UV exposure significantly affects resin-bound gravel colours, causing them to fade as time passes. Vibrant shades like reds and blues tend to fade more quickly than neutral greys and browns. The sun’s rays break down both the resin binders and pigments, resulting in yellowish discolouration and a cloudy appearance.

Much like garden furniture left outdoors, unprotected resin surfaces become brittle and worn. Regular maintenance, including thorough cleaning and resealing, helps protect against UV damage. When choosing materials, opt for UV-stable resins – they might cost more initially but offer better long-term colour retention, similar to how quality outdoor paint lasts longer than budget alternatives.

Key Takeaways

UV rays significantly impact resin-bound gravel colours, with bright shades like Mediterranean blue and sunset orange fading faster than muted tones such as grey or brown.

The combination of sunlight breaking down both resin binders and colour pigments causes surfaces to lose their original sparkle and richness – much like how a garden fence weathers over the years.

To keep your driveway or patio looking fresh, regular cleaning and sealing are crucial. Think of it as applying suncream to protect your skin – the surface needs similar care to maintain its appearance.

Investing in UV-stable resins pays off, as they’re specifically designed for the British climate. These specialised resins resist the yellowing and cracking that often plague cheaper alternatives.

Watch out for additional wear from Britain’s urban pollution and our notorious weather swings. These factors, combined with UV exposure, can speed up colour deterioration, particularly in high-traffic areas like front drives and garden paths.

Understanding UV Exposure and Resin

UV exposure significantly affects resin, causing discolouration – most notably yellowing – in epoxy-based materials. The stability of colours becomes a real issue, much like how garden furniture fades in strong sunlight. Not all pigments cope well with UV light, so choosing the right ones is crucial for lasting results. Think of it like selecting outdoor paint – some hold up brilliantly in British weather, whilst others quickly fade. The same principle applies to resin. The effects of UV light exposure can lead to a loss of gloss and chalking over time, further diminishing the appearance of your surfaces. UV-stable resin, with its ability to prevent fading and discolouration, offers a robust solution to maintain the integrity of your surfaces.

The amount of sunlight and exposure time play key roles, particularly in areas like driveways or garden paths that face constant UV exposure. To protect your resin surfaces, opt for UV-resistant pigments and consider adding protective coatings or UV absorbers. These measures help maintain the original look of resin-bound gravel surfaces, much like how a good wood varnish protects garden decking.

The Impact of UV Rays on Resin Durability

UV rays take a serious toll on resin materials, much like how the sun fades garden furniture over time. Leaving resin exposed to sunlight causes it to weaken and break down, affecting both its strength and surface quality. To protect resin items properly, whether they’re outdoor sculptures or industrial components, it’s crucial to choose UV-resistant formulations or add protective coatings. Environmental factors can greatly influence how well resin withstands exposure, as without proper protection, even the toughest resin will eventually become brittle and discoloured – rather like an old plastic plant pot left out in the garden for too long. Selecting high-quality UV-resistant resin can significantly extend the lifespan of your projects, ensuring they maintain their appearance and durability under harsh conditions, thus reducing long-term repair costs.

UV Ray Effects

UV rays, whilst vital for nature, pose significant risks to resin durability, especially in resin-bound gravel driveways and paths.

Think of UV damage like sunburn on skin – it breaks down the resin’s structure over time, much like how prolonged sun exposure damages our skin. Without proper protection, the resin becomes cloudy and brittle, rather like an old plastic garden chair left out in the sun. The importance of UV stability is evident as it helps prevent yellowing and cracking, which significantly impacts the longevity of the resin surfaces. Furthermore, using UVR resin provides excellent color stability that can withstand harsh conditions.

The colour changes are particularly noticeable in British weather conditions, where sporadic sunny spells can cause patchy fading and yellowing. This is most obvious in areas that get direct sunlight, such as south-facing driveways.

To protect your resin-bound surface, it’s crucial to use UV-stabilised resin from the start.

Regular checks and top-up protective coatings are as important as applying suncream on a hot day. These simple steps help maintain both the look and strength of your resin surface for years to come.

Resin Durability Comparison

Resin durability varies significantly when compared to traditional paving methods in UK conditions. UV-stable resins offer better colour retention and longevity, particularly important given our varying weather. Quality installation makes all the difference – much like laying a proper garden patio, the groundwork must be spot-on.

