeowners. Think of it as switching from a standard tarmac drive to a premium surface. Resin-bound driveways offer better water drainage, increased durability and a smarter appearance. The transformation requires proper planning and professional installation, but the end result can significantly boost your property’s kerb appeal and functionality.