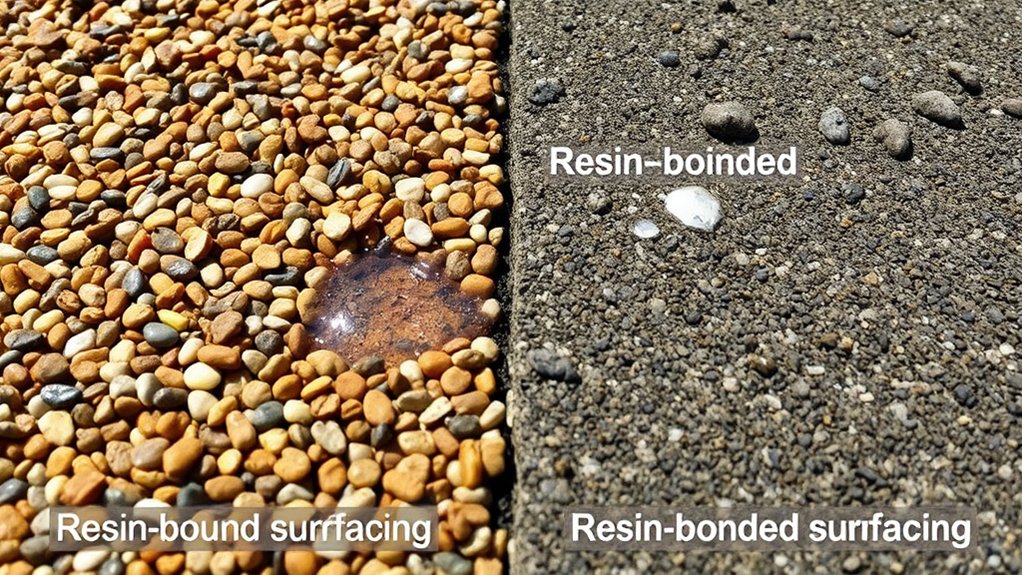

Resin-bound and resin-bonded surfaces differ markedly in several ways. Resin-bound creates a smooth, porous finish – think of a well-maintained garden path – whilst resin-bonded delivers a more gravelly, textured surface common in car parks. For UK homeowners, resin-bound proves particularly practical for driveways, handling our wet weather well through superior drainage. Resin-bonded, though initially cheaper, needs more regular maintenance and can become slippery in typical British conditions. The most striking difference? Resin-bound surfaces allow rainwater to seep through naturally, helping prevent flooding and puddles – a genuine bonus for British gardens and driveways. Resin-bonded surfaces, however, are waterproof and often require additional drainage solutions.

Key Takeaways

Five Key Differences: Resin-Bound vs Resin-Bonded Surfaces

- Resin-bound creates a smooth, seamless finish – think polished pebbles. Resin-bonded looks more like a gravelled driveway with loose stones on top.

- Water drainage is excellent with resin-bound, perfect for British weather, as rain seeps straight through. Resin-bonded creates a waterproof barrier, which might cause puddles during heavy rainfall.

- Resin-bound surfaces typically last 15-40 years with minimal upkeep – just occasional sweeping and washing. Resin-bonded needs more attention and tends to wear down faster.

- Cost-wise, resin-bound is pricier at £85-£130 per square metre, but you get what you pay for. Resin-bonded offers a more budget-friendly option at £35-£50 per square metre.

- Colour stays uniform throughout resin-bound surfaces, whilst resin-bonded might show patchy areas over time, particularly in high-traffic spots.

Application Methods

Resin-bound and resin-bonded surfaces use distinctly different fitting techniques. Resin-bound systems involve trowelling a mixture of resin and aggregate onto a prepared base – much like spreading butter on toast – creating a permeable surface that’s brilliant for driveways and patios. This method is particularly advantageous as it complies with SUDS regulations, promoting effective drainage. Additionally, the UV-stable resin used in resin-bound systems ensures that the surface retains its appearance over time.

Resin-bonded surfaces, however, use a scatter method where loose stones are spread over a layer of resin, similar to sprinkling salt on food. Both need a solid, level base, and timing is crucial. Once mixed, resin-bound materials start setting within 10-15 minutes, so swift application is essential. Think of it like working with quick-drying cement – there’s no time to waste.

The method you choose depends on your needs: resin-bound for a smooth, water-permeable finish, or resin-bonded for a more textured, decorative look.