Whilst concrete and block paving often crack during winter frost cycles, properly laid resin surfaces handle these conditions remarkably well.

Consider this: a typical block-paved driveway might need attention every few years to deal with weeds and settling, but resin-bound surfaces typically need just an occasional sweep and power wash. The initial cost might be higher than traditional paving, but the reduced maintenance often proves cost-effective over time.

For best results, choose UV-stable resins and compatible stones – think of it like matching the right mortar to your bricks.

When properly installed by qualified contractors, resin-bound surfaces can withstand British weather whilst maintaining their appearance for years.

Colour Fading: How UV Affects Vibrancy

UV Effects on Resin-Bound Gravel Colour

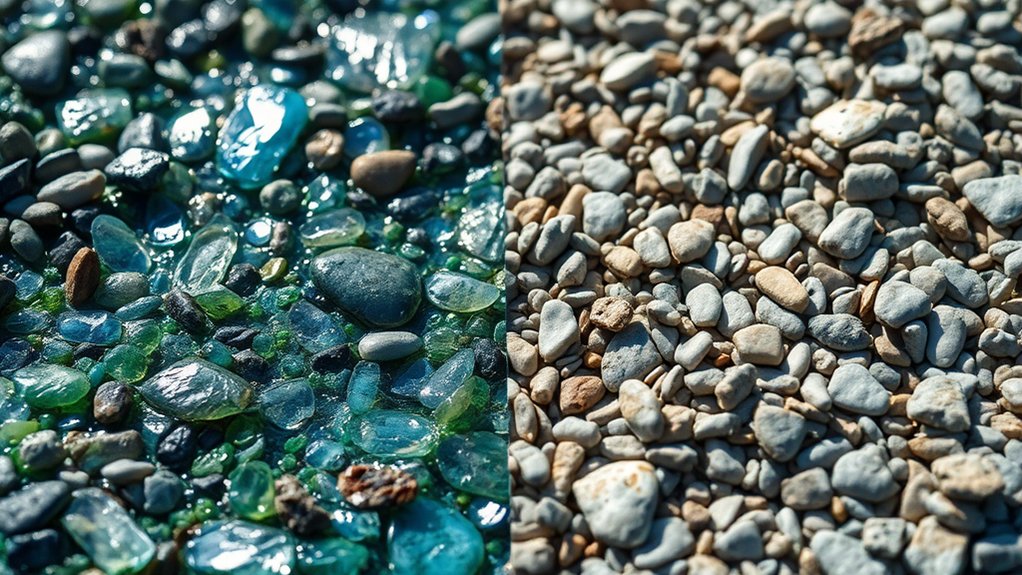

UV exposure significantly affects resin-bound gravel’s colour vibrancy, much like how garden furniture fades in direct sunlight. The sun’s rays break down both resin binders and pigments, causing colours to lose their punch. Brighter colours, such as deep reds and blues, tend to fade more noticeably than neutral tones.

Key factors affecting colour fade:

| Factor | Impact on Colour Fading |

|---|---|

| UV Exposure Duration | Longer exposure increases fading |

| Resin Quality | Non-UV stable resins fade quicker |

| Climate | Intense sunlight accelerates fading |

| Surface Maintenance | Regular care aids fading prevention |

Prevention centres on choosing UV-stable resins from the start and keeping up with maintenance checks. Think of it like applying suncream – proper protection from the outset makes all the difference. Regular cleaning and sealing help maintain the original colour depth, especially in high-traffic areas or spots that catch full sun.

Differentiating Between UV-Stable and Non-UV Stable Resins

Selecting Resins for Outdoor Use: UV-Stable vs Non-UV Stable

UV-stable and non-UV stable resins differ significantly in their outdoor performance:

- Durability: UV-stable resins withstand British weather and sunlight without degrading. Non-UV stable versions tend to yellow and crack when left outdoors.

- Colour Retention: UV-stable resins keep their original colour, whilst non-UV stable options fade noticeably, particularly in summer months.

- Moisture Resistance: UV-stable resins handle rain and humidity well, making them ideal for the UK climate. Non-UV varieties often struggle with moisture exposure.

For British outdoor projects like garden paths or driveway surfaces, UV-stable resins are worth the extra cost.

They’re particularly suited to resin-bound driveways and garden ornaments where long-lasting appearance matters.