Aesthetic Differences

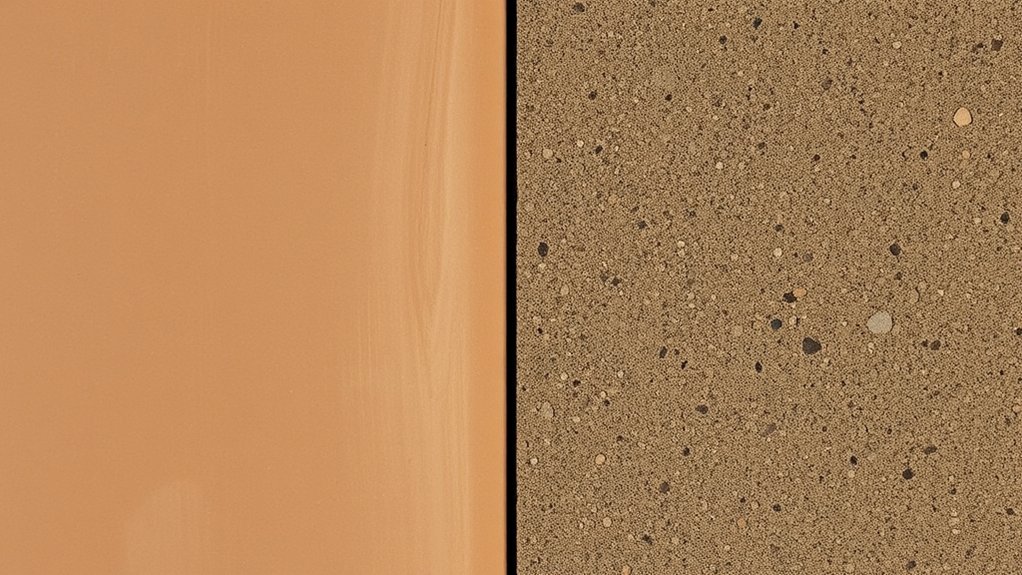

Resin-bound surfaces deliver a smooth, seamless finish, whilst resin-bonded surfaces give a more textured, gravelly look.

Both systems come in various colours and aggregate choices – think everything from natural stone tones to bold modern hues. The difference in appearance means you can match your driveway, patio or walkway to your property’s style, whether that’s a traditional cottage or contemporary home. Additionally, resin-bound surfaces are permeable, allowing water to pass through, which can be beneficial for drainage and reducing water pooling. Moreover, the durability of resin driveways ensures that your chosen aesthetic remains intact for many years, adding lasting value to your property.

Smooth vs. Textured Finish

Resin-bound and resin-bonded surfaces each create distinct looks for your outdoor space.

Resin-bound gives you a smooth, polished finish – think of a modern shopping centre‘s walkways.

Resin-bonded offers a more textured feel, similar to a well-maintained gravel driveway but without loose stones.

Main aesthetic features:

- Resin-bound: Smooth and glossy, perfect for contemporary properties

- Resin-bonded: Traditional gravelled look with excellent grip

- Both options provide slip resistance for wet weather

- Simple to keep clean with basic maintenance

- Resin-bound surfaces are often preferred for their modern appearance in urban settings. Additionally, the durability and longevity of resin-bound driveways make them a sound investment for high-traffic areas.

Your choice should match both your property’s style and practical needs.

For instance, resin-bound suits modern homes and business entrances, whilst resin-bonded works brilliantly for traditional properties and driveways.

Color and Material Variety

Resin-bound and resin-bonded surfaces offer distinct colour and material choices.

Resin-bound systems deliver consistent colouring throughout, as the resin and aggregates are thoroughly mixed – think of a well-stirred pot of paint. You’ll find plenty of colour options, from warm honey-toned gravels to sleek grey blends, common in British driveways.

Resin-bonded surfaces can show slight colour variations, similar to scattered gravel. Both systems work with various aggregates, including local stones and eco-friendly recycled materials.

For long-lasting colour that won’t fade with Britain’s weather, resin-bound surfaces have the edge.

Visual Impact Comparison

Visual Impact: Resin-Bound vs Resin-Bonded

When choosing between resin surfaces, the visual differences are striking:

Resin-bound creates a smooth, contemporary finish – think modern driveways in upmarket neighbourhoods or smart hotel forecourts.

Resin-bonded offers a gravelly, textured look that suits traditional properties and country homes.