The right choice comes down to placement – any outdoor item regularly exposed to sunlight needs UV-stable resin to maintain its look and strength.

The Role of Chemical Structure in UV Resistance

The chemical makeup of resin directly affects how well it stands up to sunlight.

Different types of resin, like styrene-acrylic and cycloaliphatic epoxy, handle UV exposure differently. Cycloaliphatic epoxy resins naturally resist UV damage without extra additives, whilst common aromatic resins tend to break down more easily.

Adding UV absorbers and stabilisers to the resin mix helps it last longer by soaking up harmful rays and preventing damage from free radicals.

For outdoor surfaces like resin-bound gravel driveways, getting this chemical balance right means the difference between a surface that lasts and one that deteriorates quickly.

Environmental Factors Influencing Colour Retention

UV exposure heavily affects resin-bound gravel colour retention, alongside several key environmental factors:

- Pollution and Contaminants: Car fumes, fallen leaves and city grime settle on the surface and cause discolouration. Regular pressure washing keeps these at bay.

- Temperature Fluctuations: British weather swings, from summer heat to winter frost, speed up colour fading, especially with strong sunlight.

- Material Wear: Daily traffic and foot movement wear down the resin’s surface, dulling its original finish.

Understanding these influences helps maintain colour stability and extend your resin-bound surface’s lifespan.

Maintenance Tips for UV-Stable Surfaces

Regular maintenance of UV-stable surfaces requires straightforward cleaning to remove dirt and grime that can affect their sun protection.

A proper UV protectant, available from most DIY shops, offers additional defence against harsh sunlight.

These simple steps keep resin-bound surfaces, such as driveways and garden paths, looking fresh whilst maintaining their protective qualities.

Regular Cleaning Practices

Regular cleaning keeps UV-stable surfaces like resin-bound gravel looking great and working properly.

A good cleaning routine helps maintain colour and extends surface life.

1. Weekly Sweep: Work a stiff brush in circles to shift leaves and dirt – much like sweeping your garden path.

This stops unsightly marks building up.

2. Light Rinse: Give it a gentle spray with your garden hose now and then.

Don’t use pressure washers as they’ll damage the surface.

3. Sort Stains Quickly: Clean up spills straight away with suitable cleaners.

Tea, coffee and oil are common culprits that can leave lasting marks if left untreated.

These simple steps, done regularly, keep your surface in top condition without fuss.

UV Protectant Application

UV protectants play a crucial role in protecting resin-bound gravel surfaces from sun damage.

Modern UV stabilisers can be mixed directly into the resin during installation, much like mixing paint with primer for better coverage. For existing surfaces, a UV-protective topcoat works well – think of it as suncream for your driveway.

Before applying any protectant, ensure the surface is completely clean and dry, just as you’d before painting.

The key is to reapply the protection regularly, typically once every few years or when you notice the surface beginning to look dull.

Check your resin surfaces periodically for signs of UV damage, such as yellowing or fading, particularly in areas that get strong sunlight.

Keeping up with UV protection will save you money in the long run by preventing costly repairs and keeping your surface looking fresh.

Selecting the Right Colours for UV Protection

Choosing Colours for UV Protection

Selecting the right colours for UV protection in resin-bound gravel is straightforward when you focus on these key points:

1. Pigment Selection: Go for UV-stable pigments that won’t fade in British weather.

Think of how garden furniture keeps its colour – you want the same reliability for your resin surface.

2. Colour Blending: Mix colours carefully to match your design whilst maintaining UV protection.

Like mixing paint, but with more emphasis on durability than just appearance.

3. Aggregate Choices: Pick stones and gravel that complement your resin’s UV protection.

Natural greys and browns tend to hold their colour better than bold shades.

These choices matter particularly in exposed areas like driveways and garden paths, where surfaces face constant sunlight and weather exposure.

Long-Term Durability of Resin-Bound Surfaces

Proper UV-resistant colours provide the cornerstone for lasting resin-bound surfaces in British weather.

Quality resins that won’t yellow or deteriorate in sunlight are worth the investment – much like choosing fade-resistant garden furniture.

Installation must be spot-on, as any dips or bumps will affect the surface’s strength over time.

Think of maintenance like caring for your car – regular cleaning and sealing protect against our varied climate, helping surfaces last 15-25 years.

Strong aggregates, similar to those used in premium driveways, boost durability considerably.

When planning your surface, factor in daily use (whether it’s for occasional foot traffic or frequent car parking) and local weather patterns, as these significantly impact how well it holds up over the years.

Cost-Effectiveness of UV-Stable Resins

Cost-Effectiveness of UV-Stable Resins

UV-stable resins are a worthwhile investment for long-term value in resin-bound projects. A direct cost comparison shows:

- Initial Cost: UV-stable resins cost £6 more per square metre – roughly £300 extra on a typical 50-square-metre driveway.

- Maintenance Savings: Less frequent repairs needed, as UV-stable resins resist yellowing and breakdown common in British weather.

- Longevity: Better durability means surfaces stay looking fresh longer, similar to how quality exterior paint outperforms budget alternatives.

The higher upfront cost pays off through reduced maintenance and longer-lasting results, making UV-stable resins the smarter financial choice for permanent outdoor surfaces.

Designing for UV Exposure: Best Practices

Best practices for UV protection in resin surfaces start with proper material matching – your resin must be compatible with your chosen aggregates.

Use UV-resistant coatings to maintain colour stability and prevent fading, particularly important for British weather conditions. Lighter colours like beige and grey tend to show less UV damage than darker shades.

Layer your materials properly – think of it like applying sunscreen in layers for better protection. A well-layered surface will last longer, much like a quality paint job on your car.

Keep the surface clean and well-maintained; a quick sweep and occasional pressure wash will help protect your investment.

The prep work is crucial – your surface must be completely dry and at the right temperature before application, typically between 5-30°C in UK conditions.

Getting these basics right will significantly extend the life of your resin-bound surface, saving you money in the long run.

These straightforward steps will help your resin surface withstand British sunshine and weather, keeping it looking fresh for years to come.

Frequently Asked Questions

How Can I Test if My Resin Is Uv-Stable?

Test your resin’s UV stability by exposing samples to controlled ultraviolet light following ASTM test methods. Keep an eye on colour changes and check how well the material holds up physically over time. A simple comparison between exposed and unexposed samples will show you how UV-resistant your resin is.

For a basic home test, place a small resin sample outdoors in direct sunlight whilst keeping an identical piece indoors. Check both pieces weekly for three months, noting any yellowing or brittleness in the outdoor sample.

What Are the Signs of UV Damage in Resin Surfaces?

Signs of UV damage in resin surfaces show up as yellowing or fading, much like an old plastic garden chair left out in the sun. The surface becomes brittle and may start to crack or flake, rather like dried paint. These changes weaken the resin’s structure, making it less durable over time.

Can UV Exposure Affect the Texture of Resin-Bound Gravel?

UV exposure can indeed affect resin-bound gravel surfaces, much like how strong sunlight fades garden furniture. Over time, persistent UV rays weaken the resin’s structure, potentially causing the surface to become brittle and worn. This weathering often leads to a rougher texture and might reduce the driveway or path’s overall lifespan.

Do Darker Colours Fade Faster Than Lighter Ones in Resin?

Darker colours actually fade more quickly than lighter ones in resin, contrary to what some might think. This happens because darker pigments typically absorb more UV light, causing them to break down faster. Think of a black t-shirt left in the sun versus a white one – the same principle applies to resin. To protect your resin pieces, regardless of colour, use UV-resistant resins and keep them away from direct sunlight.

Is UV Protection Necessary for Indoor Resin Surfaces?

UV protection proves worthwhile for indoor resin surfaces, particularly in rooms with significant natural light. Whilst not essential for all indoor settings, areas like conservatories and sunrooms benefit greatly from UV-stable resins. Without proper protection, direct sunlight through windows can cause yellowing and degradation over time. Think of a bright conservatory floor or windowsill—these spots need extra defence against UV damage to maintain their appearance and structural integrity.

Conclusion

UV exposure on resin-bound gravel acts much like sunlight on your garden furniture – over time, it can cause colours to fade if not properly protected. UV-stable resins help maintain the original colour and appearance of your gravel surface, similar to how quality outdoor paint preserves your fence or shed. Choosing the right UV-resistant resin means your driveway or path will keep its colour for years, even under Britain’s varied weather conditions. It’s worth investing in quality materials upfront to avoid a patchy, faded finish that might need costly replacement sooner than expected.