The key difference lies in how the stone sits: resin-bound fully encases the aggregate for a seamless finish, whilst resin-bonded leaves stones exposed on top, similar to a gravel drive but permanently fixed.

Choose resin-bound for:

- Modern, sleek appearance

- Smooth, unified surface

Choose resin-bonded for:

- Traditional, rustic charm

- Natural, textured finish

Your choice will significantly influence your property’s kerb appeal – consider which style best matches your home’s character.

Durability and Maintenance

Resin bound surfaces offer superior longevity, typically lasting up to 40 years when properly maintained.

Resin bonded surfaces need more regular upkeep, as stones can become loose over time, particularly where the sub-base isn’t ideal.

Both systems can crack, but resin bound surfaces generally prove more resilient, especially in areas with heavy foot traffic or frequent temperature changes.

Think of the difference between a well-laid garden path that stays intact for decades versus one that needs regular repairs – that’s the practical difference between these two options.

Longevity of Surfaces

Longevity of Resin Surfaces

Resin-bound and resin-bonded driveways offer different lifespans and maintenance requirements. A well-installed resin-bound surface typically lasts 15-40 years, whilst resin-bonded surfaces vary based on their foundation quality.

Key factors affecting durability:

- Resin-bound surfaces resist cracking better, much like a solid piece of tarmac.

- Resin-bonded surfaces need regular stone top-ups, similar to maintaining a gravel drive.

- Both types require proper groundwork, just as you’d expect with any quality driveway.

- British weather and daily use impact how long they last.

For most UK homeowners, resin-bound surfaces prove more cost-effective long-term, needing less upkeep and providing better durability – particularly valuable in our wet climate.

Maintenance Frequency Comparison

Resin-bound and resin-bonded surfaces differ markedly in their upkeep needs. Resin-bound surfaces are remarkably tough, needing just a quick sweep now and then, plus the occasional wash with washing-up liquid. Resin-bonded surfaces, however, need more attention as loose stones can come away over time.

| Surface Type | Maintenance Frequency |

|---|---|

| Resin-Bound | Low; occasional sweeping and washing |

| Resin-Bonded | High; frequent cleaning needed |

| Seasonal Care | Regular upkeep to prevent damage |

| Repair Needs | Less frequent for resin-bound; more for resin-bonded |

A proper maintenance routine, much like caring for your garden path or driveway, will keep both surfaces in top nick and save you time and effort in the long run.

Cracking Resistance Factors

Cracking Resistance in Surfacing

Several key factors determine how well surfaces resist cracking, directly impacting their lifespan and upkeep costs in British weather conditions.

- Durability: Resin-bound surfaces last significantly longer than tarmac or concrete, particularly on driveways and paths.

- Permeability: Proper water drainage stops water pooling and frost damage, common issues in UK winters.

- Flexibility: A slight give in the surface helps withstand ground movement and temperature changes, much like a flexible phone case protects against drops.

- Aggregate Encapsulation: When stones are fully coated in resin, they’re locked in place, rather like tiles properly set in adhesive.

Understanding these factors proves vital when choosing surfacing for British properties, where weather extremes can severely test materials.

Environmental Impact

The environmental differences between resin-bound and resin-bonded driveways are quite stark.

Resin-bound surfaces let rainwater drain through naturally, much like a garden would, which helps prevent flooding and keeps our waterways cleaner. Think of it as a giant sponge that meets UK SuDS requirements, helping to top up groundwater levels naturally.

Resin-bonded surfaces, however, act more like a sealed lid. When it rains, water runs straight off, overwhelming drains and potentially flooding nearby areas – a particular concern given Britain’s wet weather.

These surfaces often develop problems with weeds pushing through and need more upkeep, similar to traditional concrete driveways.

For anyone keen on protecting their local environment, resin-bound is clearly the more eco-friendly choice, working with nature rather than against it.

Practical Applications

Practical Applications

Resin-bound and resin-bonded surfaces serve different purposes across UK properties and public spaces. The right choice depends on your specific needs and site conditions.

Resin-bound:

- Needs a porous base layer for proper drainage

- Creates a smooth, glossy finish

- Perfect for driveways and garden paths

- Common in residential settings

Resin-bonded:

- Works directly on solid surfaces like concrete

- Provides excellent grip in wet conditions

- Ideal for car parks and public walkways

- Popular in commercial areas

The choice between the two often boils down to practical matters.

Resin-bound works brilliantly for home projects where drainage is crucial, whilst resin-bonded suits high-traffic areas where grip is essential, such as shopping centre car parks or school playgrounds.

Permeability and Drainage

The choice of surfacing affects both everyday use and water management.

Resin-bound surfaces allow rainwater to pass through naturally, making them an excellent drainage solution. This permeable design meets UK sustainable drainage (SuDS) requirements and helps prevent flooding.

On the other hand, resin-bonded surfaces create a waterproof layer that blocks water, meaning you’ll need proper drainage systems to avoid puddles.

Think of resin-bound surfaces like a sponge – they soak up water effectively. Resin-bonded surfaces are more like a plastic sheet, forcing water to run off elsewhere.

In Britain’s rainy climate, resin-bound surfaces often prove more practical, especially in flood-prone areas.

These drainage differences play a crucial role in choosing the right surface for your project.

Grip and Safety

Grip and Safety

Resin-bonded and resin-bound surfaces offer different grip levels that affect safety. Resin-bonded surfaces deliver better grip thanks to their rough texture, making them perfect for busy walkways and wheelchair ramps.

Resin-bound surfaces are smoother, which means they might be less reliable in wet or icy weather.

Key points to note:

- Strong grip levels boost safety

- Textured finishes cut slip risks

- Regular upkeep affects safety over time

- Different surfaces suit different uses

For example, a resin-bonded surface would work well for a school playground, while a resin-bound finish might be better for a garden path.

The right choice depends on where you’ll use it and how much grip you need.

Cost Considerations

Cost Considerations

Comparing resin-bound and resin-bonded surfacing costs requires looking beyond basic material prices. Resin-bound driveways typically cost £85-£130 per square metre, reflecting superior quality and longevity.

Resin-bonded surfaces come in cheaper at £35-£50 per square metre – about the price of a decent patio installation.

Installation costs vary significantly. Resin-bound surfaces need expert handling and precise mixing, much like crafting a perfect cake – get it wrong, and you’ll face expensive repairs.

Site preparation, such as laying proper drainage, can bump up costs further.

Think of it like choosing between a basic coat and a premium jacket – whilst resin-bonded is cheaper upfront, resin-bound surfaces often prove better value long-term, needing less maintenance and lasting longer.

For a typical UK driveway of 50 square metres, the difference could be £2,500 versus £6,000, but with notably different lifespans and upkeep needs.

Frequently Asked Questions

How Long Does the Installation Process Take for Each Type?

Installation times differ between systems: resin-bound surfaces take roughly one day to install, plus 24-36 hours to cure properly. Resin-bonded installations are generally faster to apply but still require proper setting time before you can walk or drive on them.

Can I Install These Systems Myself or Hire a Professional?

Whilst DIY installation is possible, roughly 70% of self-installed systems encounter problems from poor setup. A qualified professional brings vital expertise and proper tools, ensuring the job’s done right first time. If you’re handy and willing to research thoroughly, DIY can work – but for peace of mind and guaranteed results, a certified installer is worth considering.

What Is the Lifespan of Each Surfacing Type?

Resin-bound surfaces typically last 15-30 years, whilst resin-bonded options generally have a shorter lifespan. The difference mainly comes down to maintenance needs, how well they’re fitted and British weather conditions. Think of it like comparing a well-laid patio to loose gravel – the more robust installation tends to weather better over time.

Are There Any Specific Tools Needed for Installation?

Basic tools required: trowels, mixers and surface preparation equipment. Having the right tools ensures proper installation and a professional finish. A standard DIY toolkit should include measuring equipment, levelling tools and safety gear for your installation work.

How Do Weather Conditions Affect the Installation Process?

Weather conditions significantly affect installation success. Temperature changes impact resin behaviour, whilst moisture can prevent proper bonding. For best results in the UK climate, install when temperatures are between 10-25°C and humidity is low. Damp or rainy conditions will compromise the final finish, so choose a dry day for your project.

Conclusion

Simply put, choosing between resin-bound and resin-bonded surfacing comes down to practical matters. Think about your driveway or garden path – resin-bound offers better drainage and longevity, whilst resin-bonded tends to be more budget-friendly. For British weather, the permeable nature of resin-bound makes it particularly useful, preventing those pesky puddles we’re all too familiar with. Look at your needs: if it’s a heavily-used area like a car park, resin-bound’s durability might be worth the extra cost. If it’s a decorative garden feature, resin-bonded could do the job nicely. Understanding these differences means you’ll get the right surface for your space and budget.